Sb-SnO2-AgNWs/CBS-GNs flexible thin film solar cell and preparation method thereof

A solar cell, sb-sno2-agnws technology, applied in the field of solar cells, can solve the problems of harsh preparation conditions, narrow application range, and poor flexibility of thin-film solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Sb-SnO 2 -The preparation method of AgNWs / CBS-GNs flexible thin film solar cells, the process is as follows:

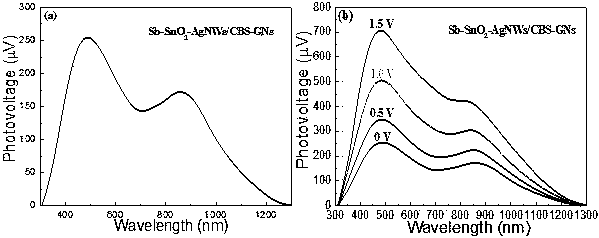

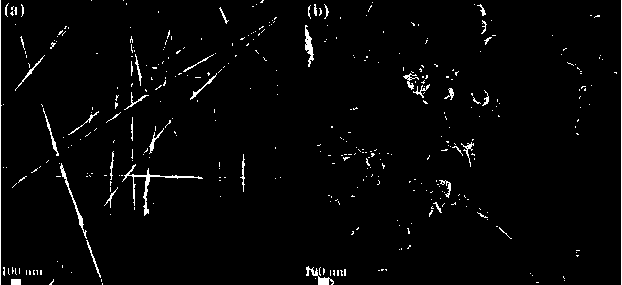

[0026] (1) The purchased poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid (PEDOT:PSS) was deposited (about 15 nm in thickness) onto the PET substrate to improve the contact between AgNWs and the substrate; Fine AgNWs (diameter ≤20 nm) dispersed to 5.5 ml EMIMBF 4 Mixed solution with ultrapure water (volume ratio 1:10), continuously stirred for 10 min to obtain a uniform dispersion of AgNWs (the electron microscope scanning image is shown in the figure below). figure 1 a, indicating that AgNWs in EMIMBF 4 AgNWs solution was deposited on PEDOT:PSS by spin-coating deposition technology, and kept at 80 °C for 1 h to completely evaporate the water, and the AgNWs electrode (thickness was 45 nm) was obtained.

[0027] (2) Put an appropriate amount of SnCl 4 ·5H 2 O was uniformly dispersed in isopropanol, and stirred continuously for 30 min to obtain a 0....

Embodiment 2

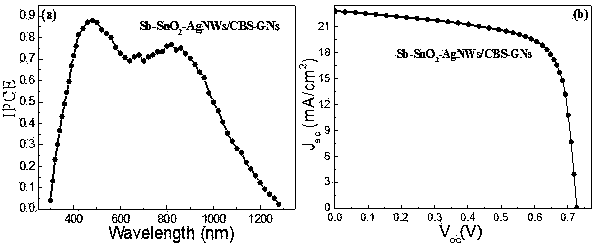

[0031] For Sb-SnO 2 -AgNWs electron transport layer, gradually increase the mass percentage of AgNWs (with Sb-SnO 2 and AgNWs total amount, the addition amount of AgNWs is 0.0, 0.2, 0.4, 0.6, 0.8, 1.0, 1.2, 1.4, 1.6 wt%), the photoelectric conversion efficiency of the corresponding thin-film solar cells shows a trend of increasing first and then decreasing. Example 1: The photoelectric conversion efficiency of the flexible solar cell varies with the mass percentage of AgNWs as follows: Figure 4 (a). It is shown that the introduction of an appropriate amount (0.2~1.6 wt%) of AgNWs can significantly improve the Sb-SnO 2 Electron transport characteristics, the photoelectric conversion efficiency increased from 10.62% to the maximum efficiency of 13.05% (the addition of AgNWs was 1.0wt%), which improved the photoelectric conversion efficiency; (b) Sb-SnO 2 -AgNWs / CBS-GNs photoelectric conversion efficiency retention rate with the number of bending times, the prepared solar cel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com