A kind of mo-titanium dioxide-agnws flexible perovskite solar cell and its preparation method

A solar cell, mo-tio2-agnws technology, applied in the field of solar cells, can solve the problems of limited application range, incompatibility with flexible substrates, etc., to achieve the effect of expanding application range, realizing large-scale preparation, and promoting rapid development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mo-TiO 2 -AgNWs flexible perovskite solar cell preparation method, comprising the following steps:

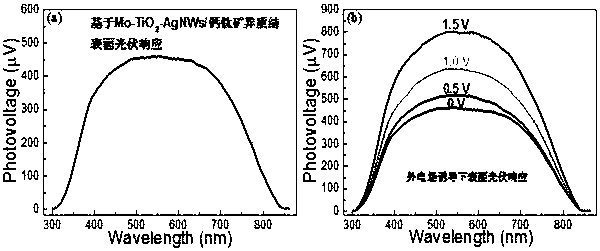

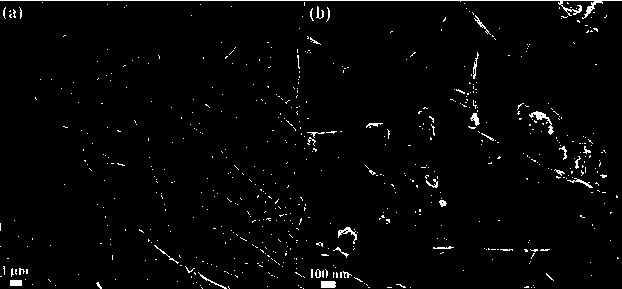

[0035] (1) The purchased poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid (PEDOT:PSS) was deposited (thickness about 15 nm) on the PET substrate to improve the contact between AgNWs and the substrate; 5 mg ultrafine AgNWs (diameter≤20 nm dispersed into 5.5ml EMIMBF 4 and ultrapure water (volume ratio 1:10) in a mixed solution, and continuously stirred for 10 min to obtain a uniform dispersion of AgNWs (the scanning electron microscope picture is shown in figure 1 As shown in a, it shows that AgNWs in EMIMBF 4 The AgNWs solution was deposited on PEDOT:PSS by spin-coating deposition technology, and kept at 80 °C for 1 h to completely evaporate the water to obtain the AgNWs electrode (thickness 45 nm).

[0036] (2) Mo-TiO 2 - Preparation of AgNWs electron transport layer

[0037] a. Dissolve 11.72 g of titanium isopropoxide into 2.4 g of acetic acid solution, ...

Embodiment 2

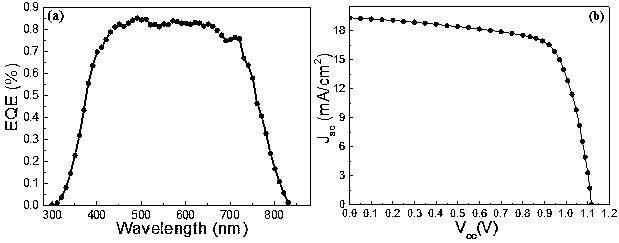

[0045] For Mo-TiO 2 -AgNWs electron transport layer, gradually increasing the mole percentage of AgNWs (based on Mo-TiO 2 and the total amount of AgNWs, the addition amount of AgNWs is 0.0, 0.2, 0.4, 0.6, 0.8, 1.0, 1.2, 1.4, 1.6 mol%, corresponding to the photoelectric conversion efficiency of perovskite solar cells showing a trend of first increasing and then decreasing, and other Same as Example 1, the photoelectric conversion efficiency of the perovskite solar cell changes with the AgNWs mole fraction (mol%) and the relationship curve is as follows Figure 4 (a) shown. It shows that the introduction of an appropriate amount (0.2~1.6mol%) of AgNWs can significantly improve the Mo-TiO 2 Electron transport characteristics, photoelectric conversion efficiency increased from 12.85% to 14.53% (AgNWs addition amount is 1.0mol%), improving photoelectric conversion efficiency; (b) is Mo-TiO 2 - The photoelectric conversion efficiency retention rate of AgNWs perovskite solar cells...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com