Method for increasing color value of capsanthin by using lipase to catalyze ester decomposing

A lipase-catalyzed ester and lipase technology, which is applied in the field of natural product extraction and separation, can solve the problems of small processing volume, product color value decline, and high production cost of capsicum red, achieving the effect of sufficient extraction and guaranteed invariance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

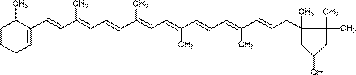

Image

Examples

Embodiment 1

[0034] 1. Pretreatment: In a 500L extraction kettle, add 50kg of treated chili powder, then add 200kg of 70% ethanol aqueous solution, add sodium bicarbonate to adjust the pH value to 7.6, control the temperature at 37°C, and add 0.5kg of lipase (type is Lipase) for enzymolysis. After 2 hours of enzymolysis, the temperature was raised to 70°C, stirred for 1 hour, filtered by rejection, and the filter cake was transferred to a drying oven for drying.

[0035] 2. The first leaching: Add the drying material obtained in the first step into the leaching kettle, add 200kg of n-hexane, control the temperature at 60°C, leaching for 2 hours, turn off the heating, put it at room temperature, filter, and add to the filtrate 100kg of 70% ethanol aqueous solution, stirred for 30 minutes, extracted and separated, and the upper n-hexane layer was concentrated to obtain capsicum red product 1, which was dark red viscous liquid, hardly flowing, and the total content of oleic acid was about 13.4...

Embodiment 2

[0038] 1. Pretreatment: In a 500L extraction kettle, add 50kg of treated chili powder, then add 200kg of 70% ethanol aqueous solution, add sodium bicarbonate to adjust the pH value to 7.6, control the temperature at 37°C, and add 0.5kg of lipase (type is Novozy435), carry out enzymatic hydrolysis for 2 hours, then raise the temperature to 70°C, stir for 1 hour, shake off the filter, and transfer the filter cake to a drying oven for drying.

[0039] 2. The first leaching: Add drying material to the leaching kettle, add 200kg ethyl acetate, start stirring, control the temperature at 70°C, leaching for 1 hour, turn off the heating, put it at room temperature, filter, add 100kg to the filtrate 65% ethanol aqueous solution, stirred for 30 minutes, extracted and separated, and the upper ethyl acetate layer was concentrated to obtain the spicy red pepper product 1, which was a dark red viscous liquid, hardly flowing, and the total content of oleic acid was about 13.8%. GB1886.34-2015...

Embodiment 3

[0042] As in Example 1, in its step 1, lipase Lipozyme RM IM can be added, and the total content of oleic acid is about 14.0% in the first extraction of capsicum red product 1, and the absorbance QUOTE =219, the total content of oleic acid in the second extraction of capsicum red product 2 is about 11.1%, and the absorbance QUOTE =183.

PUM

| Property | Measurement | Unit |

|---|---|---|

| skim rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com