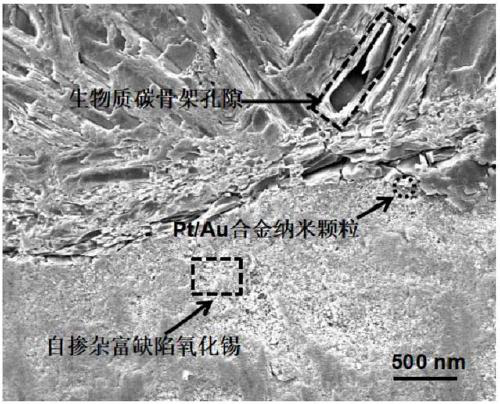

Method for preparing biomass carbon-based metal-modified self-doped vacancy-rich tin oxide nano-composite photocatalytic materials

A technology of photocatalytic materials and biomass carbon, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, tin oxide, etc. Complicated process and other issues, to achieve the effect of controllable shape and size, narrow particle size distribution, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Heat the biomass waste coconut shell from room temperature to 200 °C for 5 hours at a heating rate of 2 °C / min in a nitrogen atmosphere, and cool to room temperature after the reaction to obtain a biomass carbon skeleton;

[0037] 2) get 1mmol analytically pure tin protochloride (SnCl 2 ) and 5mmol of citric acid are fully dissolved in 8mL of absolute ethanol, then add 2mmol of tea polyphenols and 10mL of deionized water successively and adjust its pH value to 8 with 2mol / L NaOH solution to obtain solution A. In the ice-salt bath of NaCl and crushed ice, use a constant temperature magnetic stirring device to carry out continuous magnetic stirring at 10°C;

[0038] 3) get 0.1mmol analytically pure chloroplatinic acid (H 2 PtCl 6 ), 3mmol silver nitrate (AgNO 3 ) and 5 mmol of citric acid were fully dissolved in 8 mL of deionized water, and then mixed uniformly at 10°C with a constant temperature magnetic stirring device in an ice-salt bath of NaCl and crushed ice t...

Embodiment 2

[0043] 1) Under an argon atmosphere, the biomass waste leaves were heated from room temperature to 300 °C at a heating rate of 4 °C / min for 3 hours, and the reaction was completed and cooled to room temperature to obtain a biomass carbon skeleton;

[0044] 2) get 1mmol analytically pure tin protochloride (SnCl 2 ) and 8mmol of citric acid are fully dissolved in 14mL of absolute ethanol, then add 6mmol of tea polyphenols and 21mL of deionized water successively and adjust its pH value to 6 with 5mol / L NaOH solution to obtain solution A. In the ice-salt bath of NaCl and crushed ice, use a constant temperature magnetic stirring device to continuously magnetically stir it at 0°C;

[0045] 3) get 0.3mmol analytically pure chloroplatinic acid (H 2 PtCl 6 ), 2mmol chloroauric acid (HAuCl 4 ) and 8 mmol of citric acid were fully dissolved in 15 mL of deionized water, and then mixed uniformly at 0°C with a constant temperature magnetic stirring device in an ice-salt bath of NaCl and...

Embodiment 3

[0051] 1) The biomass waste banana peel was heated from room temperature to 400 °C for 0.5 h at a heating rate of 8 °C / min in a nitrogen atmosphere, and the reaction was completed and cooled to room temperature to obtain a biomass carbon skeleton;

[0052] 2) get 1mmol analytically pure tin protochloride (SnCl 2 ) and 12mmol of citric acid are fully dissolved in 20mL of absolute ethanol, then add 10mmol of tea polyphenols and 25mL of deionized water successively and adjust its pH value to 4 with 8mol / L NaOH solution to obtain solution A. In the ice-salt bath of NaCl and crushed ice, use a constant temperature magnetic stirring device to carry out continuous magnetic stirring at 10°C;

[0053] 3) Take 1mmol silver nitrate (AgNO 3 ), 6mmol copper nitrate (Cu(NO 3 ) 2 ) and 13mmol of citric acid were fully dissolved in 20mL of deionized water, and then mixed uniformly at 10°C with a constant temperature magnetic stirring device in an ice-salt bath of NaCl and crushed ice to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com