Environment-friendly and low-carbon calcium carbide synthesis process

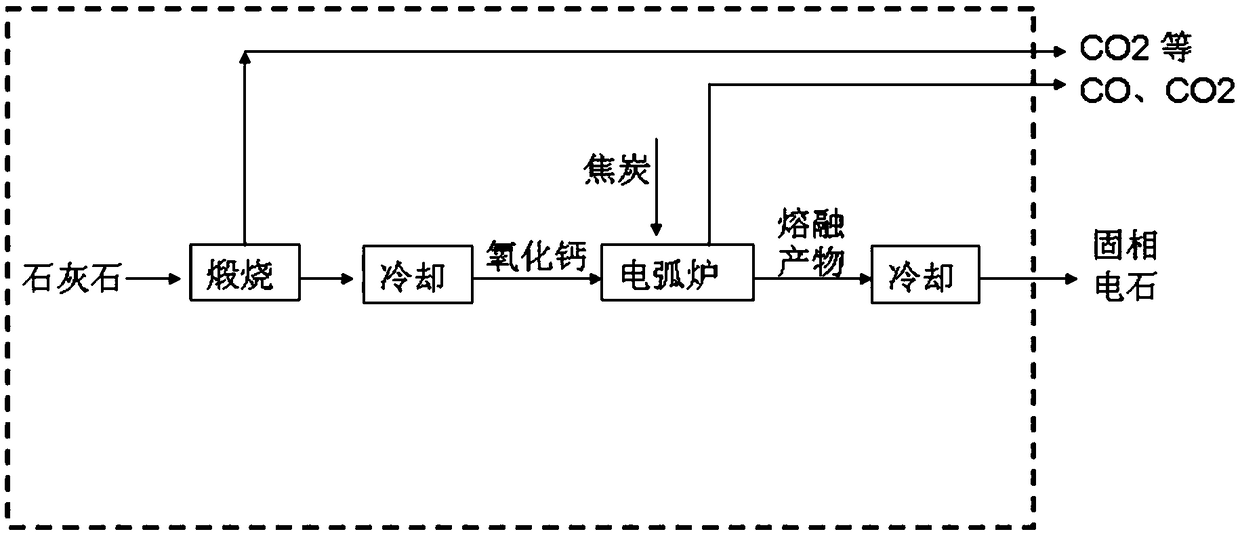

A synthesis process and calcium carbide technology, which is applied in the field of green and low-carbon calcium carbide synthesis process, can solve the problems of high carbon dioxide and emissions, and achieve the effects of improving the quality of calcium carbide, reducing CO2 emissions, and improving the effective utilization of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

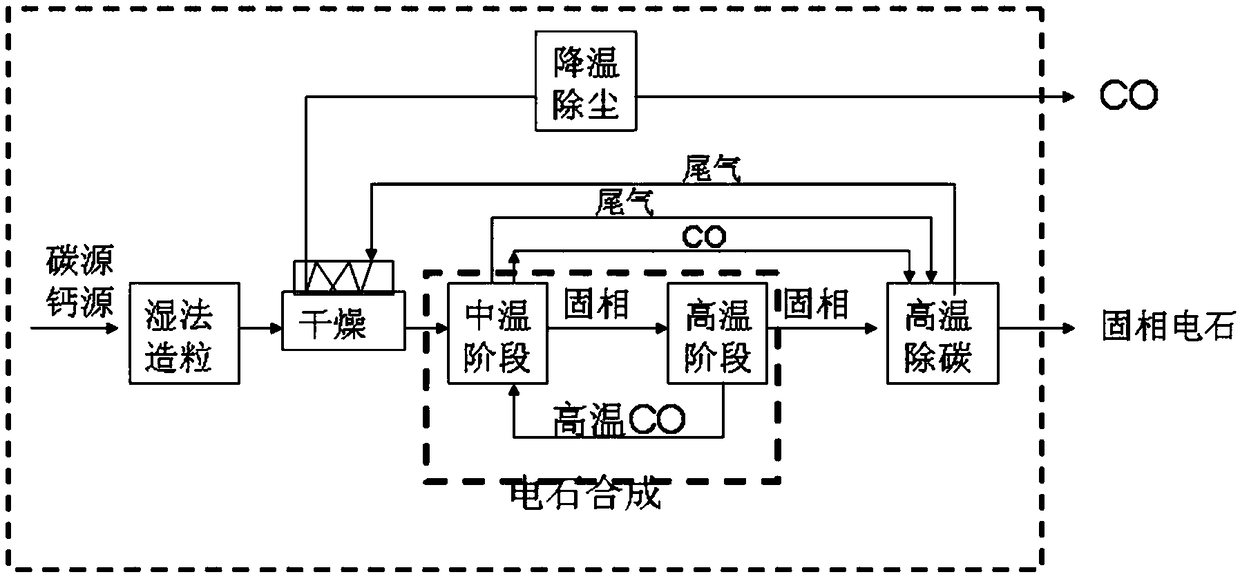

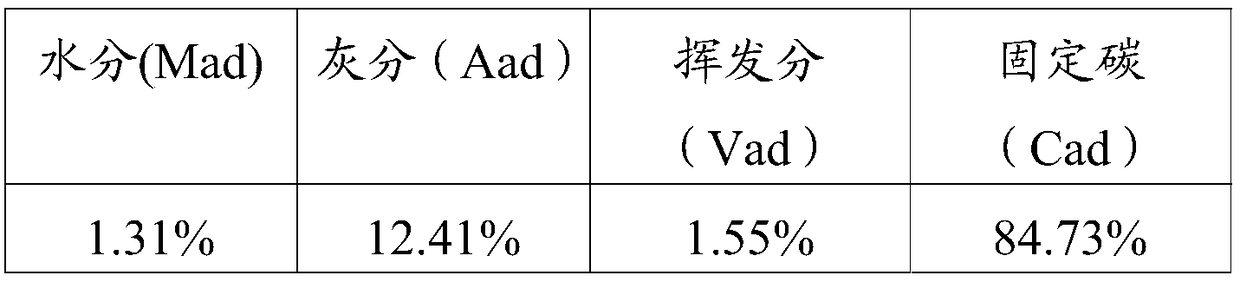

Embodiment 1

[0031] The mixture of powdered metallurgical coke (see Table 1 for the composition analysis of metallurgical coke) and calcium carbonate (the mass content of calcium carbonate is greater than 99.0%) (the molar ratio of carbon to calcium is 4:1) is ultrafinely ground by an ultrafine pulverizer , take the mixed material with a particle size distribution of 50-100 μm and put it into a granulator, use water as a binder, and carry out wet granulation to obtain a round pellet with a size of 1-2 cm as a raw material. After exchanging heat with the tail gas from the high-temperature carbon removal process through the heat exchanger and drying, the raw material group is put into the middle temperature section of the two-stage electric furnace, and the vacuum system of the reaction furnace is opened to discharge the air in the reaction furnace. When the absolute pressure of the system is low After 500Pa, turn on the heating power supply to heat up to 1200°C and keep the temperature const...

Embodiment 2

[0035] Powdered metallurgical coke (see Table 1 for composition analysis of metallurgical coke) and calcite (calcium carbonate mass content 98.0%) mixture (molar ratio of carbon to calcium is 4:1) was ultrafinely ground by a superfine pulverizer, and then obtained The mixed material with a particle size distribution between 100 and 200 μm is put into a granulator, and water is used as a binder for wet granulation to obtain a round pellet with a size of 2-3 cm as a raw material group. The raw material group is passed through After the tail gas from the high-temperature decarbonization process is heat-exchanged and dried, it is put into the electric heating reaction furnace 1, furnace 2 and furnace 3 respectively, and the vacuum system of the reaction furnace 1, furnace 2 and furnace 3 is opened to discharge the air in the reaction furnace. When the absolute pressure of the system is lower than 500Pa, first turn on the heating power of the reaction furnace 1, raise the temperatur...

Embodiment 3

[0037] A mixture of powdered metallurgical coke (see Table 1 for the composition analysis of metallurgical coke) and calcium carbonate (the mass content of calcium carbonate is greater than 99.0%) (the molar ratio of carbon to calcium is 4:1) was granulated into balls by wet method, and the preparation method was the same as in the example 1. Firstly, after the raw material group is heat-exchanged and dried by the tail gas from the high-temperature decarbonization process, it is put into the microwave rotary hearth furnace through the distributor. The air in the reaction furnace, when the absolute pressure of the system is lower than 500Pa, turn on the microwave heater, adjust the microwave power in the middle temperature zone to 1200°C and keep the temperature constant for 30 minutes. After being discharged, it is sent to the high-temperature decarbonization process. The solid-phase product generated by the reaction is sent to the high-temperature zone through the transition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com