High thermal stability titanium dioxide-based ceramic material and preparation method thereof

A technology of high thermal stability and ceramic materials, applied in the field of ceramic materials, can solve the problems of not meeting the application standards of X9F or X9E ceramic capacitors, poor thermal stability of titanium dioxide-based ceramics, high dielectric loss and loss of application value, etc., to achieve low dielectric Power loss, high yield, and strong practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

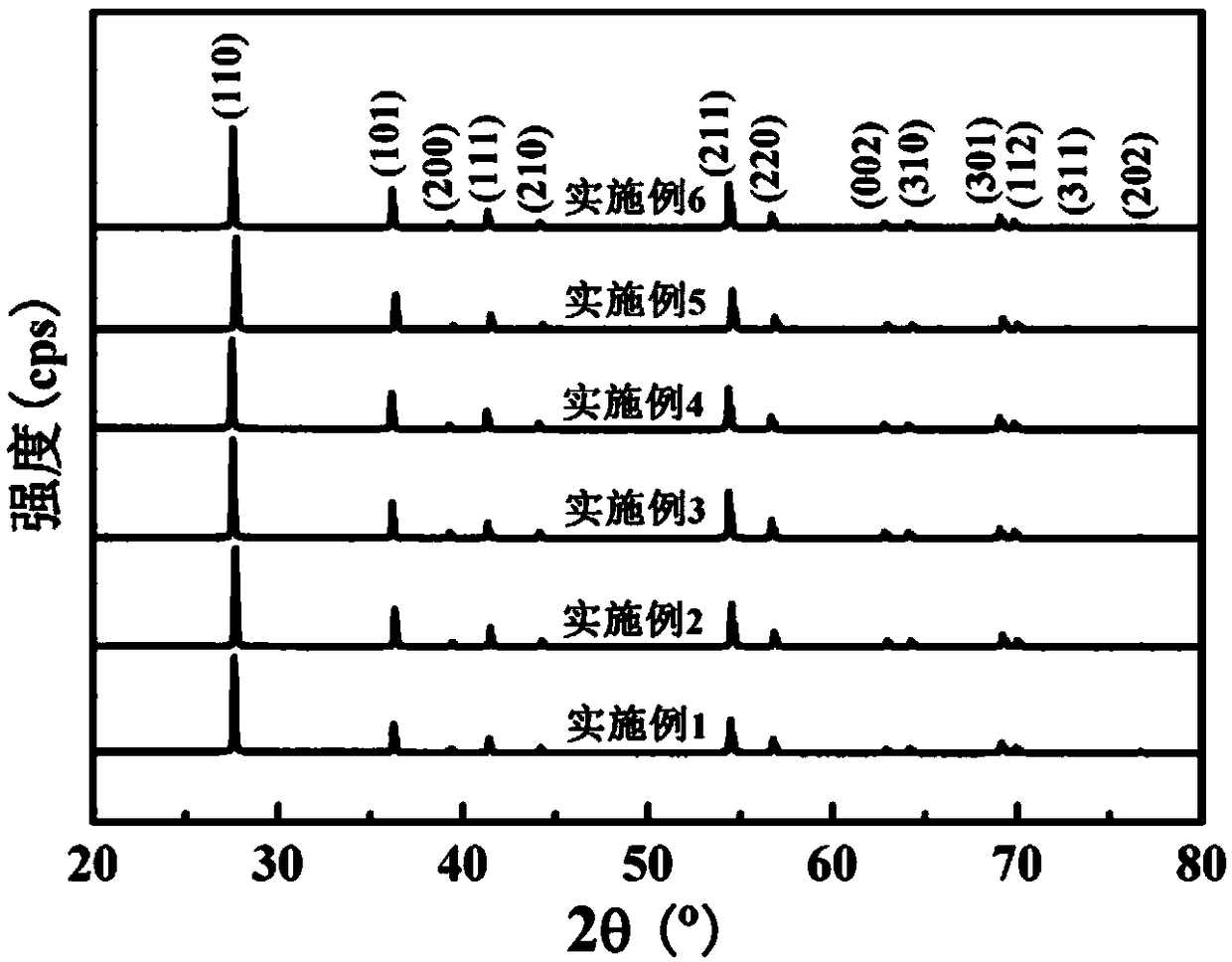

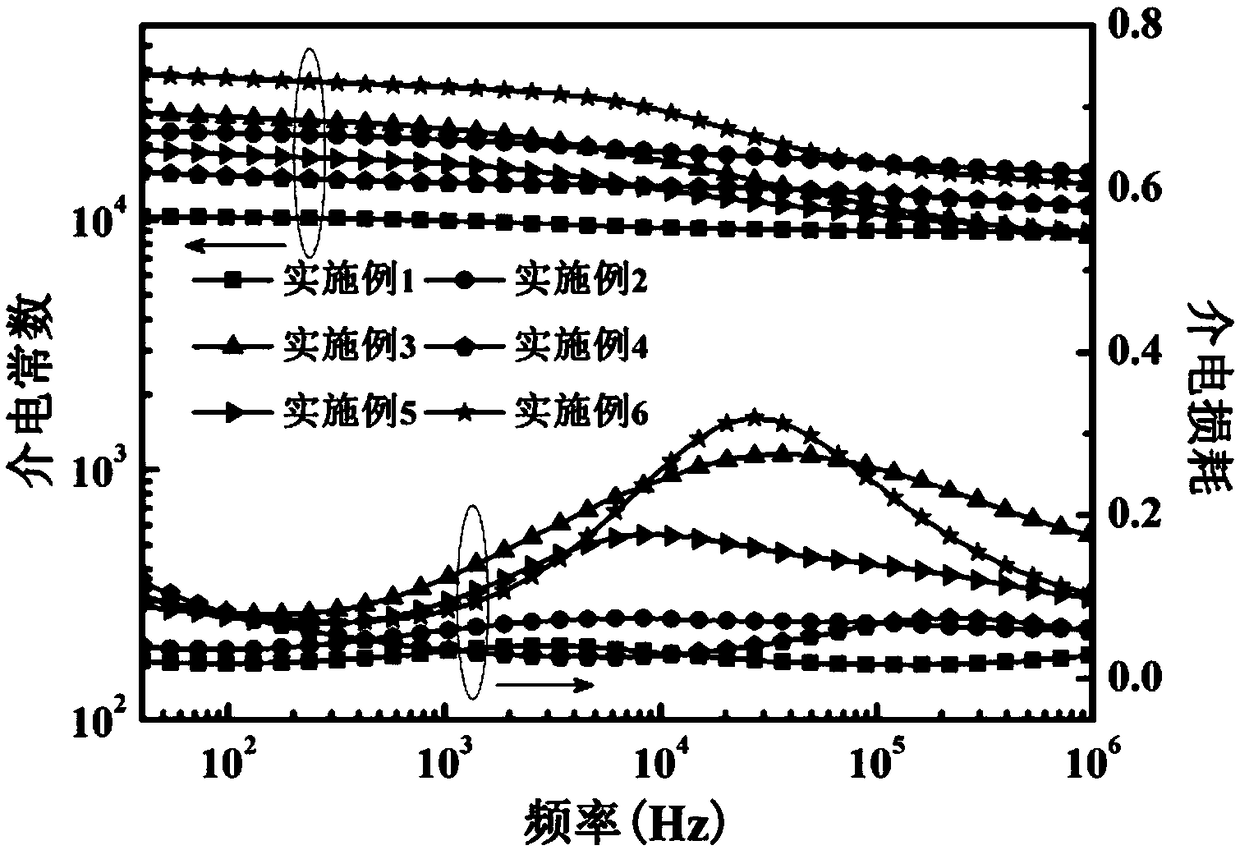

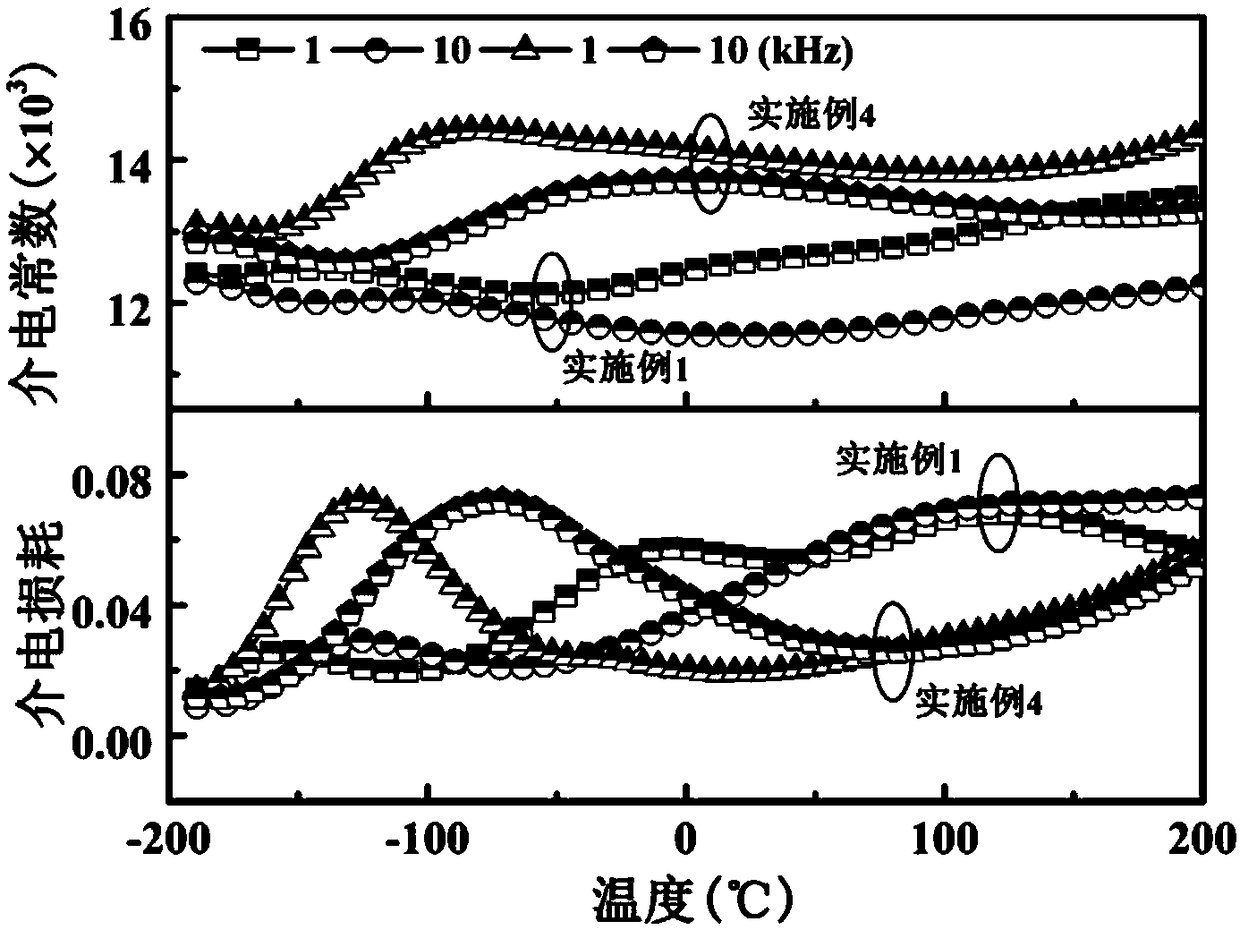

Embodiment 1

[0022] 1. According to (Cu 1 / 4 Nb 3 / 4 ) 0.005 Ti 0.995 o 2 The stoichiometry of raw materials were weighed Cu 2 O (purity 99.9%) 0.0222g, Nb 2 o 5 (purity 99.99%) 0.1238g, TiO 2 (purity 99.5%) 19.8539g, and pack in the nylon tank, be ball milling medium with zirconium ball, dehydrated alcohol, the mass ratio of dehydrated alcohol and raw material mixture is 1:1.2, ball mills with ball mill 401 revolutions per minute After 24 hours, the zirconium balls were separated, the raw material mixture was dried at 80° C. for 24 hours, and ground with a mortar for 30 minutes to obtain a raw material mixture.

[0023] 2. Put the raw material mixture in an alumina crucible, cover it, heat it up to 1100°C at a heating rate of 3°C / min and keep it warm for 3 hours, cool it down to room temperature naturally, take it out of the furnace, and grind it with a mortar for 5 minutes to obtain a calcined powder.

[0024] 3. Put the calcined powder into a nylon tank, use zirconium balls as gri...

Embodiment 2

[0026] In this embodiment, according to (Cu 1 / 4 Nb 3 / 4 ) 0.01 Ti 0.99 o 2 The stoichiometry of raw materials were weighed Cu 2 O (99.9%) 0.0444g, Nb 2 o 5 (99.99%) 0.2471g, TiO 2 (99.5%) 19.7085g, in the air atmosphere in the tube furnace, under airtight conditions, the temperature is first raised to 1000 °C in 100 minutes, and then the temperature is raised to 1350 °C at a heating rate of 2 °C / min, and the temperature is kept for 10 hours. Other steps and implementation The same as in Example 1, a titania-based ceramic material was obtained.

Embodiment 3

[0028] In this embodiment, according to (Cu 1 / 4 Nb 3 / 4 ) 0.02 Ti 0.98 o 2 The stoichiometry of raw materials were weighed Cu 2 O (99.9%) 0.0883g, Nb 2 o 5 (99.99%) 0.4920g, TiO 2 (99.5%) 19.4196g, in the air atmosphere in the tube furnace, under airtight conditions, the temperature is first raised to 1000 °C in 100 minutes, and then the temperature is raised to 1360 °C at a heating rate of 2 °C / min, and the temperature is kept for 10 hours. Other steps and implementation The same as in Example 1, a titania-based ceramic material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com