Gypsum-based plastering mortar

A plastering mortar and gypsum-based technology, applied in the field of gypsum-based plastering mortar, can solve problems such as poor performance of gypsum products, separation of board core and paper core, and few reports, and achieve resource utilization and strong cohesion. , the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

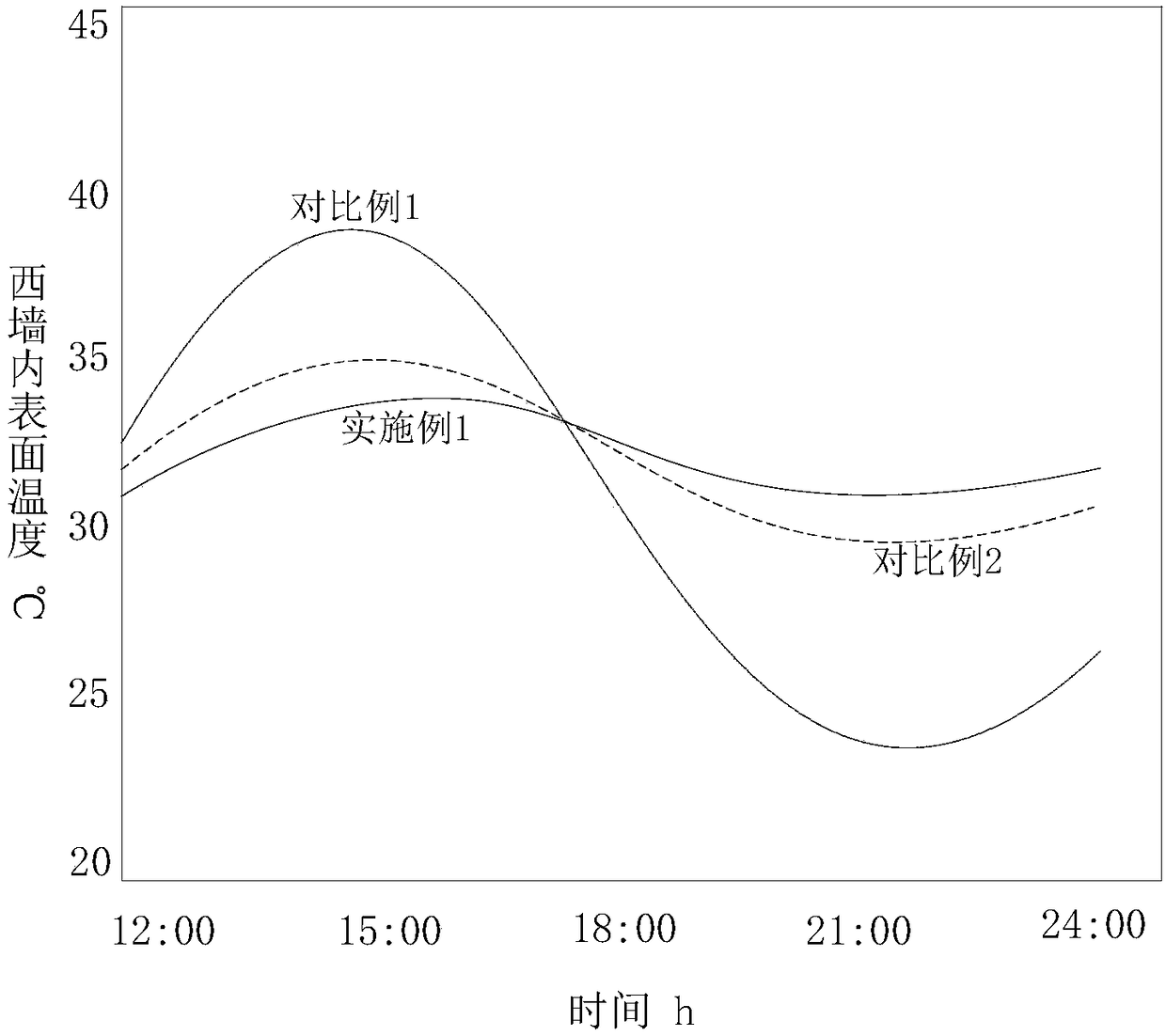

Examples

preparation example Construction

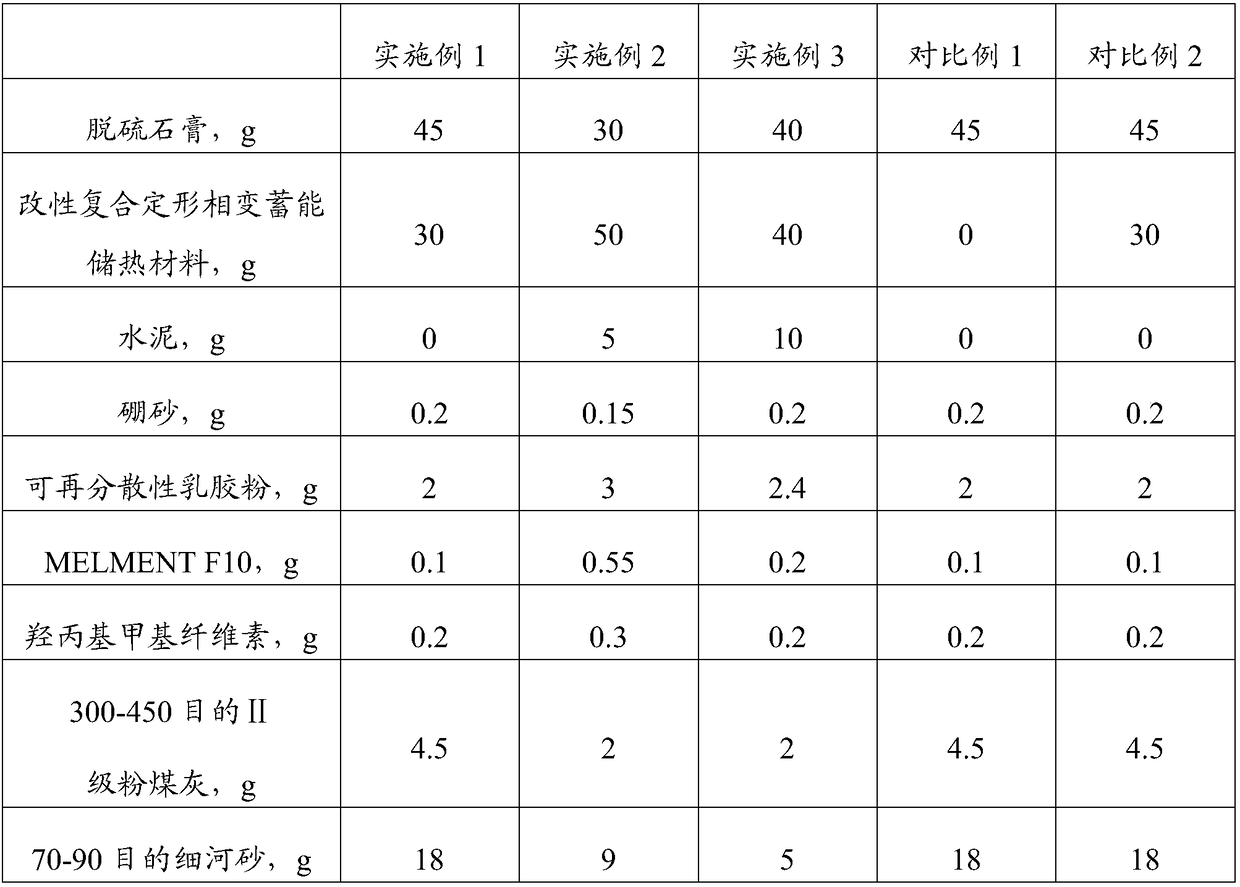

[0055] 2. Preparation of gypsum-based plastering materials

[0056] Step 1: Weigh each component according to the mass in Table 1;

[0057] Step 2: Mix desulfurized gypsum, modified composite phase change energy storage heat storage material, and retarder evenly, and put them in a constant temperature and constant pressure vacuum drying oven at a temperature of 40±2°C and a vacuum of -0.08MPa. The temperature and vacuum were vacuumized for 10 minutes;

[0058] Step 3: Blend the premixed powder obtained in step 2 with fly ash and sands of different particle sizes, and filter out 70-90 mesh fine river sand by optimizing the particle gradation of the mixture, and mix evenly;

[0059] Step 4: uniformly mix the premixed powder obtained in step 3 with cement, water reducer, latex powder, and cellulose ether to prepare the gypsum-based plastering material.

[0060] 3. Preparation of gypsum-based plastering mortar

[0061] The gypsum-based plastering material prepared above is mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com