Method for preparing superhydrophobic spherical ADN (ammonium dinitramide) based on interfacial tension

A technology of ammonium dinitramide and interfacial tension, which can be used in explosives and other directions, can solve the problems of few reports on energetic materials, and achieve the effects of mild experimental conditions, high product quality and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

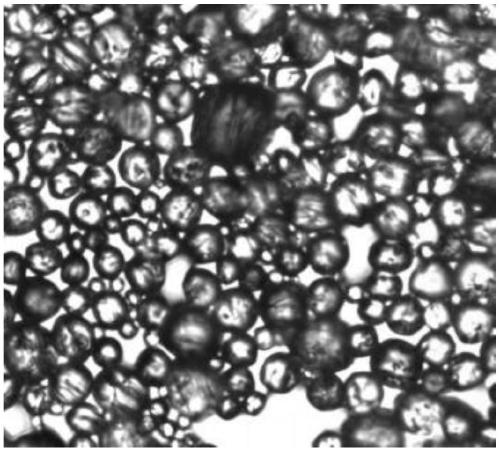

Image

Examples

Embodiment 1

[0025] A method for preparing superhydrophobic spherical dinitramide ammonium based on interfacial tension, comprising the following steps:

[0026] Step 1. Heat up 1g of ammonium dinitramide to 95°C for melting, then use electrostatic spray to spray the molten ammonium dinitramide onto 0.2g of nano-sized polyvinylidene fluoride; the injection speed of the injection pump used in the electrostatic spray is 5mL / h, the electrostatic spray voltage is 15kV, and the distance from the nozzle to nano-scale polyvinylidene fluoride is 10cm;

[0027] Step 2. After the ammonium dinitramide crystal surface is coated with a layer of polyvinylidene fluoride, the temperature is lowered to 20°C at a rate of 2°C / min to solidify and crystallize to obtain a superhydrophobic spherical ammonium dinitramide;

[0028] The hygroscopicity test (adopting GJB770A-97 standard) is carried out to the untreated ammonium dinitramide crystal and the superhydrophobic spherical ammonium dinitramide prepared, and...

Embodiment 2

[0030] A method for preparing superhydrophobic spherical dinitramide ammonium based on interfacial tension, comprising the following steps:

[0031] Step 1. Heat 1g of ammonium dinitramide to 95°C for melting, then use electrostatic spray to spray the molten ammonium dinitramide onto 0.1g of nano-sized polytetrafluoroethylene powder; the injection speed of the injection pump used in the electrostatic spray is 5mL / h, the electrostatic spray voltage is 15kV, and the distance from the nozzle to nano-scale polyvinylidene fluoride is 10cm;

[0032]Step 2: After the ammonium dinitramide crystal surface is coated with a layer of polytetrafluoroethylene, the temperature is lowered to 20°C at a rate of 5°C / min to solidify and crystallize to obtain a superhydrophobic spherical ammonium dinitramide.

[0033] The hygroscopicity test (adopting GJB770A-97 standard) is carried out to the untreated ammonium dinitramide crystal and the superhydrophobic spherical ammonium dinitramide prepared, ...

Embodiment 3

[0035] A method for preparing superhydrophobic spherical dinitramide ammonium based on interfacial tension, comprising the following steps:

[0036] Step 1. Warm up 5g ammonium dinitramide to 95°C for melting, then use electrostatic spray to spray the molten ammonium dinitramide onto 0.5g nano-sized polytetrafluoroethylene powder; the injection speed of the injection pump used in the electrostatic spray is 8mL / h, the electrostatic spray voltage is 18kV, and the distance from the nozzle to nano-scale polyvinylidene fluoride is 15cm;

[0037] Step 2: After the ammonium dinitramide crystal surface is coated with a layer of polytetrafluoroethylene, the temperature is lowered to 20°C at a rate of 5°C / min to solidify and crystallize to obtain a superhydrophobic spherical ammonium dinitramide.

[0038] The hygroscopicity test (adopting GJB770A-97 standard) is carried out to the untreated ammonium dinitramide crystal and the superhydrophobic spherical ammonium dinitramide prepared, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com