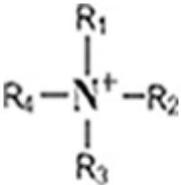

A kind of purification method of quaternary ammonium salt

A purification method and quaternary ammonium salt technology, which are applied in the purification/separation of amino compounds, organic chemistry, etc., can solve the problems of product indicators failing to reach electronic-grade standards, and achieve low processing costs, mild reaction conditions, and reduction of quaternary ammonium salts. The effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment is used to illustrate the quaternary ammonium salt purification method disclosed by the present invention, comprising the following steps:

[0057] 1) Precipitation of impurities:

[0058] Tetramethylammonium tetrafluoroborate and pure water were mixed and dissolved in a weight ratio of 1.7:1, that is, tetramethylammonium tetrafluoroborate was 200.2kg, and pure water was 120.1kg. The pure water was prepared by ion exchange resin, After dissolving, heat to 70°C, add ammonia water to adjust the pH value to 7.01, stir for 1 hour to form impurity precipitates, and control the temperature of the quaternary ammonium salt aqueous solution to 70°C to filter out the impurity precipitates, and retain the quaternary ammonium salt filtrate;

[0059] 2) Concentration of the filtrate:

[0060] The quaternary ammonium salt filtrate in step 1 was concentrated under reduced pressure at a vacuum degree of -0.085MPa and a temperature of 66°C to a saturated aqueous solutio...

Embodiment 2

[0066] This embodiment is used to illustrate the quaternary ammonium salt purification method disclosed by the present invention, comprising the following steps:

[0067] 1) Precipitation of impurities:

[0068] Tetraethylammonium hexafluorophosphate and pure water are mixed and dissolved in a weight ratio of 2.0:1, that is, tetraethylammonium hexafluorophosphate is 700.5kg, and pure water is 350.4kg. The pure water is prepared by a distiller and dissolved After heating to 73°C, add sodium hydroxide solution to adjust the pH value to 6.8, stir for 1.5 hours to form impurity precipitates, and control the temperature of the quaternary ammonium salt aqueous solution within the range of 73°C to filter out the impurity precipitates, and retain the quaternary ammonium salt filtrate;

[0069] 2) Concentration of the filtrate:

[0070] The quaternary ammonium salt filtrate in step 1 was concentrated under reduced pressure at a vacuum degree of -0.1MPa and a temperature of 59°C to a s...

Embodiment 3

[0076] This embodiment is used to illustrate the quaternary ammonium salt purification method disclosed by the present invention, comprising the following steps:

[0077] 1) Precipitation of impurities:

[0078] Tetramethylammonium hexafluorophosphate and pure water are mixed and dissolved in a weight ratio of 1.8:1, that is, tetraethylammonium hexafluorophosphate is 700.5kg, and pure water is 350.4kg. The pure water is prepared by a distiller and dissolved After heating to 72°C, add ammonia solution to adjust the pH value to 6.9, stir for 1.0 hour to form impurity precipitates, and control the temperature of the quaternary ammonium salt aqueous solution at 72°C to filter out the impurity precipitates, and retain the quaternary ammonium salt filtrate;

[0079] 2) Concentration of the filtrate:

[0080] The quaternary ammonium salt filtrate in step 1 was concentrated under reduced pressure at a vacuum degree of -0.09MPa and a temperature of 63°C to a saturated aqueous solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com