Method for preparing transition metal phosphide through chemical vapor deposition by using microwave plasmas

A chemical vapor deposition, microwave plasma technology, applied in phosphide and other directions, can solve the problems of low crystallinity, restricting catalytic performance, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

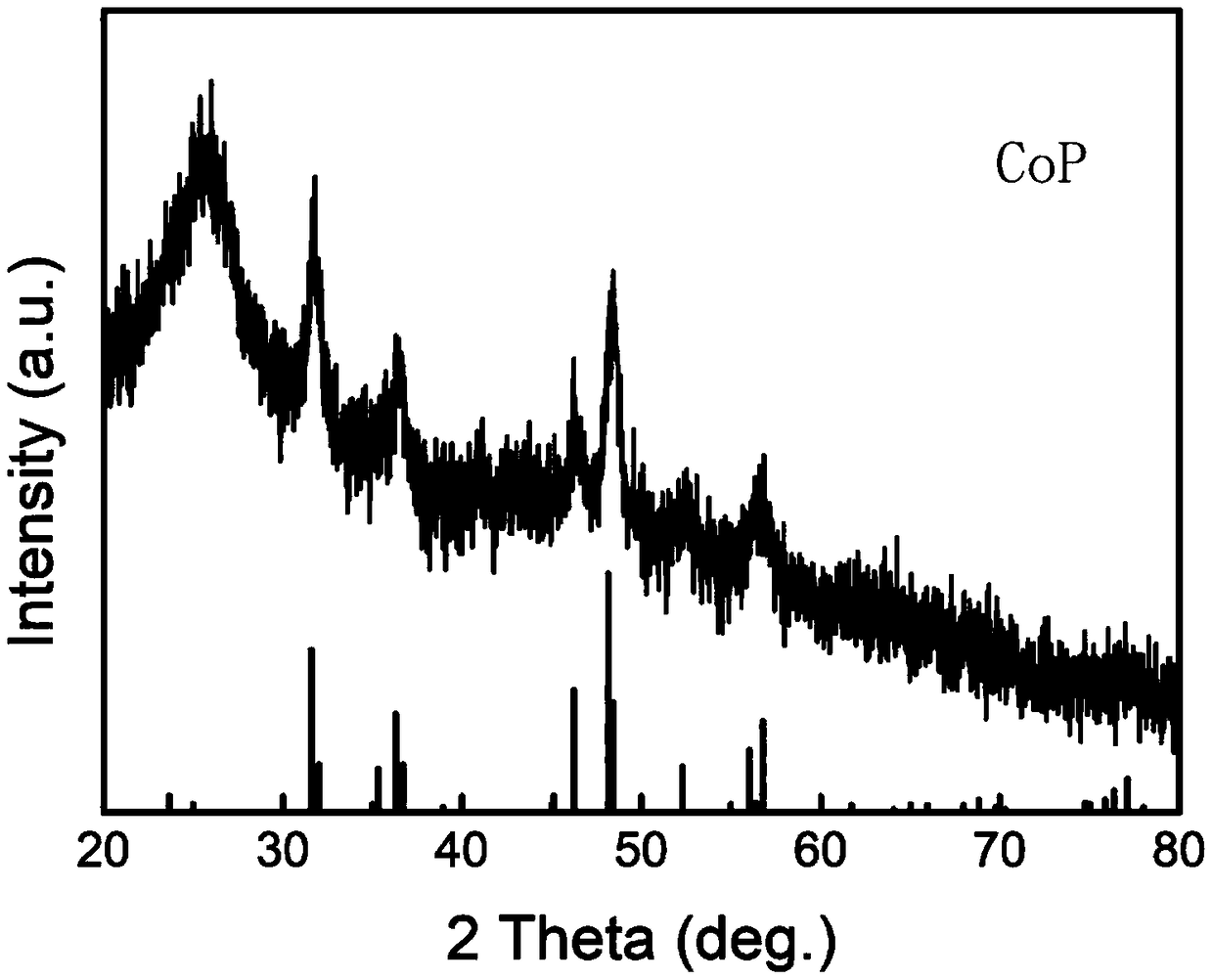

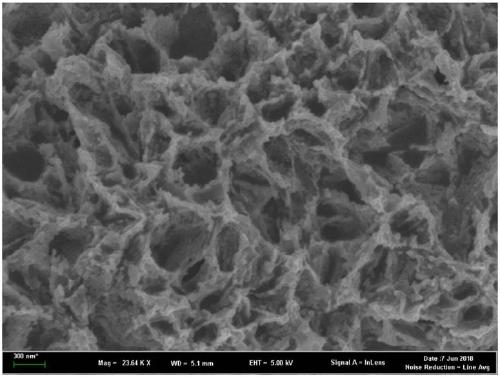

[0024] The method for preparing cobalt phosphide by microwave plasma chemical vapor deposition in this embodiment comprises the following steps:

[0025] 1) Put the ceramic boat filled with sodium hypophosphite solid and the cobalt hydroxide precursor nanosheets (grown on the carbon cloth substrate) together in the center of the graphite platform in the cavity, and vacuum the cavity to a vacuum degree of 0.5torr .

[0026] 2) Feed nitrogen gas into the cavity, and when the cavity reaches a certain pressure, adjust the microwave power, and the nitrogen gas inside the cavity absorbs microwaves to generate nitrogen plasma and phosphine plasma. Process parameters: Microwave power is 400W, working air pressure is 17torr.

[0027] 3) Adjust the flow of nitrogen gas to keep the air pressure in the chamber within a certain range, so that the plasma state is stable and wraps the sample for a period of time. Process parameters: The nitrogen flow rate is 30sccm, the chamber pressure is...

Embodiment 2

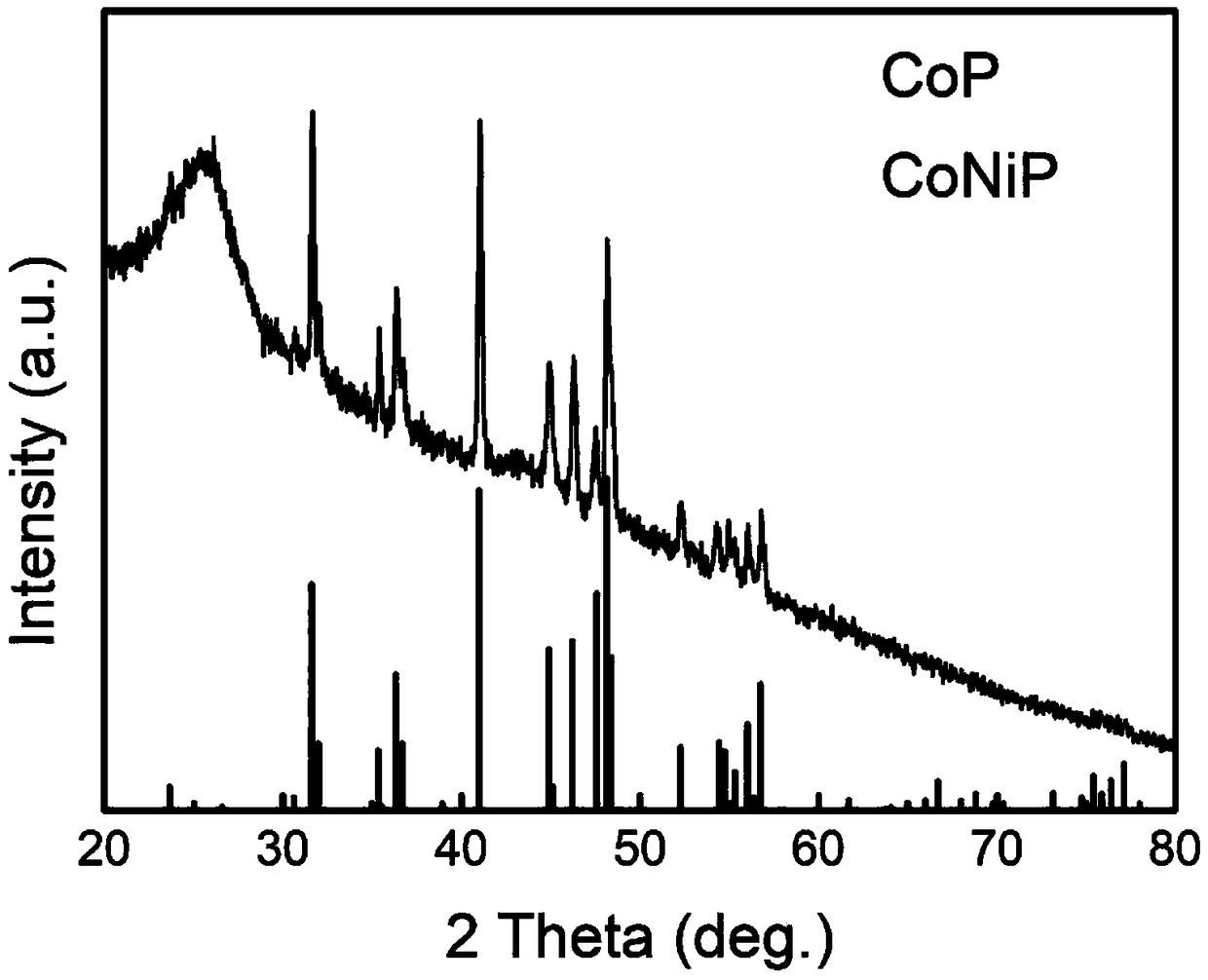

[0031] In this embodiment, the method for preparing cobalt phosphide and cobalt nickel phosphide by microwave plasma chemical vapor deposition comprises the following steps:

[0032] 1) Put the ceramic boat filled with solid sodium hypophosphite and cobalt-nickel hydroxide precursor nanosheets (grown on the carbon cloth substrate) into the center of the graphite platform in the cavity, and vacuum the cavity to a vacuum degree of 0.5 torr.

[0033] 2) Feed nitrogen gas into the cavity, and when the cavity reaches a certain pressure, adjust the microwave power, and the nitrogen gas inside the cavity absorbs microwaves to generate nitrogen plasma and phosphine plasma. Process parameters: Microwave power is 400W, working air pressure is 17torr.

[0034] 3) Adjust the flow of nitrogen gas to keep the air pressure in the chamber within a certain range, so that the plasma state is stable and wraps the sample for a period of time. Process parameters: The nitrogen flow rate is 30sccm...

Embodiment 3

[0038] The present embodiment prepares the method for iron phosphide by microwave plasma chemical vapor deposition, comprises the following steps:

[0039] 1) Put the ceramic boat filled with sodium hypophosphite and the iron hydroxide precursor nanorods (grown on the carbon cloth substrate) together in the center of the graphite platform in the cavity, and vacuum the cavity to a vacuum degree of 0.5 torr.

[0040] 2) Introduce nitrogen gas into the cavity, when the cavity reaches a certain pressure, adjust the microwave power, nitrogen and phosphine gas inside the cavity absorb microwaves to generate nitrogen plasma and phosphine plasma. Process parameters: The heating temperature is 300°C, the microwave power is 400W, and the working pressure is 17torr.

[0041] 3) Adjust the flow of nitrogen gas to keep the air pressure in the chamber within a certain range, so that the plasma state is stable and wraps the sample for a period of time. Process parameters: The nitrogen flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com