A kind of weather-resistant automobile repair varnish and preparation method thereof

An automotive and weather-resistant technology, applied in the field of coatings, can solve the problems of poor weather resistance and low adhesion, and achieve the effects of bending resistance, strong adhesion and good construction adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

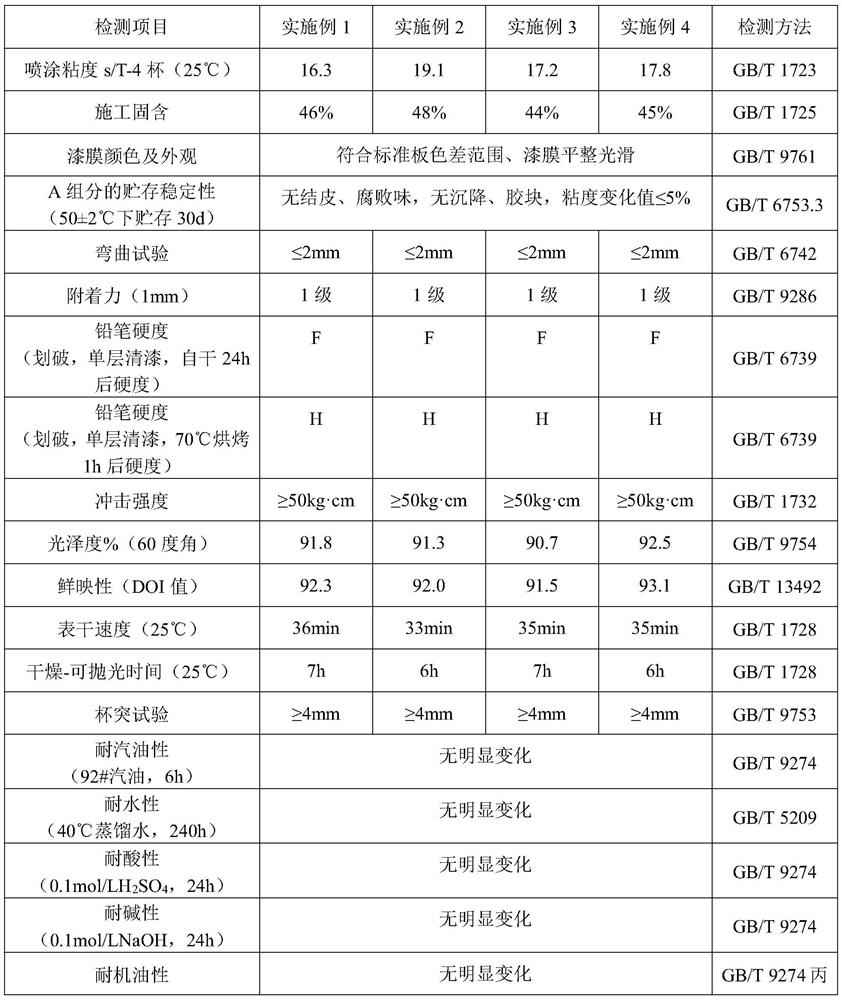

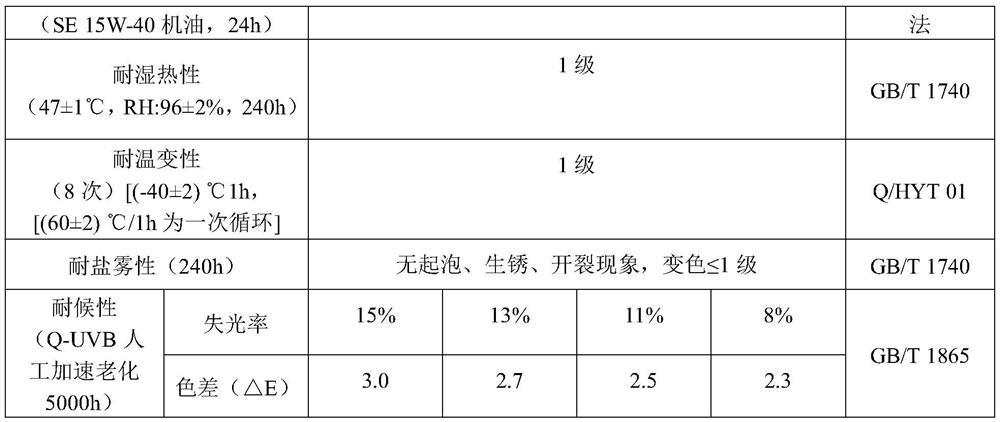

[0040] Embodiments 1-4, weather-resistant automobile repair varnish of the present invention and its preparation

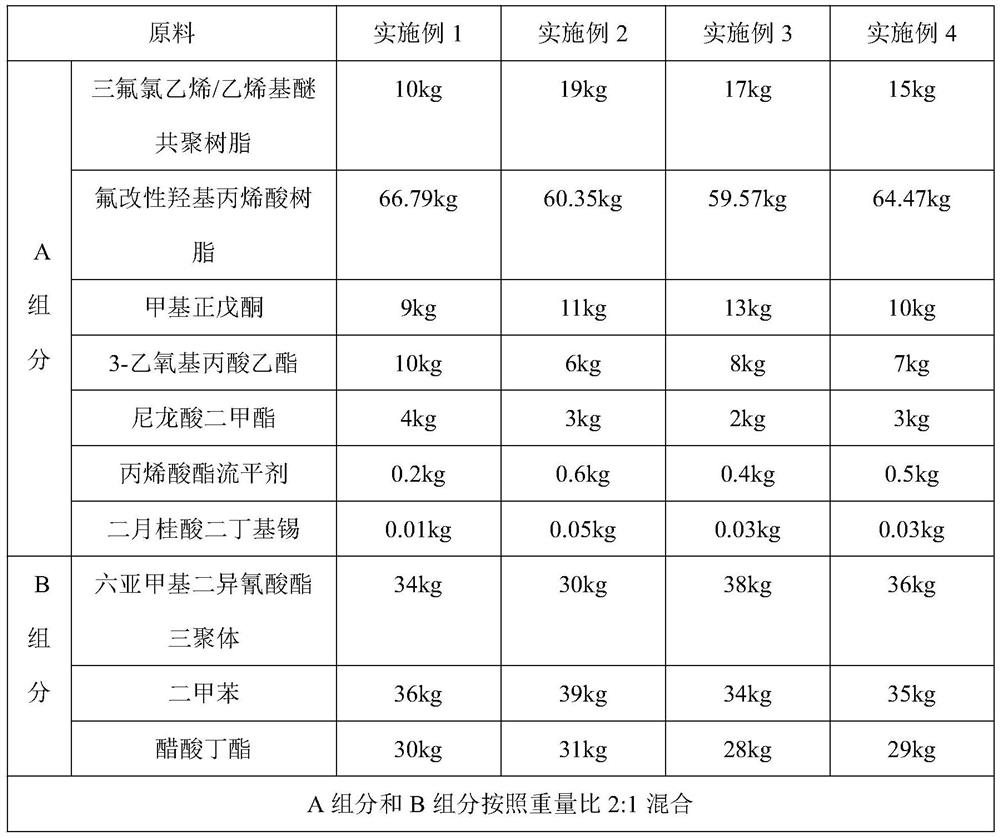

[0041] The formula of embodiment 1~4 of the present invention is as shown in table 1 below:

[0042] Table 1

[0043]

[0044] The preparation method of embodiment 1~4 of the present invention is as follows:

[0045] S1. Take methyl n-pentanone, 3-ethoxy ethyl propionate and dimethyl nylon acid and mix them to obtain solvent A, and put chlorotrifluoroethylene / vinyl ether copolymer resin and fluorine modified solvent into solvent A under stirring. Hydroxyl acrylic resin, after stirring for 2-5 minutes, add acrylate leveling agent and dibutyltin dilaurate, and stir for 10-15 minutes to obtain component A;

[0046] S2. Take xylene and butyl acetate and mix to obtain B solvent, then flush into nitrogen, add hexamethylene diisocyanate trimer under stirring, and stir for 10-15 minutes to obtain B component;

[0047] S3. Mix component A and component B according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com