Microbial preparation for degrading aflatoxin and application

A technology for aflatoxin and microbial preparation, which is applied in the field of microbial preparations for degrading aflatoxin, can solve the problems of low efficiency and different detoxification efficiency, and achieves good degradation effect, reduced aflatoxin content and good degradation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Sample Collection, Strain Isolation and Screening

[0032] 1. Sample collection time and place

[0033] On the morning of May 5, 2017, soil samples of peanut fields were collected from the experimental base of Shandong Peanut Research Institute (Wangcheng Town, Laixi City, Qingdao City).

[0034] 2. Sample processing, strain isolation and screening

[0035] Take 1 g of the collected soil sample and suspend it in 10 mL of sterile water in an ultra-clean bench, shake and dilute to prepare a soil suspension, and then dilute 100 times with sterile distilled water. Take 100 μL of the suspension and spread it on the LB solid plate, and place it at 37°C for cultivation. After 3 days, the grown colony is streaked and purified on the LB solid plate. After 3 times of streaking and purification, a strain is obtained, numbered A2025 .

Embodiment 2

[0036] Identification of embodiment 2 bacterial strain A2025

[0037] According to the method described in "Berger Bacteria Identification Handbook" (Eighth Edition), the morphological characteristics and physiological and biochemical characteristics of strain A2025 were identified, and the specific results were as follows:

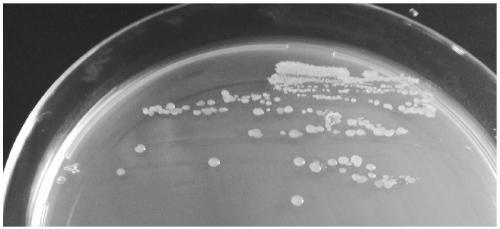

[0038] 1. Morphological characteristics: The single colony of strain A2025 is raised on LB medium, milky white, opaque ( figure 1 ), after 2 days of culture at 37°C, the colony was about 4-6mm, and wrinkles appeared on the surface of the colony after 3 days of culture.

[0039] 2. Physiological and biochemical characteristics: Oxidase activity is negative, can grow at 4-54°C, Gram staining is positive, can hydrolyze and utilize casein, gelatin and starch, but cannot utilize Tween 40 and Tween 80.

[0040] 3. 16S rRNA gene analysis

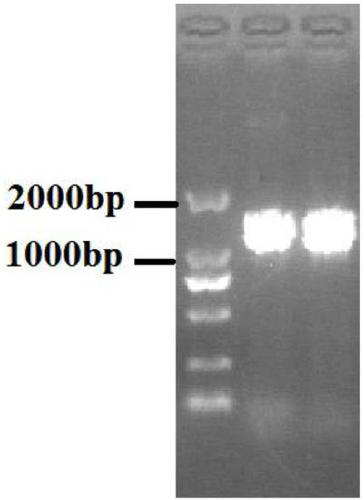

[0041] The bacterial genomic DNA of A2025 was extracted, and PCR amplification was carried out using 16S rRNA gene univers...

Embodiment 3

[0043] The cultivation of embodiment 3 Bacillus siamese A2025

[0044] The medium of Bacillus siamese A2025 is LB medium: 10g peptone, 10g sodium chloride, 5g yeast extract, 1000mL water; it can grow at 4-54°C, the optimal culture temperature is 26-37°C, and it can grow at pH 5-9 growth, the optimal pH is 7-8. It can also grow in GY medium, GY liquid medium: glucose 20g, yeast powder 5g, water 1000mL; GY solid medium: glucose 20g, yeast powder 5g, agar 20g, water 1000mL.

[0045] Take out the frozen Bacillus siamica A2025 from the refrigerator at -80°C, inoculate 50 μL of the Bacillus siamica A2025 bacterial solution into a 5 mL LB liquid medium test tube in the ultra-clean workbench, and cultivate the activated strain for 12 hours. Insert 500 μL of activated bacterial solution into 100 mL of LB liquid medium, shake and culture at 37°C for 48 hours, and the concentration of the bacterial solution is 1.6×10 8 cfu / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com