Comprehensive zinc sulfate slag recycling treatment method

A zinc sulfite, recycling technology, applied in the fields of sulfur compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of deteriorating operating environment, increasing environmental protection risks, large investment and other problems, achieving easy control, uniform and stable production capacity, The effect of uniform and stable concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

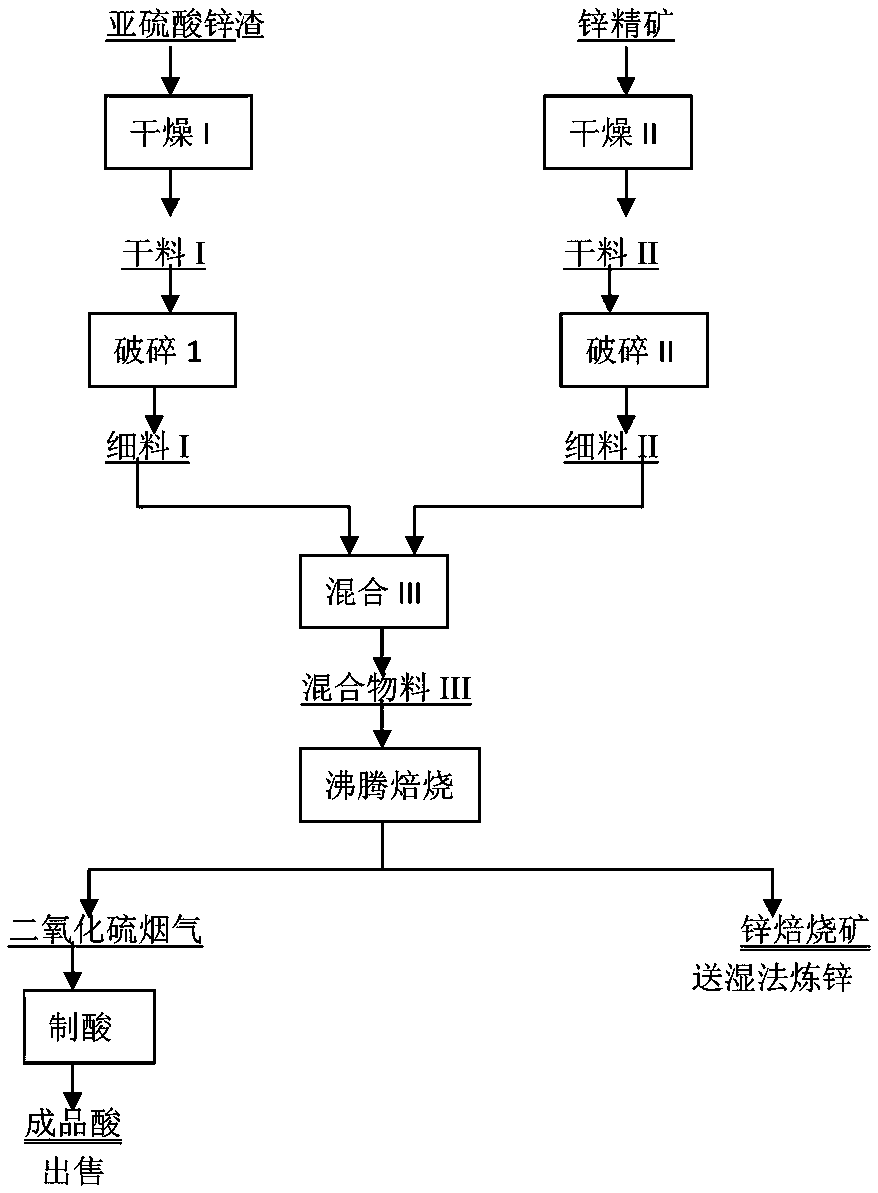

Image

Examples

Embodiment 1

[0033] Take 200 tons of zinc sulfite slag produced by our company and mix it evenly for later use, and then take 600 tons of zinc concentrate produced by our company and mix it evenly for later use; the main components of the zinc sulfite slag are 35.26wt% zinc and 10.02wt% sulfur %, lead 4.53wt%, fluorine 0.16wt%, chlorine 0.12wt%, water 28.47wt%, sulfite 96.37wt%; the main components of zinc concentrate contain zinc 45.27wt%, sulfur 30.03wt%, water 10.12 wt%, lead 1.02wt%, fluorine 0.021wt%, chlorine 0.032wt%, trace amount of sulfite.

[0034]1. Drying of zinc sulfite slag: Dry the uniformly mixed zinc sulfite slag in a drying kiln. During the drying process, the material is uniformly fed and not blocked. tons, and produce zinc sulfite dry material with a moisture content of 8-10wt%.

[0035] 2. Drying of zinc concentrate: Dry the uniformly mixed zinc concentrate in a drying kiln. During the drying process, the feeding is controlled evenly without clogging. The temperature ...

Embodiment 2

[0046] Take 350 tons of zinc sulfite slag produced by our company and mix it evenly for later use, and then take 800 tons of zinc concentrate produced by our company and mix it evenly for later use; the main components of the zinc sulfite slag are 44.92wt% zinc and 15.01wt% sulfur %, lead 5.49wt%, fluorine 0.24wt%, chlorine 0.21wt%, water 29.68wt%, sulfite 97.97wt%; the main components of zinc concentrate contain zinc 54.86wt%, sulfur 34.73wt%, water 14.96 wt%, lead 1.47wt%, fluorine 0.029wt%, chlorine 0.038wt%, trace amount of sulfite.

[0047] 1. Drying of zinc sulfite: Dry the uniformly mixed zinc sulfite slag in a drying kiln. During the drying process, the material is uniformly cut and not blocked. The temperature of the entire drying process is 100-150 °C, and the drying rate is 10-15 tons per hour. , to produce zinc sulfite dry material with a water content of 8~10wt%.

[0048] 2. Drying of zinc concentrate: Dry the uniformly mixed zinc concentrate in a drying kiln. Du...

Embodiment 3

[0059] A method for comprehensive recovery and treatment of zinc sulfite slag, comprising the following steps:

[0060] 1) Drying and crushing of zinc sulfite slag: take the zinc sulfite slag to be treated, dry and dehydrate it at 100°C so that the water content does not exceed 10wt%, and obtain a dry material of zinc sulfite slag; The zinc slag dry material is crushed, and the zinc sulfite slag fine material with a particle size of 100wt% over 60 meshes is produced for subsequent use; the main components of the zinc sulfite slag produced by absorbing sulfur dioxide flue gas are: zinc 35wt%, sulfur 10wt%, lead 4.5wt%, sulfite 96wt%, fluorine 0.15wt%, chlorine 0.1wt%, water 25wt%;

[0061] 2) Drying and crushing of zinc concentrate: Take the zinc concentrate and dry and dehydrate it at a temperature of 200°C so that the moisture contained in it does not exceed 10wt%, to obtain a dry zinc concentrate; then crush the dry zinc concentrate, The zinc concentrate fine material whose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com