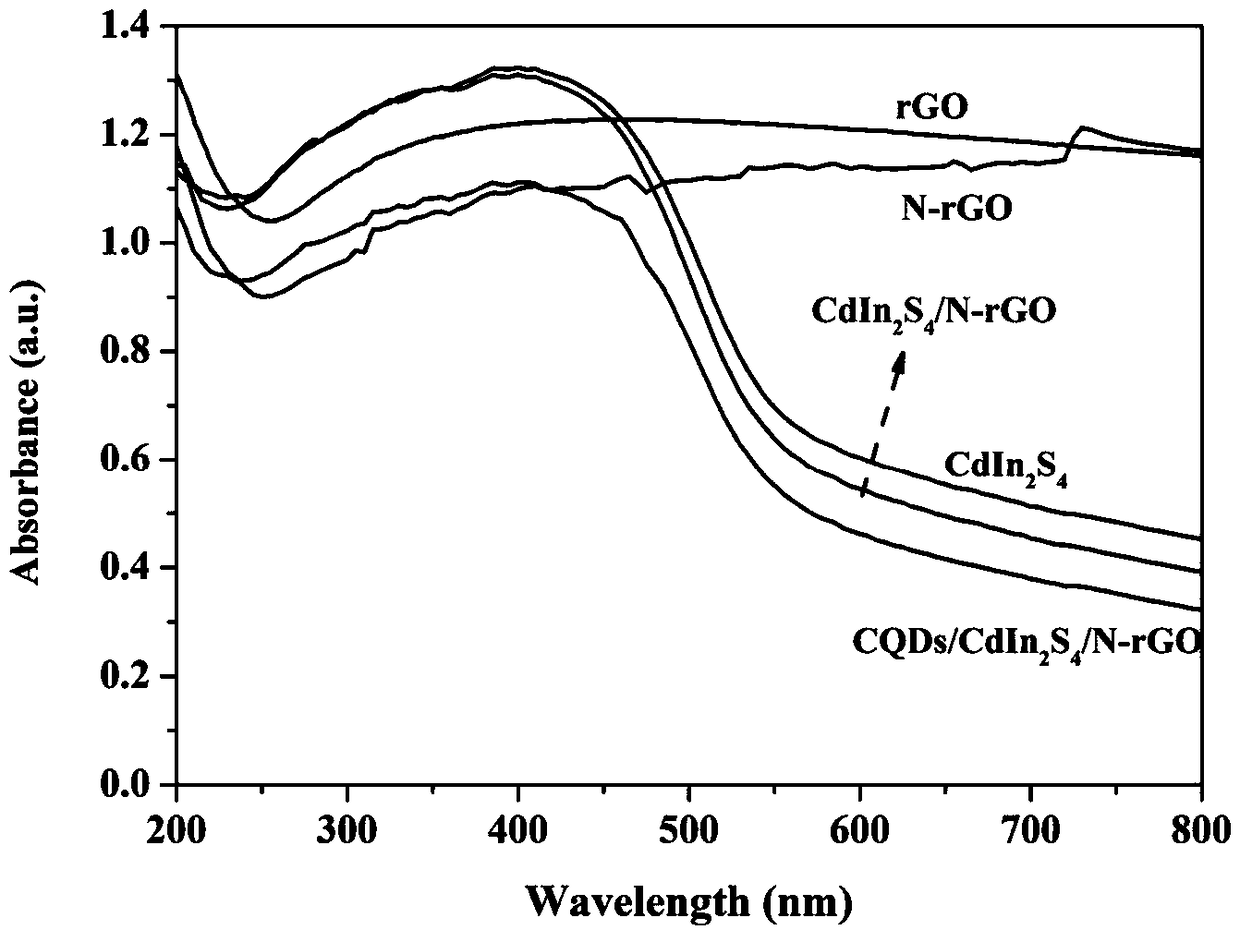

Preparation method and application of CQDs/CdIn2S4/N-rGO multi-dimensional photocatalyst

A photocatalyst, cdin2s4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as complex operation, harsh synthesis conditions, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

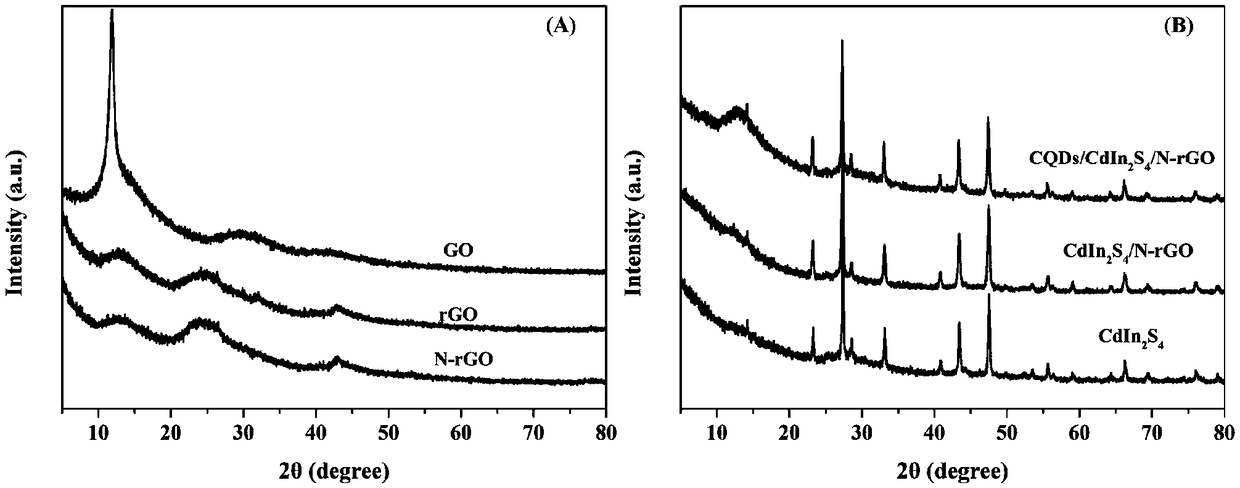

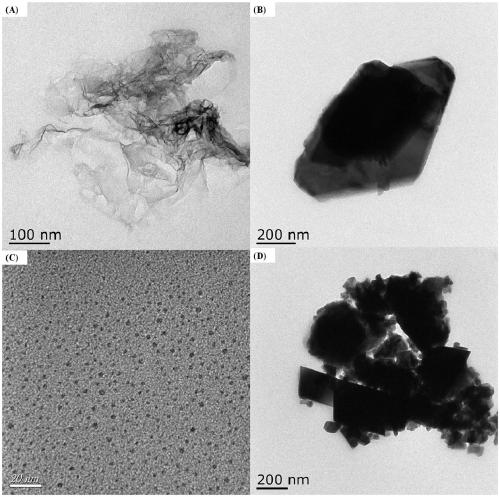

[0065] (1) Nitrogen-doped reduced graphene oxide (N-rGO):

[0066] Graphene oxide (GO) powder was synthesized by a modified Hummer method, 0.3g GO powder was added to 150mL of deionized water, and ultrasonically dispersed. Add 2mL ammonia water and sonicate. Then add 1mL hydrazine hydrate, after ultrasonic, magnetically stir at 100°C for 24h, centrifuge, wash with deionized water several times, and dry in an oven at 60°C to obtain N-rGO.

[0067] (2) Preparation of CQDs:

[0068] Weigh 1.6g vitamin C, 15mL ethylene glycol, 15mL deionized water, sonicate for 0.5h, put the kettle at 160℃ for 2h, cool to room temperature, put it in a beaker containing 380mL deionized water for 2 days, then Dilute to 400mL.

[0069] (2) CdIn 2 S 4 / N-rGO(5wt%)(The mass of N-rGO accounts for CdIn 2 S 4 5% by mass) Preparation of photocatalyst:

[0070] Weigh 0.024g N-rGO, 1mmol cadmium chloride (CdCl 2 ·2.5H 2 O), 2mmol of indium chloride (InCl 3 ·4H 2 O), 4mmol of L-cysteine, add 30mL of deionized water,...

Embodiment 2

[0075] (1) Nitrogen-doped reduced graphene oxide (N-rGO):

[0076] Graphene oxide (GO) powder was synthesized by a modified Hummer method, 0.3g GO powder was added to 150mL of deionized water, and ultrasonically dispersed. Add 2mL ammonia water and sonicate. Then 1mL hydrazine hydrate was added, followed by sonication and magnetic stirring at 100°C for 24h, centrifuged, washed with deionized water several times, and dried in an oven at 60°C to obtain N-rGO.

[0077] (2) Preparation of CQDs:

[0078] Weigh 1.6g vitamin C, 15mL ethylene glycol, 15mL deionized water, sonicate for 0.5h, put the kettle at 160℃ for 2h, cool to room temperature, put it in a beaker containing 380mL deionized water for 2 days, then Dilute to 400mL.

[0079] (2) CdIn 2 S 4 / N-rGO(5wt%)(The mass of N-rGO accounts for CdIn 2 S 4 5% by mass) Preparation of photocatalyst:

[0080] Weigh 0.024g N-rGO, 1mmol cadmium chloride (CdCl 2 ·2.5H 2 O), 2mmol of indium chloride (InCl 3 ·4H 2 O), 4mmol of L-cysteine, add 30mL...

Embodiment 3

[0085] (1) Nitrogen-doped reduced graphene oxide (N-rGO):

[0086] Graphene oxide (GO) powder was synthesized by a modified Hummer method, 0.3g GO powder was added to 150mL of deionized water, and ultrasonically dispersed. Add 2mL ammonia water and sonicate. Then add 1mL hydrazine hydrate, after ultrasonic, magnetically stir at 100°C for 24h, centrifuge, wash with deionized water several times, and dry in an oven at 60°C to obtain N-rGO.

[0087] (2) Preparation of CQDs:

[0088] Weigh 1.6g of vitamin C, 15mL of ethylene glycol, 15mL of deionized water, ultrasound for 0.5h, put the kettle at 160℃ for 2h, cool to room temperature, put it into a beaker containing 380mL of deionized water for 2 days, then Dilute to 400mL.

[0089] (2) CdIn 2 S 4 / N-rGO(5wt%)(The mass of N-rGO accounts for CdIn 2 S 4 5% by mass) Preparation of photocatalyst:

[0090] Weigh 0.024g N-rGO, 1mmol cadmium chloride (CdCl 2 ·2.5H 2 O), 2mmol of indium chloride (InCl 3 ·4H 2 O), 4mmol of L-cysteine, add 30mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com