A kind of hzsm-5/sapo-5 core-shell molecular sieve and its preparation method and application

A SAPO-5, core-shell molecular sieve technology, which is applied in the preparation and application of core-shell composite molecular sieve catalysts, achieves the effects of controlling the thickness of the shell layer, solving the agglomeration of the shell phase, and making the coating layer uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

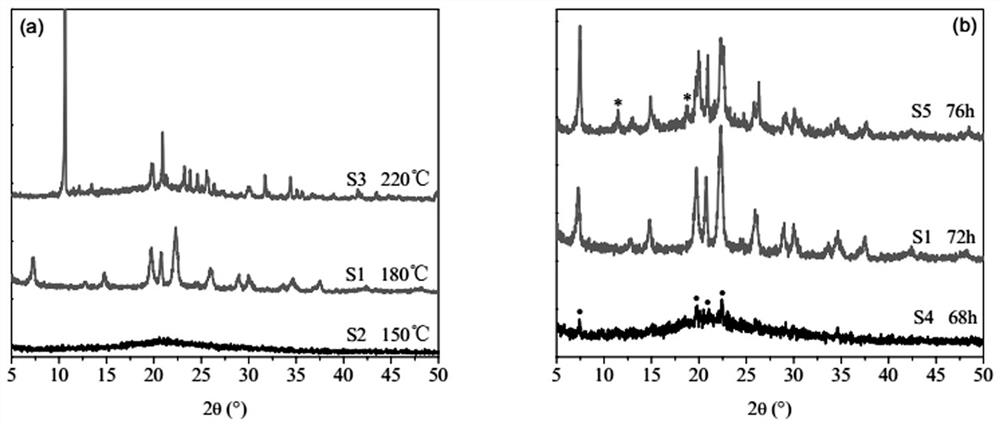

[0058] Synthesis of Nanometer SAPO-5 Molecular Sieves in Ion Thermal System

[0059] According to molar ratio 27 EM: 1.0 P 2 o 5 : 0.75 Al 2 o 3 : 0.25F - : 0.6 SiO 2 Preparation of nano-SAPO-5 synthetic sol, at this time the sol n (SiO 2 / P 2 o 5 ) = 0.6. Specifically: first place the low melting point eutectic mixture EM in an oil bath at 140°C until it is completely melted and appears uniform and transparent, then slowly add aluminum isopropoxide, H 3 PO 4 , acidic silica sol and hydrofluoric acid, after stirring for 0.5h, transfer it to a 100ml stainless steel crystallization kettle with a polytetrafluoroethylene liner, crystallize at 180°C for 72h under open conditions, and the product is quenched, ethanol and deionized Repeated washing with water, centrifugation, and drying at 80°C for 6 hours yielded a SAPO-5 molecular sieve, denoted as S1.

[0060] In this embodiment, the eutectic mixture with low melting point is formed by mixing and grinding pentaery...

Embodiment 2~9

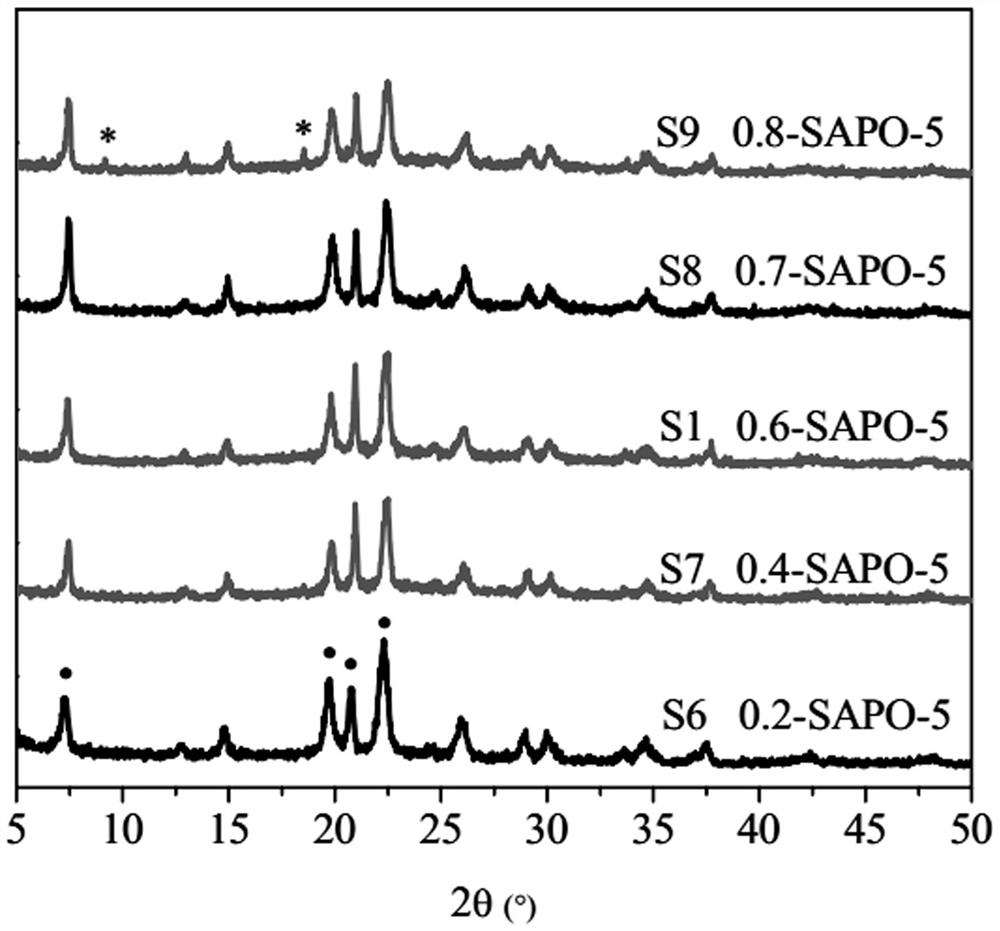

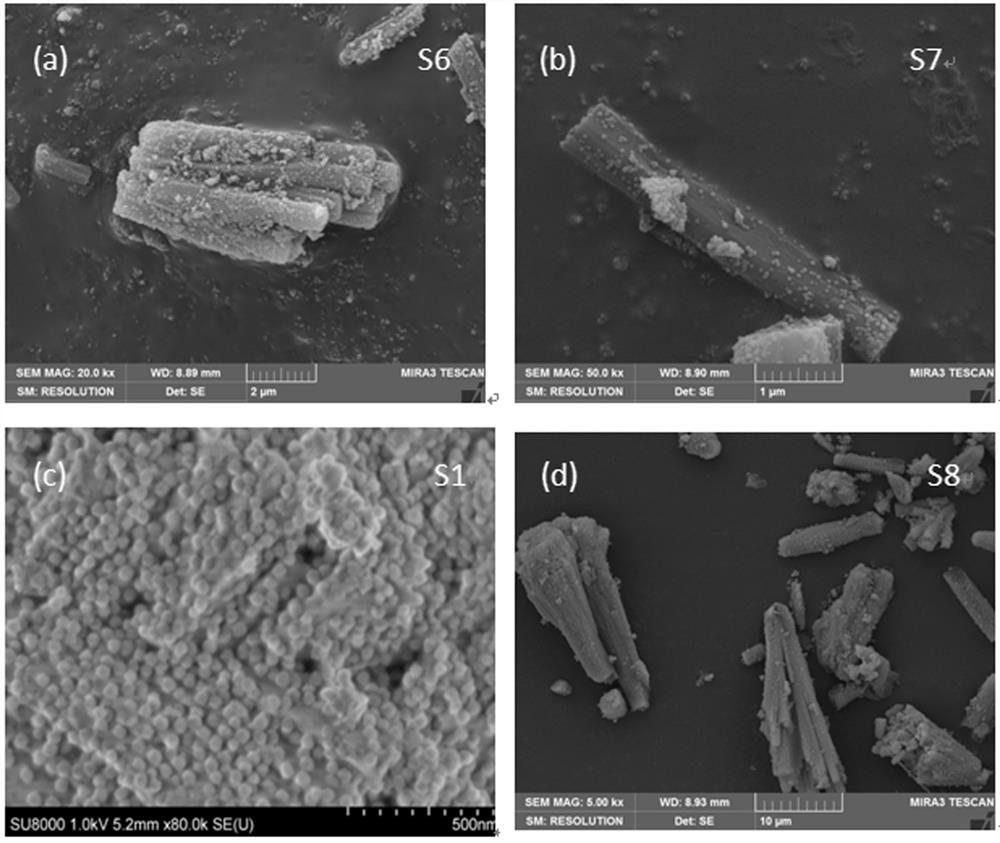

[0062] Examples 2-9 According to the method and steps of Example 1, and according to the conditions in Table 1, SAPO molecular sieves were synthesized, denoted as S2-S9.

[0063] Table 1 Preparation of SAPO molecular sieves in ion thermal system

[0064]

Embodiment 10

[0066] (1) Surface pretreatment of nuclear phase molecular sieve HZSM-5

[0067] Put HZSM-5 molecular sieve in 1 wt.%~30 wt.% cationic reagent aqueous solution according to the solid-liquid ratio of 1:100 (g / ml), stir in a water bath at 40~60°C for 40 min, quench with ice water, and filter with suction , and dried at 80°C for 8 h to obtain HZSM-5(PDDA) with a positive surface charge, which was designated as HZSM-5-Ι.

[0068] (2) HZSM-5-Ι adheres to SAPO-5 crystallites

[0069] Under the condition of 30°C water bath, put the nano-SAPO-5 molecular sieve prepared in Example 1 into the deionized water according to the mass ratio of 1:200 to the deionized water, and ultrasonically disperse for 30min to obtain a mixed solution, and then HZSM-5 -I molecular sieves are put into the mixed solution according to the mass ratio of HZSM-5 and nano-SAPO-5 as 1:3, continue to ultrasonic for 5~10min, let stand, adhere to microcrystals for 3h, wash, suction filter, dry at 100°C for 6h, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com