Composite environmental protection coating suitable for high chromium white cast iron and preparation method thereof

A technology of high-chromium white cast iron and environmental protection coating, which is applied in casting molding equipment, molds, mold components, etc., can solve the problems of low price and high production cost, and achieve low cost, reduced labor intensity and high refractoriness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

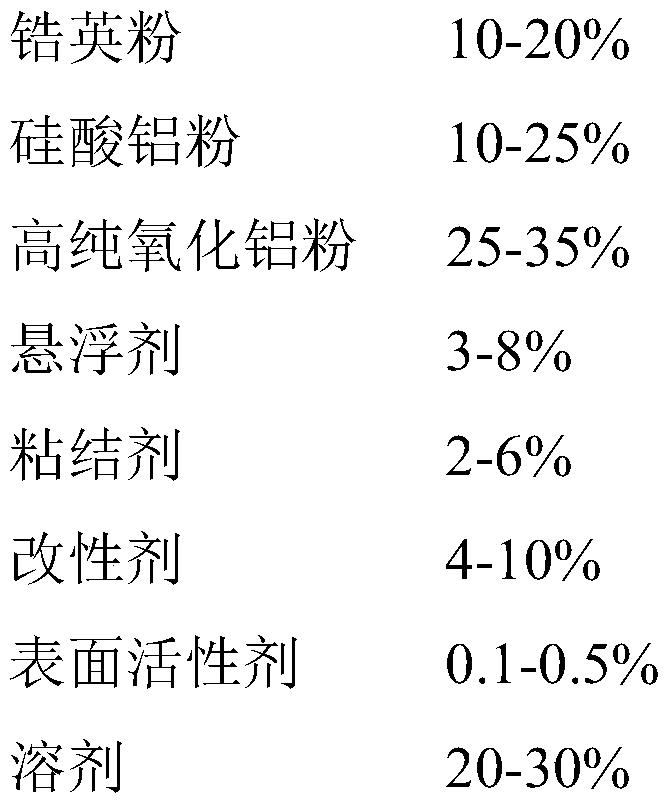

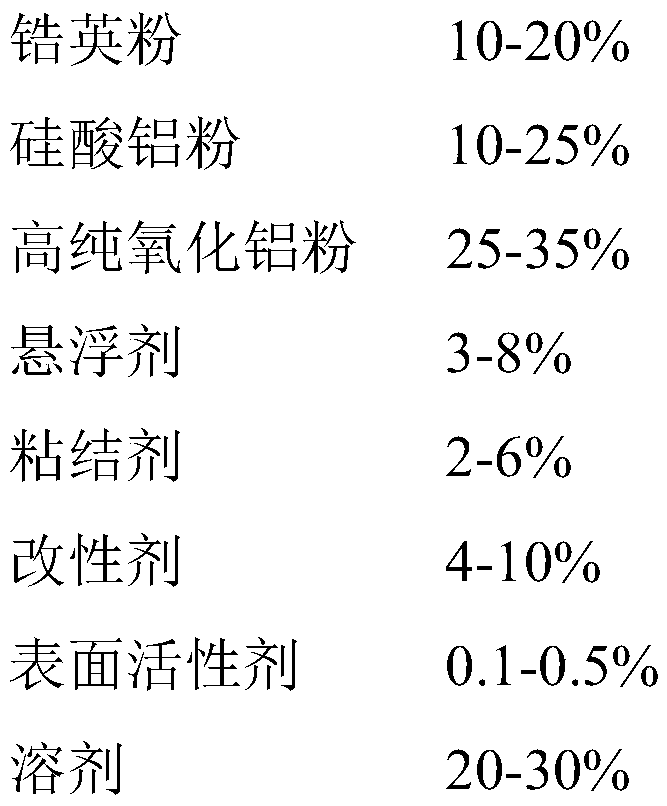

[0029] Start the reaction kettle with the high-speed disperser, drop into 200kg of ethanol first under stirring; then drop into 100kg of zircon powder (the components are: 70kg of ZrO 2 , 30 kg SiO 2 , particle size is 325 mesh), 200 kg of aluminum silicate powder (components are: 165 kg of Al 2 o 3 , 35 kg SiO 2 , the particle size is 200 mesh), 360 kg of high-purity alumina powder (the composition is: 359 kg of Al 2 o 3 , 1 kg of SiO 2 , particle size is 270 orders), 50 kilograms of sepiolite powder, 18 kilograms of first-grade wood rosin, 35 kilograms of white carbon black, 1 kilogram of cationic surfactant, open high-speed disperser and stir for half an hour; Add 50 kilograms of ethanol at last, After the Baume degree is adjusted to be greater than 90゜Bé, the coating preparation is completed.

Embodiment 2

[0031] Start the reaction kettle with the high-speed disperser, and drop into 190kg of ethanol under stirring; then drop into 135kg of zircon powder (the components are: 90kg of ZrO 2 , 45 kg SiO 2 , particle size is 325 mesh), 170 kg of aluminum silicate powder (components are: 140 kg of Al 2 o 3 , 60 kg SiO 2 , particle size is 200 mesh), 375 kg of high-purity alumina powder (component: 373.5 kg of Al 2 o 3 , 1.5 kg SiO2 2 , particle size is 270 orders), 45 kilograms of sepiolite powder, 18 kilograms of first-grade wood rosin, 35 kilograms of white carbon black, 1 kilogram of cationic surfactant, open high-speed disperser and stir for half an hour; Add 50 kilograms of ethanol at last, After the Baume degree is adjusted to be greater than 90゜Bé, the coating preparation is completed.

Embodiment 3

[0033] Start the reaction kettle with the high-speed disperser, drop into 200kg of ethanol first under stirring; 2 , 40 kg SiO 2 , particle size is 325 mesh), 180 kg of aluminum silicate powder (components are: 145 kg of Al 2 o 3 , 35 kg SiO 2 , particle size is 200 mesh), 370 kg of high-purity alumina powder (component: 369 kg of Al 2 o 3 , 1 kg of SiO 2 , particle size is 270 orders), 42 kilograms of sepiolite powder, 19 kilograms of first-grade wood rosin, 38 kilograms of white carbon black, 1 kilogram of cationic surfactant, open high-speed disperser and stir for half an hour; Add 50 kilograms of ethanol at last, After the Baume degree is adjusted to be greater than 90゜Bé, the coating preparation is completed.

[0034] The coating that each embodiment obtains is tested, obtains data as following table.

[0035] Exterior Density (g / cm 3 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com