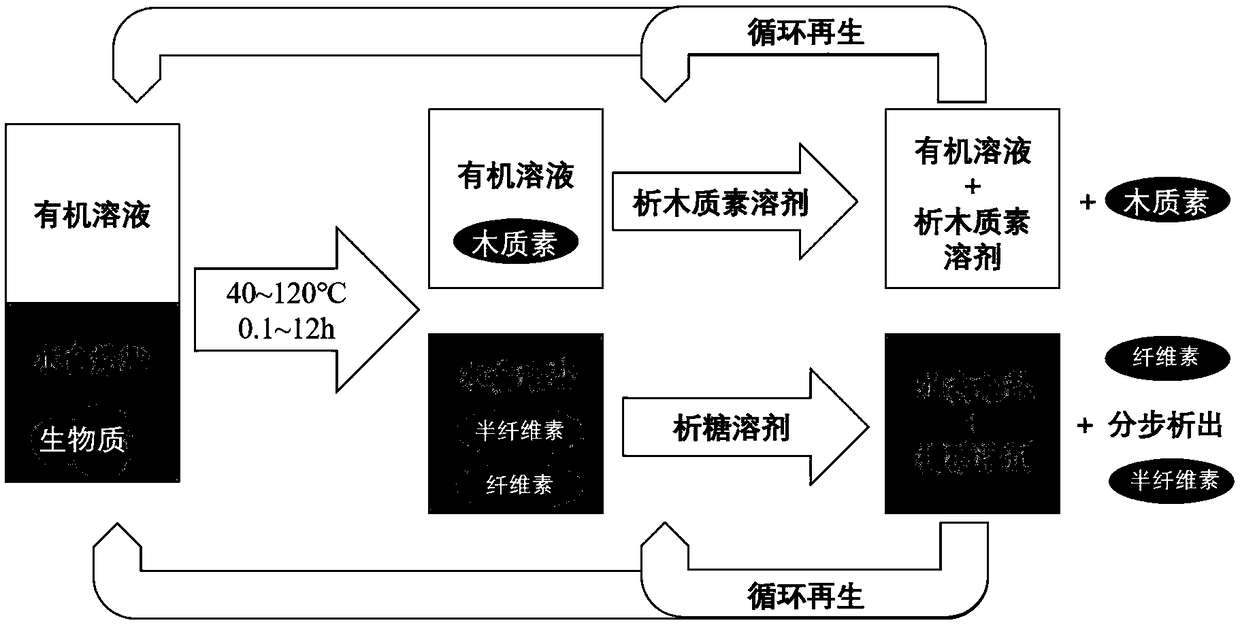

Method for fractionation of lignocelluloses biomass components through two-phase fused salt system

A lignocellulosic and fractional separation technology, which is applied in fiber raw material processing, textiles and papermaking, etc., can solve problems such as difficult solvent circulation, high reaction temperature, and high environmental pressure, so as to reduce energy consumption, simplify the process flow, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Using 5g of Pennisetum with a particle size of 0.5mm (containing 32% cellulose, 22% hemicellulose, and 28% lignin) as raw material, according to the mass volume ratio of raw material and hydrated molten salt 1g: 5cm 3 The amount of ZnCl added 2 ·3H 2 O hydrate molten salt 25cm 3 , and add 25cm 3 Furfural forms a two-phase molten salt-organic solution fractionation system for lignocellulosic biomass components. After stirring and reacting at 80° C. for 2 h, the residue was filtered, and the hydrated molten salt phase in which hemicellulose and cellulose were dissolved and the organic solution phase in which lignin was dissolved were separated.

[0031] With acetone as the organic solvent for sugar analysis, add acetone of 0.05 times the volume of the hydrated molten salt phase in the hydrated molten salt phase that is dissolved with hemicellulose and cellulose, and filter the obtained filter residue after drying to obtain 0.33g of the cellulose component. The mass co...

Embodiment 2

[0034] Using 5g of Pennisetum with a particle size of 0.5mm (containing 32% cellulose, 22% hemicellulose, and 28% lignin) as raw material, according to the mass volume ratio of raw material and hydrated molten salt 1g: 10cm 3 The amount of LiBr·3H added 2 O hydrate molten salt 50cm 3 , and add 100cm 3 Ethylene glycol phenyl ether forms a two-phase molten salt-organic solution fractionation system for lignocellulosic biomass components. After stirring and reacting at 100° C. for 1 h, the residue was filtered, and the hydrated molten salt phase in which hemicellulose and cellulose were dissolved and the organic solution phase in which lignin was dissolved were separated.

[0035] Using ethanol as the organic solvent for sugar analysis, add ethanol with 0.5 times the volume of the hydrated molten salt phase in the hydrated molten salt phase dissolved with hemicellulose and cellulose, and obtain 2.28g of the cellulose component after the filter residue obtained by filtering is dri...

Embodiment 3

[0038] Using 5g of bagasse (containing 38% cellulose, 27% hemicellulose, and 18% lignin) with a particle size of 0.5mm as raw material, according to the mass volume ratio of raw material and hydrated molten salt 1g: 10cm 3 The amount of ZnCl added 2 2H 2 O hydrate molten salt 50cm 3 , and add 10cm 3 Ethylene glycol phenyl ether-toluene solution with a volume ratio of 1:1 forms a two-phase molten salt-organic solution fractionation system for lignocellulosic biomass components. After stirring and reacting at 120° C. for 0.1 h, the residue was filtered, and the hydrated molten salt phase in which hemicellulose and cellulose were dissolved and the organic solution phase in which lignin was dissolved were separated.

[0039] Using methanol as an organic solvent for sugar analysis, add methanol with a volume of 0.2 times the volume of the hydrated molten salt phase in the hydrated molten salt phase in which hemicellulose and cellulose are dissolved, filter, and dry the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com