A preparation method and application of a flower-like FeSx/C nano composite material

A nano-composite, flower-like technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of electrode material falling off, active material structure collapse, loss of electrochemical activity, etc. The effect of low cost, little environmental pollution and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Select iron and sulfur according to the molar ratio of 1:2.5, and the dopamine content is 30%.

[0027] Dissolve 0.5012g of ferric chloride hexahydrate, 0.3521g of thiourea, 0.12g of dopamine and 0.06g of potassium persulfate in 20mL of hydrochloric acid solution with pH=4, and ultrasonicate for 30min at a power of 99W to obtain a clear and transparent mixed solution A;

[0028] 2) Pour the mixed solution A in step (1) into the reaction kettle, and react at 200°C for 60h;

[0029] 3) The obtained product was washed three times with deionized water and absolute ethanol respectively, and the synthetic material was dried in a blast drying oven at 80°C for 12 hours, and then dried in a tube furnace at 2°C·min -1 The heating rate reached 600°C and kept for 2h, and finally the product in the crucible was collected to obtain FeS x / C nanocomposite sodium ion battery anode material.

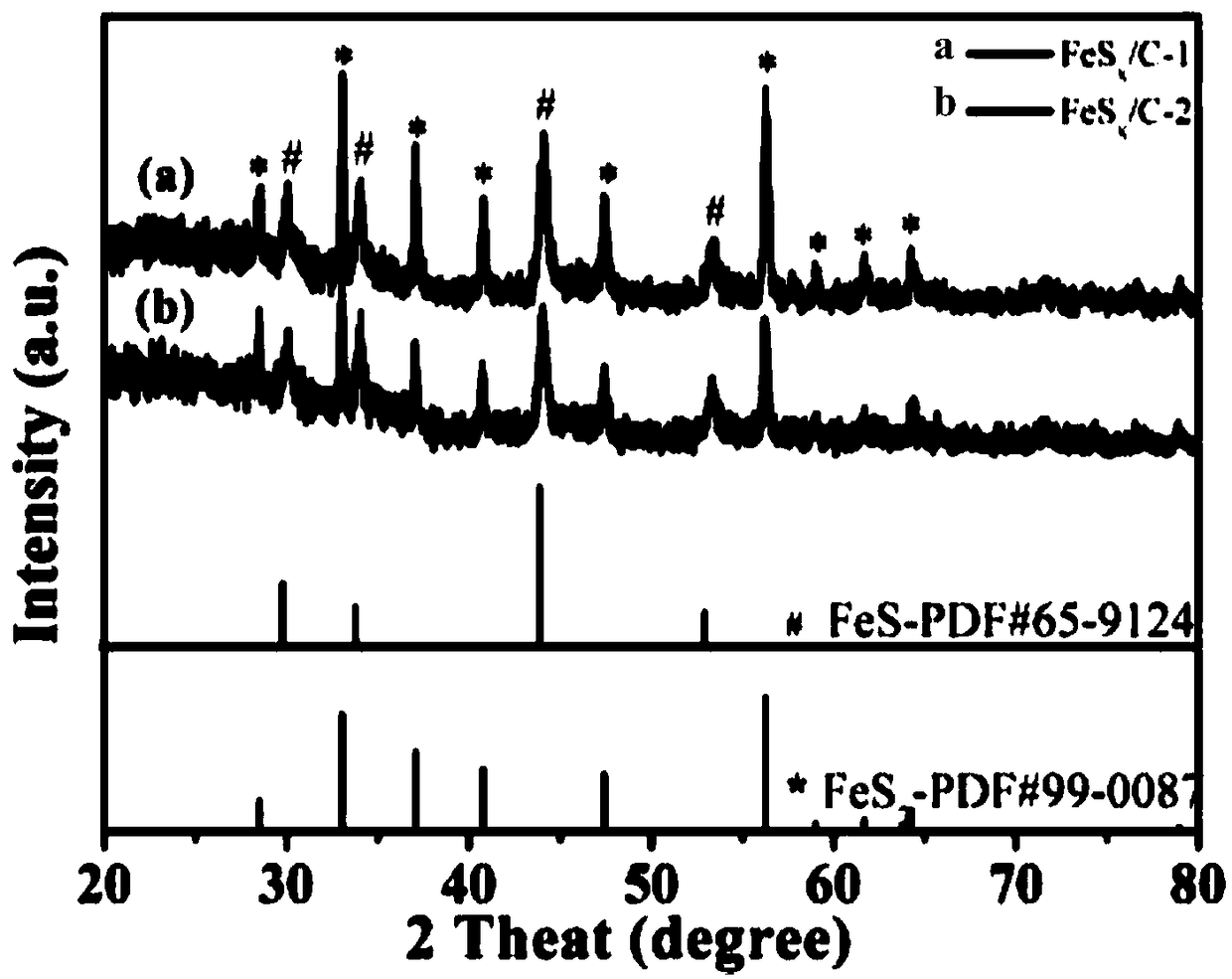

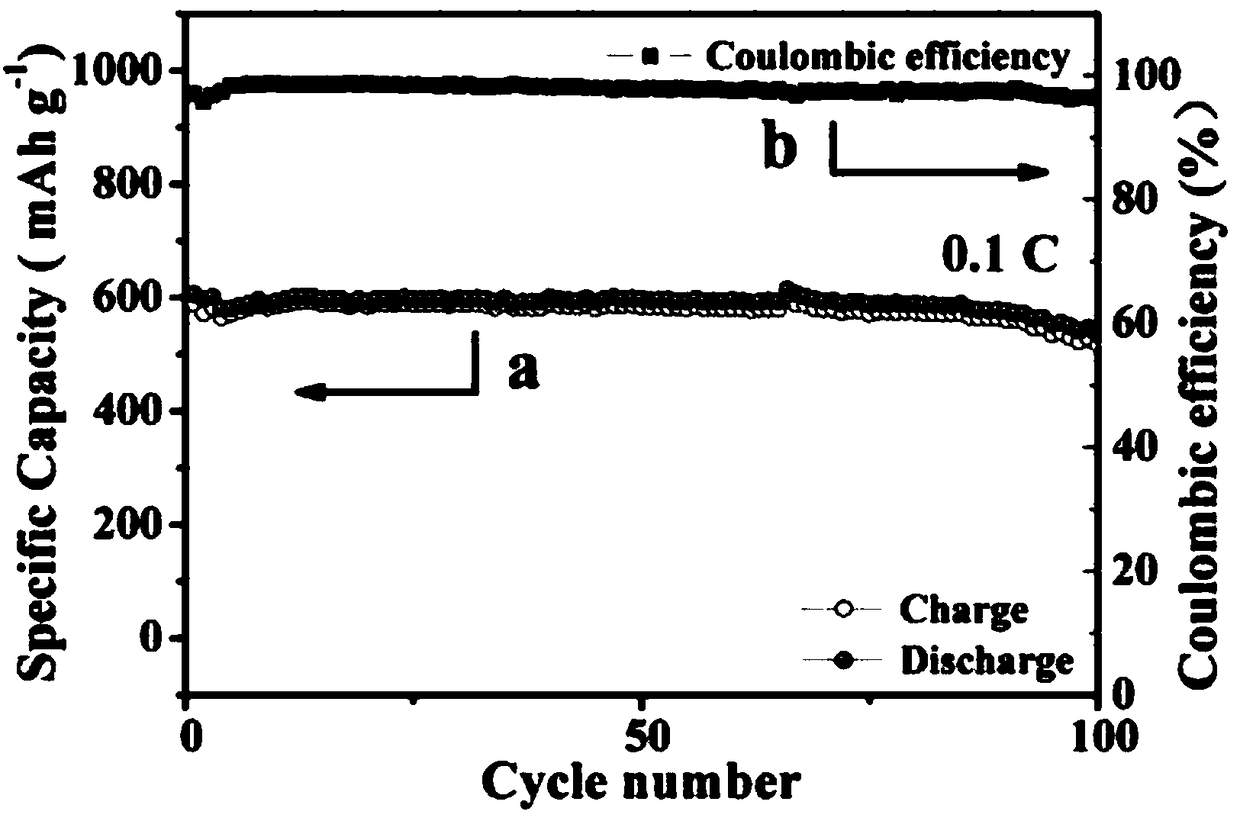

[0030] figure 1 Among (a) is the FeS prepared in the embodiment case 1 x / C nanocomposi...

Embodiment 2

[0036] 1) Select iron and sulfur according to the molar ratio of 1:2.5, and the dopamine content is 20% of the conditions,

[0037] Dissolve 0.5002g of ferric chloride hexahydrate, 0.3541g of thiourea and 0.06g of dopamine in 20mL of hydrochloric acid solution with pH=4.0, add 0.03g of potassium persulfate, ultrasonicate for 30min, and the ultrasonic power is 99W, to obtain a clear and transparent mixed solution A ;

[0038] 2) Pour the mixed solution A in step (1) into the reaction kettle, and react at 200°C for 60h;

[0039] 3) The obtained product was washed three times with deionized water and absolute ethanol respectively, and the synthetic material was dried in a blast drying oven at 80°C for 12 hours, and then dried in a tube furnace at 2°C·min -1 The heating rate reached 600°C and kept for 2h, and finally the product in the crucible was collected to obtain FeS x / C nanocomposite sodium ion battery anode material.

[0040] figure 1 Among (b) is the FeS prepared in the...

Embodiment 3

[0042] 1) Select iron and sulfur according to the molar ratio of 1:2.5, and the dopamine content is 30%. Take 0.5002g of ferric chloride hexahydrate, 0.3541g of thiourea and 0.12g of dopamine and dissolve them in 20mL of trishydroxymethylamino with pH=8.5 In methane solution, ultrasonic 30min, ultrasonic power 99W, to obtain a clear and transparent mixed solution A;

[0043] 2) Pour the mixed solution A in step (1) into the reaction kettle, and react at 200°C for 60h;

[0044] 3) The obtained product was washed three times with deionized water and absolute ethanol respectively, and the synthetic material was dried in a blast drying oven at 80°C for 12 hours, and then dried in a tube furnace at 2°C·min -1 The heating rate reaches 400°C and is maintained for 2h, and finally the product in the crucible is collected to obtain FeS x / C nanocomposite sodium ion battery anode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com