Compound type feed for dairy cattle and preparation method thereof

A dairy cow feed and compound technology, which is applied in the direction of animal feed, animal feed, and animal feed molding or processing, can solve the problems of unstable adsorption of medical stone, difficult to mix the feed evenly, and affect the feed preparation, etc., to improve the activity. and feed utilization, improving milk quality, increasing umami and palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

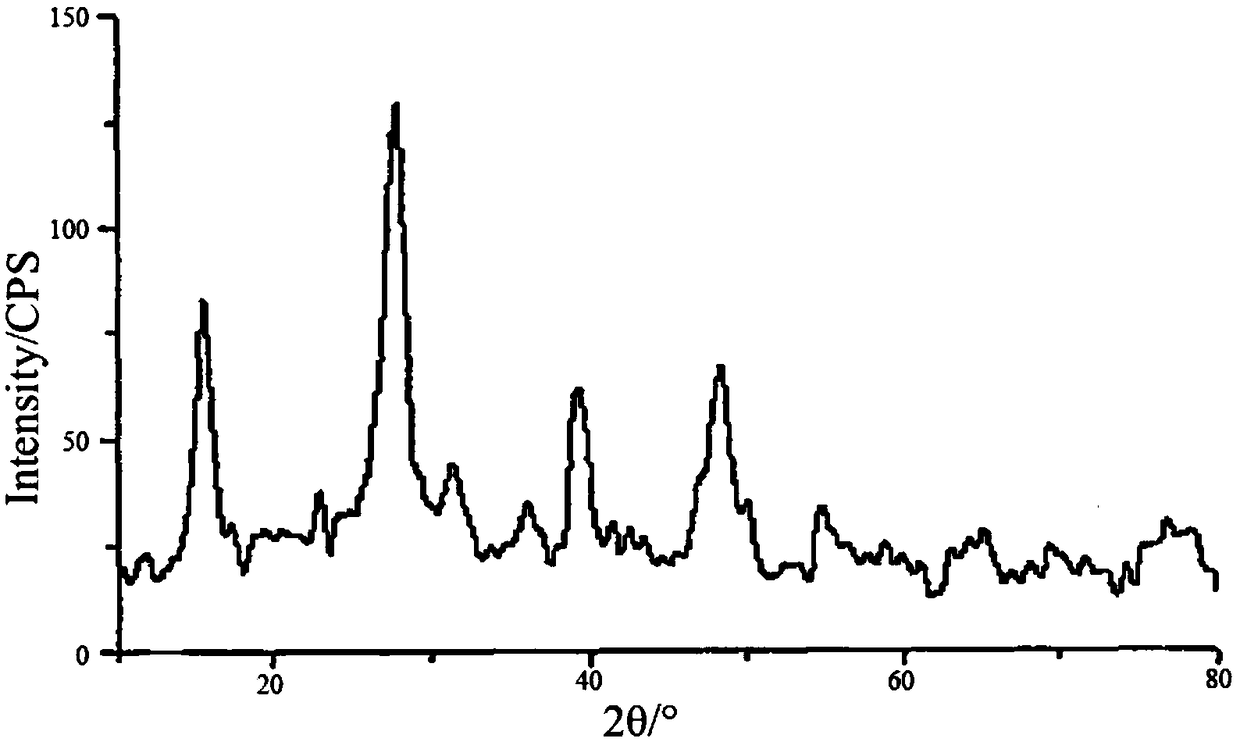

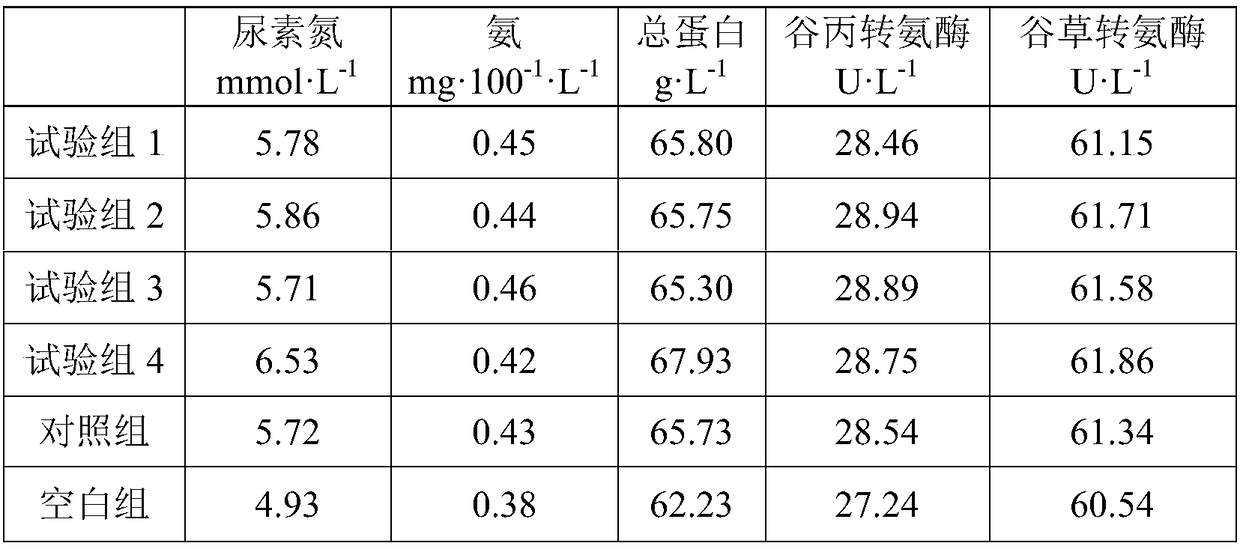

[0034] A composite dairy cow feed, the feed includes lanthanum oxide nanoparticles, and the average particle diameter of the nanoparticles is 18 nm. Nanoparticles have better particle flow performance and dispersion performance, do not agglomerate, and the absorption utilization rate and biological activity of nanoparticles are higher, which can improve the rumen microflora of ruminants and maintain a stable acidic environment in the rumen. The ratio of various microorganisms can reach Ideally, it can promote the effective utilization of nutrients in the rumen to activate growth factors in animals, increase the activity of digestive enzymes in the animal body and feed utilization, improve animal gastrointestinal functions, and increase milk production and milk quality in dairy cows. It has the function of promoting digestion and absorption, sterilization and detoxification.

[0035] The preparation steps of sodium oxide nanoparticles are as follows: take the prepared precursor la...

Embodiment 2

[0049] A composite dairy cow feed, the feed includes lanthanum oxide nanoparticles, the average particle size of the nanoparticles is 20nm, the raw materials and weight parts of the feed are as follows: 12 parts of corn germ, 7 parts of beer yeast powder, 7 parts of wheat Parts, 10 parts of alfalfa, 4 parts of calcium dihydrogen phosphate, 13 parts of puffed mixed meal, 4 parts of rumen-protected methionine, 4 parts of rumen-protected lysine, and 3 parts of lanthanum oxide nanoparticles.

[0050] The method for preparing the above compound dairy cow feed includes the following steps:

[0051] 1) Preparation of the precursor lanthanum oxalate: grind lanthanum chloride and sodium oxalate separately and mix them thoroughly. The molar ratio of lanthanum chloride and sodium oxalate is 2.5:3, and then grind together for 45 minutes, and then add hot water to form a suspension , Suction filtration 2 times, and then rinsed with absolute ethanol 2 times, the filter cake is dried at 85°C to o...

Embodiment 3

[0058] A composite dairy cow feed, the feed includes lanthanum oxide nanoparticles, the average particle size of the nanoparticles is 22nm, the raw materials of the feed and their weight parts are as follows: 14 parts of corn germ, 8 parts of beer yeast powder, 8 parts of wheat Parts, 11 parts of alfalco, 3.5 parts of calcium dihydrogen phosphate, 14 parts of puffed meal, 4 parts of rumen-protected methionine, 4 parts of rumen-protected lysine, 4 parts of lanthanum oxide nanoparticles.

[0059] The method for preparing the above compound dairy cow feed includes the following steps:

[0060] 1) Preparation of the precursor lanthanum oxalate: grind lanthanum chloride and sodium oxalate separately, and mix them thoroughly. The molar ratio of lanthanum chloride and sodium oxalate is 2.5:3, and then grind together for 48 minutes, and then add hot water to form a suspension , Suction filtration 3 times, and then rinsed with absolute ethanol 2 times, the filter cake is dried at 90°C to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com