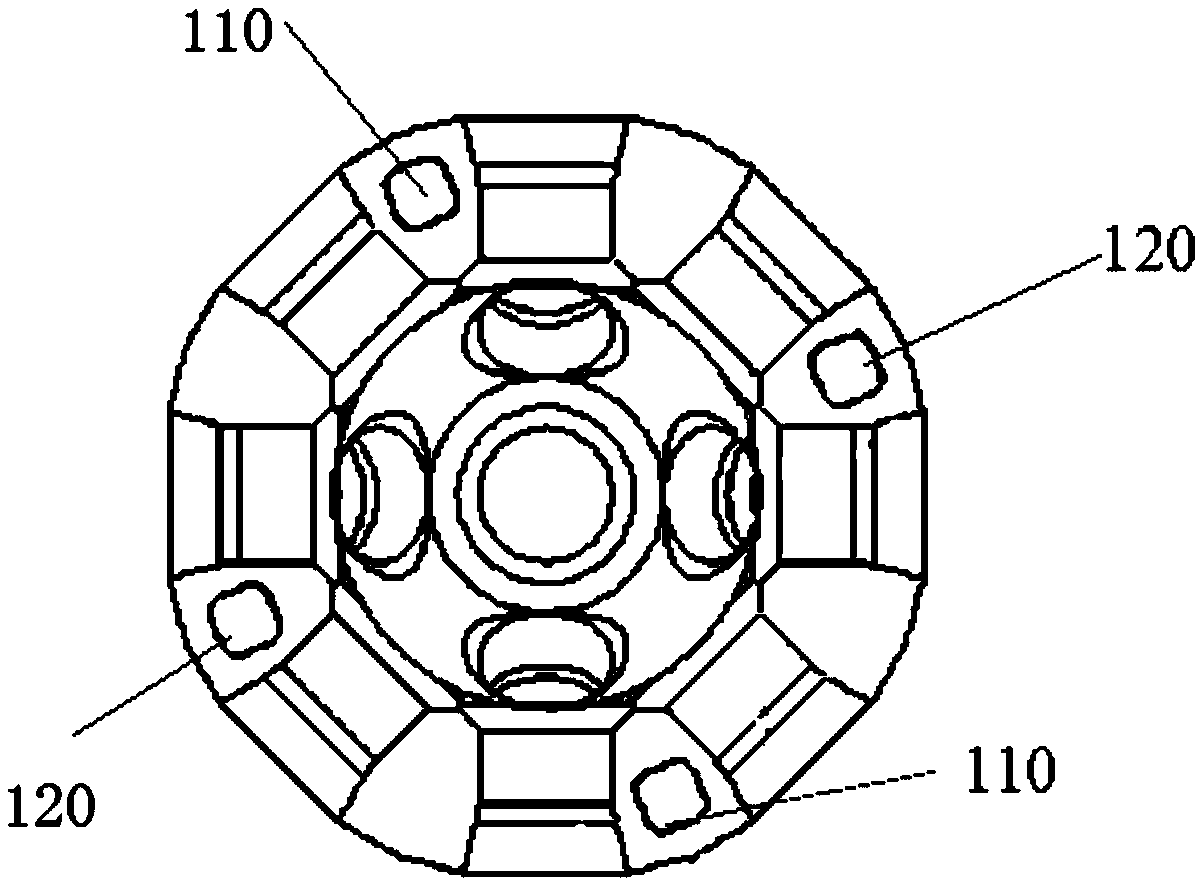

Titanium alloy hollow node ball and preparation method thereof

A node ball, titanium alloy technology, applied in the field of powder metallurgy, can solve the problems of difficult removal of internal materials, poor machining performance, low production efficiency, etc., to achieve the effect of good consistency, low equipment requirements, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

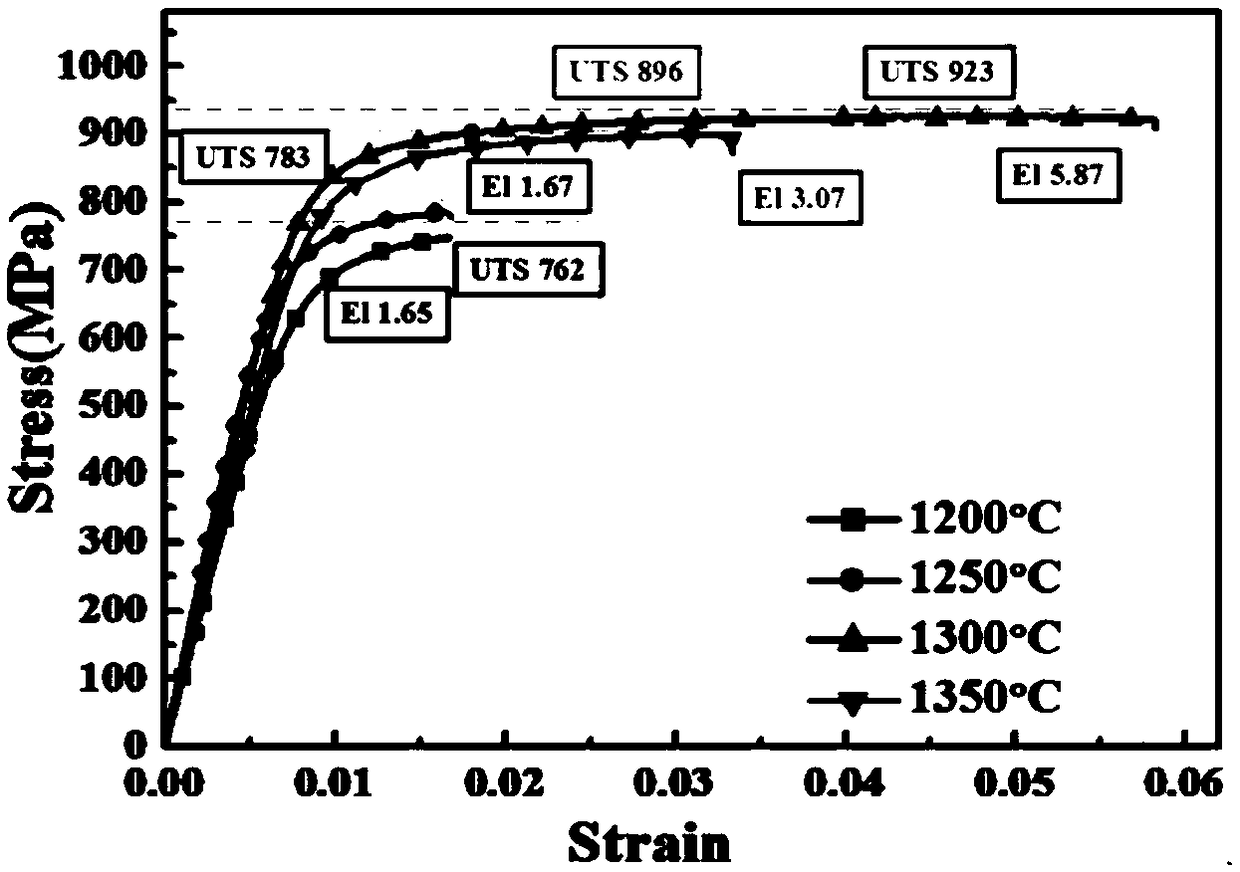

Embodiment 1

[0042] The raw material is TC4 powder mixed with 50% hydrogenated dehydrogenation powder and atomized powder, the median particle size is 27.2 μm, mixed with a plastic-based binder, the binder includes 85wt.% polyoxymethylene, 5wt.% high-density polyethylene , 5wt.% polypropylene, 3wt.% microcrystalline wax and 2wt.% stearic acid. The mixing temperature is 180°C, and the time is 1.5 hours. After the mixing is completed and cooled to room temperature, the feed is taken out, and then the feed is cut into granular feed through a crusher. Then put the feed into the injection machine and heat it to 185°C for injection. The injection pressure is 80MPa, the holding pressure is 70MPa, and the mold temperature is 80°C. Two identical hollow node hemispherical blanks are prepared. Put the two blanks into the degreasing furnace for nitric acid catalytic degreasing. The degreasing temperature is 125°C, the acid feed rate is 1.3g / min, and the degreasing time is 8h. After degreasing, the end...

Embodiment 2

[0049] The raw material is TC4 powder mixed with 30% hydrogenated dehydrogenation powder and atomized powder, the median particle size is 12.5 μm, mixed with a plastic-based binder, the binder includes 82wt.% polyoxymethylene, 6wt.% high-density polyethylene , 7wt.% polypropylene, 2wt.% microcrystalline wax and 3wt.% stearic acid. The mixing temperature is 190°C, and the time is 2 hours. After the mixing is completed and cooled to room temperature, the feed is taken out, and then the feed is cut into granular feed through a crusher. Then put the feed into the injection machine and heat it to 195°C for injection, the injection pressure is 90MPa, the holding pressure is 85MPa, the mold temperature is 110°C, and two hollow node ball blanks are prepared. Put the two blanks into the degreasing furnace for nitric acid catalytic degreasing, the degreasing temperature is 125°C, the acid feed rate is 1.5g / min, the degreasing time is 8h, and then the end surface of the degreasing hemisp...

Embodiment 3

[0052] The raw material is TC4 powder mixed with 20% hydrogenated dehydrogenation powder and atomized powder, the median particle size is 18.6 μm, mixed with a plastic-based binder, the binder includes 88wt.% polyoxymethylene, 4wt.% high-density polyethylene , 4wt.% polypropylene, 3.5wt.% microcrystalline wax and 0.5wt.% stearic acid. The mixing temperature is 140°C, and the time is 1 hour. After the mixing is completed and cooled to room temperature, the feed is taken out, and then the feed is cut into granular form by a crusher. Then put the feed material into the injection machine and heat it to 145°C for injection. The injection pressure is 50MPa, the holding pressure is 45MPa, and the mold temperature is 70°C to prepare two hollow node ball blanks. Put the two blanks into the degreasing furnace for nitric acid catalytic degreasing, the degreasing temperature is 120°C, the acid feed rate is 1.5g / min, the degreasing time is 12h, and then the end surface of the degreasing he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com