Preparation method of graphite electrode for electric-arc furnace

A graphite electrode and electric arc furnace technology, applied in the field of improved electric arc furnace graphite electrode preparation, graphite electrode preparation, can solve the problems of graphite electrode short service life, large oxidation loss, limited inhibition, etc., to reduce the occurrence of fracture accidents, Improve cohesion and anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

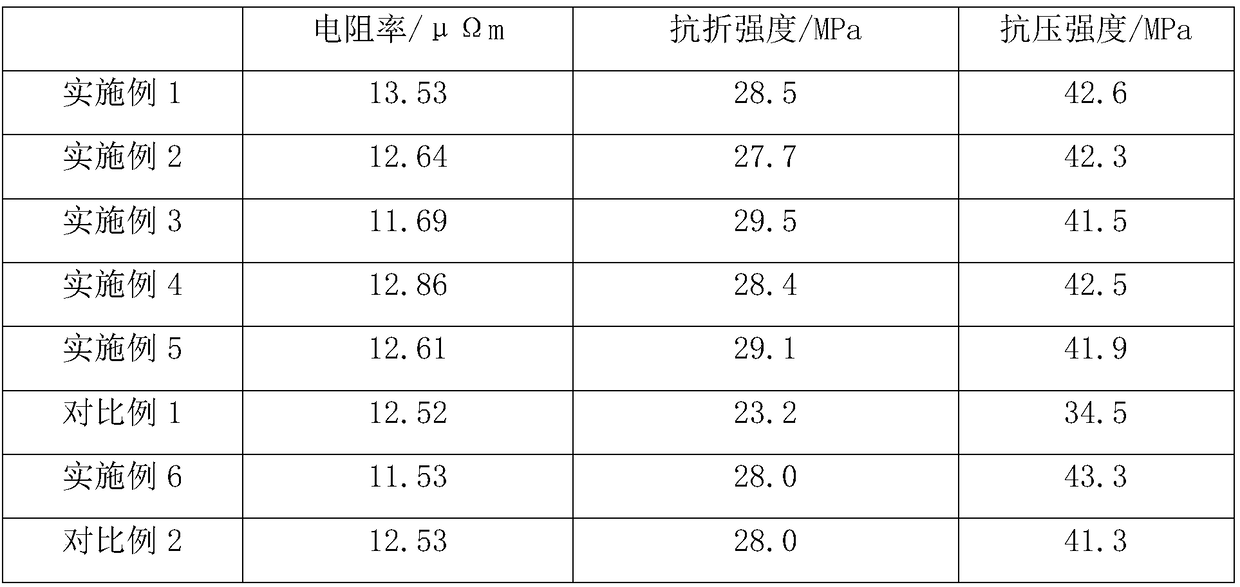

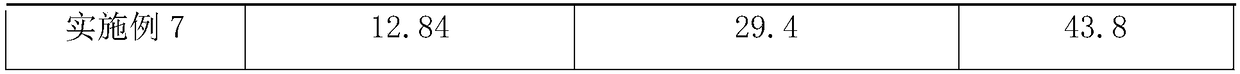

Examples

Embodiment 1

[0028] A method for preparing an electric arc furnace graphite electrode, comprising the following steps:

[0029] (1) Take 57% of petroleum coke particles, 5% of aluminum oxide powder, 3% of calcium oxide, 15% of graphite powder particles, and 20% of asphalt by weight percentage.

[0030] (2) First introduce petroleum coke particles, alumina powder, calcium oxide, and graphite powder particles into the kneading pot, and simultaneously raise the temperature to 122°C, and knead for 30 minutes;

[0031] (3) Heat the asphalt to 160°C to melt, add it to the kneading pot in step 2, control the temperature of the kneading pot to 155°C, and then keep kneading for 20 minutes.

[0032] (4) After the kneading in step 3 is completed, the material is introduced into a forming mold, pressurized to 20 MPa, and kept under pressure for 20 minutes to obtain a blank to be roasted.

[0033] (5) The blank to be roasted was heated to 500°C at a heating rate of 10°C / min under a nitrogen protective...

Embodiment 2

[0036] A method for preparing an electric arc furnace graphite electrode, comprising the following steps:

[0037] (1) Take 54% of petroleum coke particles, 4% of aluminum oxide powder, 2% of calcium oxide, 15% of graphite powder particles, and 25% of asphalt by weight percentage.

[0038] (2) First introduce petroleum coke particles and graphite powder particles into the kneading pot, add alumina powder and 1 / 3 of the total amount of calcium oxide, heat up to 122°C, knead for 5 minutes, add alumina powder, calcium oxide total 1 / 3 of the amount, knead for 5 minutes, add the remaining alumina powder and calcium oxide, and continue kneading for 20 minutes;

[0039] (3) Heat the asphalt to 160°C to melt, add it to the kneading pot in step 2, control the temperature of the kneading pot to 155°C, and then keep kneading for 20 minutes.

[0040] (4) After the kneading in step 3 is completed, the material is introduced into a forming mold, pressurized to 20 MPa, and kept under pressu...

Embodiment 3

[0044] A method for preparing an electric arc furnace graphite electrode, comprising the following steps:

[0045] (1) Take 60% of petroleum coke particles, 3% of aluminum oxide powder, 3% of calcium oxide, 10% of graphite powder particles, and 24% of asphalt by weight percentage.

[0046] (2) First introduce petroleum coke particles and graphite powder particles into the kneading pot, add alumina powder and 1 / 3 of the total amount of calcium oxide, heat up to 122°C, knead for 5 minutes, add alumina powder, calcium oxide total 1 / 3 of the amount, knead for 5 minutes, add the remaining alumina powder and calcium oxide, and continue kneading for 20 minutes;

[0047] (3) Heat the asphalt to 170°C to melt, keep it warm for 10 minutes, then add the asphalt to the kneading pot in step 2, control the temperature of the kneading pot to rise to 155°C, and then keep warm and knead for 20 minutes.

[0048] (4) After the kneading in step 3 is completed, the material is introduced into a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com