Special graphene master batch for heavy duty anticorrosion dry powder coating and preparation method

A technology of anti-corrosion dry powder and graphene, which is applied in the direction of anti-corrosion coatings, powder coatings, polyurea/polyurethane coatings, etc., can solve the problems of affecting anti-corrosion performance and irrational barrier performance of coatings, and achieve good chemical resistance and excellent anti-corrosion performance , The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

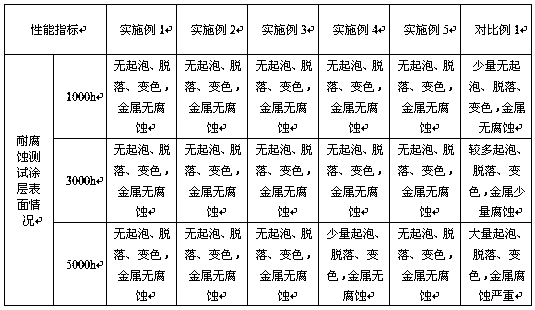

Examples

Embodiment 1

[0032] The preparation process is:

[0033] (1) Add graphene microflakes and sericite whose diameter-thickness ratio is greater than 50 into deionized water, ultrasonically disperse evenly, age for 24 hours, filter, and dry to prepare a flake inorganic carrier loaded with graphene microflakes ;

[0034] (2) Mix the flaky inorganic carrier loaded with graphene microflakes prepared in step (1) with a dispersant and a catalyst evenly, and then add it to deionized water containing an initiator and a photocurable urethane acrylate prepolymer, Ultrasonic dispersion is uniform, and a sheet-like carrier coated with photocurable polyurethane acrylate prepolymer is obtained; the dispersant is tannic acid; the catalyst is titanium tetrachloride; the initiator is TPO;

[0035] Among the raw materials, 15 parts by weight of graphene microchips, 27 parts by weight of sheet-like inorganic carrier, 1 part by weight of dispersant, 2 parts by weight of catalyst, 2 parts by weight of initiator,...

Embodiment 2

[0038] The preparation process is:

[0039] (1) Add graphene microflakes and sericite whose diameter-thickness ratio is greater than 50 into deionized water, ultrasonically disperse evenly, age for 24 hours, filter, and dry to prepare a flake inorganic carrier loaded with graphene microflakes ;

[0040] (2) Mix the flaky inorganic carrier loaded with graphene microflakes prepared in step (1) with a dispersant and a catalyst evenly, and then add it to deionized water containing an initiator and a photocurable urethane acrylate prepolymer, Ultrasonic dispersion is uniform, and a sheet-like carrier coated with photocurable polyurethane acrylate prepolymer is obtained; the dispersant is sodium linoleate; the catalyst is titanium trichloride; the initiator is 1173;

[0041] Among the raw materials, 14 parts by weight of graphene microchips, 26 parts by weight of sheet-like inorganic carrier, 1 part by weight of dispersant, 1 part by weight of catalyst, 2 parts by weight of initiat...

Embodiment 3

[0044] The preparation process is:

[0045] (1) Add graphene microflakes and sericite whose diameter-thickness ratio is greater than 50 into deionized water, ultrasonically disperse evenly, age for 24 hours, filter, and dry to prepare a flake inorganic carrier loaded with graphene microflakes ;

[0046] (2) Mix the flaky inorganic carrier loaded with graphene microflakes prepared in step (1) with a dispersant and a catalyst evenly, and then add it to deionized water containing an initiator and a photocurable urethane acrylate prepolymer, Ultrasonic dispersion is uniform, and a sheet-like carrier coated with photocurable polyurethane acrylate prepolymer is obtained; the dispersant is sodium linoleate; the catalyst is vanadyl triiodide; the initiator is 819;

[0047] Among the raw materials, 15 parts by weight of graphene microchips, 29 parts by weight of sheet-like inorganic carrier, 2 parts by weight of dispersant, 2 parts by weight of catalyst, 2 parts by weight of initiator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com