A method for producing high-purity crystalline maltose

A technology of maltose and maltose amylase, which is applied in the field of food and pharmaceutical starch sugar production, can solve the problems of high-purity crystalline maltose production starting late and high price, and achieve stable product quality, improve crystallization purity, and realize the effect of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

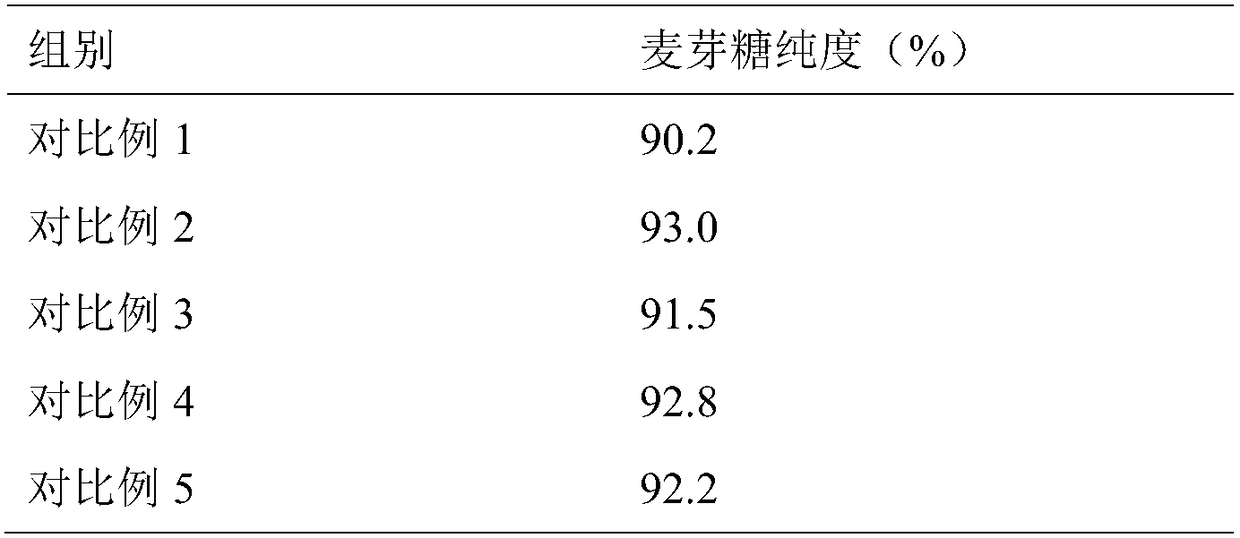

Examples

Embodiment 1

[0026] Synthesize the gene sequence encoding the maltogenic amylase shown in SEQ ID NO.1, connect it to pET24a, transform the ligated product into Escherichia coli JM109 competent cells, extract the plasmid for verification, the result is correct, and transform the plasmid into Escherichia coli BL21 (DE3) competent cells For the cells, the transformants were picked and cultured overnight at 37° C. in LB liquid medium (containing 100 mg / L kanamycin). Pick positive clones, cultivate seed liquid, and transfer to TB liquid fermentation medium. After culturing at 37°C for 2 hours, add 0.01mM IPTG at a final concentration for induction, and continue to culture and ferment on a shaker at 25°C for 48 hours, then centrifuge the fermentation broth at 4°C and 8000rpm for 10 minutes to remove bacteria, and collect the fermentation supernatant.

[0027] Slowly add 50% (NH 4 ) 2 SO 4 , placed overnight at 4°C, centrifuged at 8000rpm for 20min at 4°C, and collected the precipitate. After...

Embodiment 2

[0029] (1) Prepare 20% (w / v) potato starch solution, adjust pH to 5.5, add 30U / g dry starch α-amylase, add 24U / g dry starch pullulanase and 10U after spray liquefaction treatment β-amylase / g dry starch, stirred at 60°C for 24 hours, and carried out a saccharification. Then add 20U / g maltose amylase of dry starch, stir at 60°C for 8 hours, and carry out secondary saccharification. When the saccharification is finished, the measured maltose content is 96.4%.

[0030] (2) Decolorization and filtration: heat up to kill enzymes, add activated carbon to the saccharification solution for decolorization, and filter through filter paper to make the sugar solution clear and transparent, free of foreign matter and impurities visible to the naked eye.

[0031] (3) Purification and concentration: the mass concentration of the sugar solution is concentrated to 70% by anion-cation exchange resin treatment to a conductivity of 30 μs / cm.

[0032] (4) Stirring crystallization: 1.5% by mass of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com