Treatment method of laterite nickel ore

A technology of lateritic nickel ore and treatment method, applied in nickel sulfate, process efficiency improvement, cobalt sulfate, etc., can solve problems such as high concentration of sodium ions, lower production efficiency, increase production cost, etc., to reduce salt concentration, The effect of improving production efficiency and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Mix the slurry of lateritic nickel ore 1 (see Table 1 for the composition) with sulfuric acid of 98% concentration for pressure leaching treatment to obtain a leachate; wherein, the feed concentration of the pressure leaching slurry is 40%, and the temperature of the pressure leaching treatment is 255 degrees Celsius , the pressure is 48bar, the leaching time is 1h, and the terminal acidity is 40g / L;

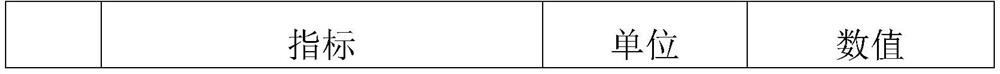

[0065] Table 1

[0066]

[0067] Add iron and aluminum in the limestone slurry precipitation solution to the obtained leaching solution; one of the first stage of neutralization and precipitation of iron and aluminum is precipitation at a temperature of 75°C for 5 hours, and the pH value of the end point is 3.8; the second stage of neutralization of precipitation of iron and aluminum is at 65°C Precipitate at a certain temperature for 4 hours, and the final pH value is 4.8.

[0068] After removing iron and aluminum, the nickel-cobalt-containing solution is added to th...

Embodiment 2

[0073] Mix the pulp of laterite nickel ore 2 (see Table 3 for the composition) with concentrated sulfuric acid of 98% concentration and carry out pressure leaching treatment to obtain a leachate; wherein, the feed concentration of the pressure leaching pulp is 45%, and the temperature of the pressure leaching treatment is 250 Celsius, the pressure is 46bar, the leaching time is 1h, and the terminal acidity is 32g / L;

[0074] table 3

[0075]

[0076] Add iron and aluminum in the limestone slurry precipitation solution to the obtained leaching solution; one of the first stage of neutralization and precipitation of iron and aluminum is precipitation at a temperature of 70°C for 4 hours, and the pH value of the end point is 3.5; the second stage of neutralization of precipitation of iron and aluminum is at 60°C Precipitate at a certain temperature for 3.5 hours, and the final pH value is 4.6.

[0077] After removing iron and aluminum, the nickel-cobalt-containing solution is ...

Embodiment 3

[0082] Mix the slurry of lateritic nickel ore 3 (see Table 5 for the composition) with concentrated sulfuric acid of 98% concentration and carry out pressure leaching treatment to obtain a leachate; wherein, the feeding concentration of the pressure leaching slurry is 43%, and the temperature of the pressure leaching treatment is 252 Celsius, the pressure is 46.1bar, the leaching time is 1h, and the terminal acidity is 45g / L;

[0083] table 5

[0084]

[0085] Add iron and aluminum in the limestone slurry precipitation solution to the obtained leaching solution; one of the first stage of neutralization and precipitation of iron and aluminum is precipitation at a temperature of 72 ° C for 4.5 hours, and the pH value of the end point is 3.7; the second stage of neutralization and precipitation of iron and aluminum is at 60 Precipitate at a temperature of ℃ for 4 hours, and the final pH value is 4.5.

[0086] The nickel-cobalt-containing solution after removing iron and alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com