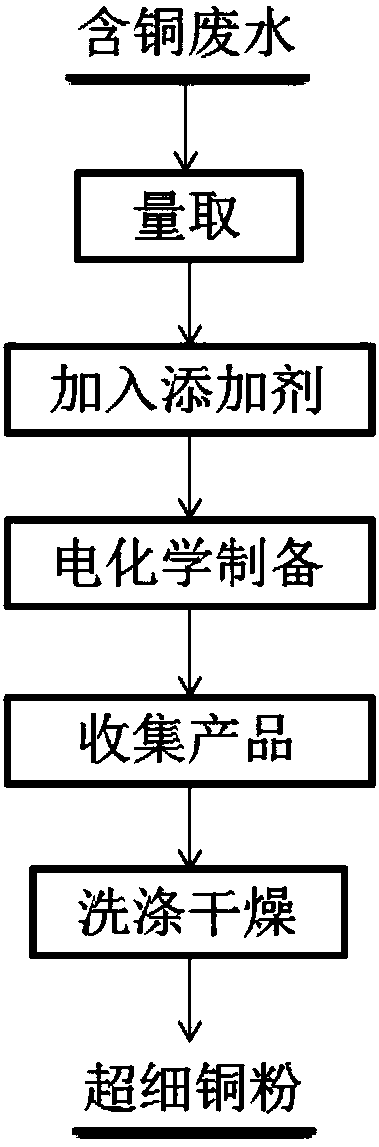

Preparation method of ultrafine spherical copper powder

A technology of ultra-fine spherical copper powder and copper powder, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of large amount of additives, poor dispersion, and unsuitability for large-scale industrial production, and achieve reduced size, uniform shape and quality , Conducive to the effect of ecological environment protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

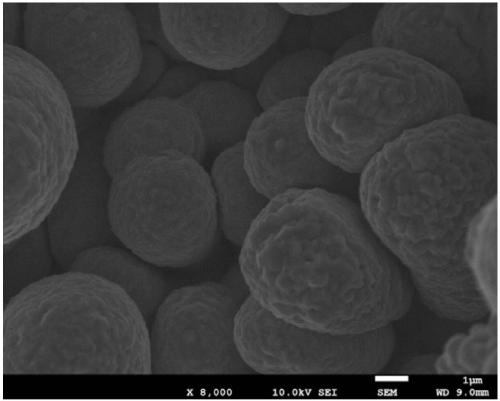

Embodiment 1

[0051] (1) Use the electroplating factory plating piece washing wastewater as the copper-containing solution, feed nitrogen into the copper-containing solution for 30 minutes, adjust the pH of the copper-containing solution to 1 after the ventilation is completed, and then add potassium ferrocyanide as the electrolyte, The concentration of potassium ferrocyanide in the electrolyte is 0.5g / L;

[0052] (2) The electrolytic solution obtained in step (1) is passed into the swirl electrolyzer, and 316 stainless steel is used as the working electrode, and the working electrode area is 200cm 2 , the coated titanium is the counter electrode, the shapes of the working electrode and the counter electrode are rectangular plate and column respectively, the stirring rate is controlled to 100r / min, and the current density is 100A / m 2 , the electrolysis temperature is 35°C, and the electrolysis is carried out for 2 hours. After the electrolysis is completed, copper powder is obtained on the ...

Embodiment 2

[0056] (1) Use the pickling water from the iron and steel plant as the copper-containing solution, feed nitrogen into the copper-containing solution for 15 minutes, adjust the pH of the copper-containing solution to 1 after the aeration, and then add potassium ferrocyanide as the electrolyte, electrolyze The concentration of potassium ferrocyanide in the liquid is 0.8g / L;

[0057] (2) The electrolyte obtained in step (1) is passed into the swirl electrolyzer, and 316 stainless steel is used as the working electrode, and the working electrode area is 300cm 2 , the coated titanium is the counter electrode, the shapes of the working electrode and the counter electrode are rectangular plate and column respectively, the stirring rate is controlled to 150r / min, and the current density is 150A / m 2 , the electrolysis temperature is 35°C, and the electrolysis is carried out for 2 hours. After the electrolysis is completed, copper powder is obtained on the working electrode;

[0058] (...

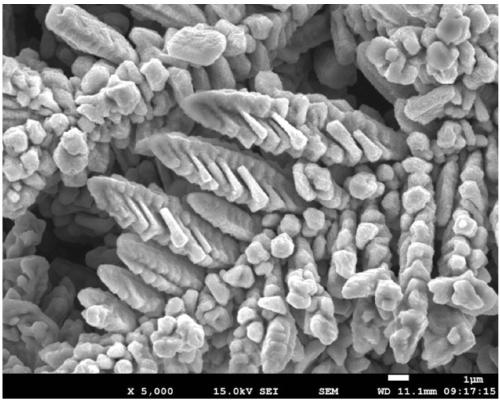

Embodiment 3

[0061] (1) Use the tailings drainage of the concentrator as the copper-containing solution, feed argon into the copper-containing solution for 60 minutes, adjust the pH of the copper-containing solution to 2 after the aeration, and then add potassium ferrocyanide as the electrolyte, The concentration of potassium ferrocyanide in the electrolyte is 1.1g / L;

[0062] (2) The electrolyte that step (1) obtains is passed into the cyclone electrolyzer, uses 316 stainless steel as working electrode, and working electrode area is 350cm 2 , the coated titanium is the counter electrode, the shapes of the working electrode and the counter electrode are rectangular plate and column respectively, the stirring rate is controlled to 200r / min, and the current density is 200A / m 2 , the electrolysis temperature is 20°C, and the electrolysis is carried out for 2.5 hours. After the electrolysis is completed, copper powder is obtained on the working electrode;

[0063] (3) The working electrode is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com