Method for preparing three-dimensional graphene/high molecular polymer composite material by reinforcing three-dimensional graphene skeleton structure

A high-molecular polymer and graphene skeleton technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, electrical components, etc., can solve high sealing requirements, time-consuming and energy-consuming, and low efficiency and other problems, to achieve the effect of strengthening strength, making up for fragility, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

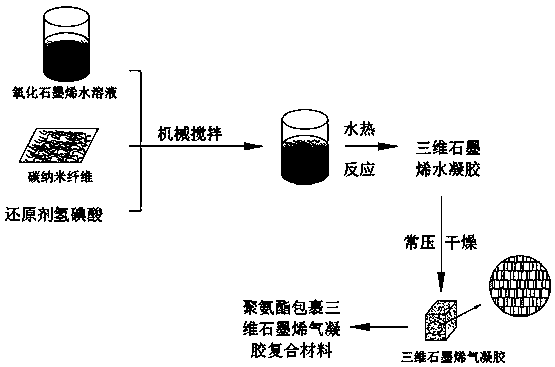

[0029] A kind of method that strengthens three-dimensional graphene framework structure to prepare three-dimensional graphene / macromolecular polymer composite material, such as figure 1 As shown, the specific steps are as follows:

[0030] (1) According to the document "Correction to Improved Synthesis of Graphene Oxide", graphene oxide was prepared by improving the hummers method; according to the document "Chemical Vapor Deposition on Activated Carbon to Grow Carbon Nanofibers", carbon nanofibers were prepared; graphene oxide was prepared according to the mass volume The ratio (mg:mL) is 5:1, mechanical stirring is dissolved in water, the mechanical stirring speed is 600r / min, and the graphene oxide aqueous solution is obtained by mixing; according to the mass ratio of carbon nanofibers and graphene oxide is 4:25 Ratio, adding carbon nanofibers to the graphene oxide aqueous solution to obtain the graphene oxide aqueous solution containing carbon nanofibers, then adding the r...

Embodiment 2

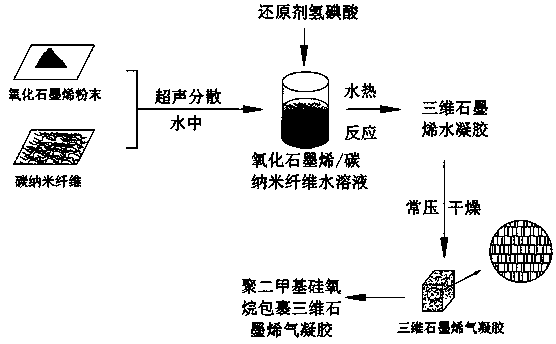

[0038] A method for preparing a three-dimensional graphene / polymer composite material by enhancing a three-dimensional graphene skeleton structure, the specific steps are as follows:

[0039] (1) Ultrasonic dispersion and dissolution of graphene oxide in water according to the ratio of mass volume ratio (mg:mL) of 5:1, the ultrasonic power is 150W, the frequency is 20KHz, and the graphene oxide aqueous solution is obtained by mixing; according to the carbon nanofiber and Graphene oxide mass ratio is the ratio of 14:25, and carbon nanofiber is added in graphene oxide aqueous solution, obtains the graphene oxide aqueous solution containing carbon nanofiber, then according to graphene oxide and reducing agent mass ratio is 1:5 The reducing agent hydrazine hydrate was added in proportion, and mixed to obtain a mixed solution; the mixing method was ultrasonic dispersion, the ultrasonic power was 150W, and the frequency was 20KHz; both graphene oxide and carbon nanofibers were commer...

Embodiment 3

[0046] A method for preparing a three-dimensional graphene / polymer composite material by enhancing a three-dimensional graphene skeleton structure, the specific steps are as follows:

[0047] (1) Ultrasonic dispersion and dissolution of graphene oxide in water according to the ratio of mass volume ratio (mg:mL) of 5:1, the ultrasonic power is 150W, the frequency is 20KHz, and the graphene oxide aqueous solution is obtained by mixing; according to the carbon nanofiber and Graphene oxide mass ratio is the ratio of 9:25, carbon nanofiber is added in graphene oxide aqueous solution, obtains the graphene oxide aqueous solution containing carbon nanofiber, then according to graphene oxide and reducing agent mass ratio is 1:5 Proportional addition of reducing agent is hydrazine hydrate, and mixing to obtain a mixed solution; the mixing method is ultrasonic dispersion, the ultrasonic power is 150W, and the frequency is 20KHz; both graphene oxide and carbon nanofibers are commercially a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com