A porous nano silicon-carbon composite material prepared by a magnesium thermal reduction method and a preparation method thereof

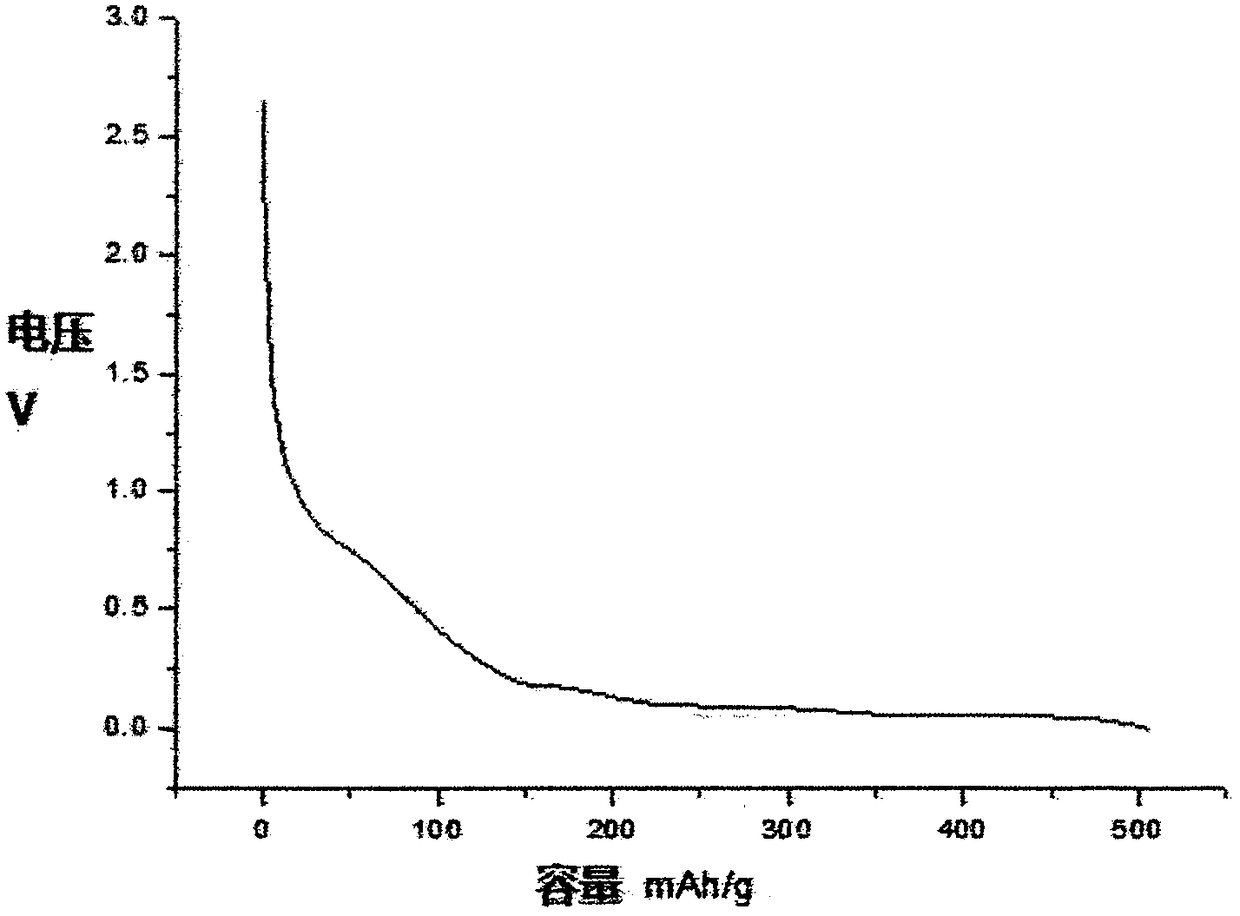

A technology of carbon composite materials and nanocomposites, applied in the direction of nanocarbon, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of reducing cycle life, shedding of negative active materials, and reducing the reversible capacity of silicon-carbon composite materials and other problems, to achieve the effect of easy removal, less residue, and improved reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of polystyrene (PS) microsphere emulsion:

[0034] Dissolve 3g of polyvinylpyrrolidone in 180g of water, add 8.5g of styrene, stir and heat to 70°C, then dissolve 0.18g of initiator azobisisobutylamidine hydrochloride in 30g of water, and add it to the glass reactor for reaction In 24 hours, polystyrene (PS) microsphere emulsion was obtained, and the particle size range of the microsphere was 200nm;

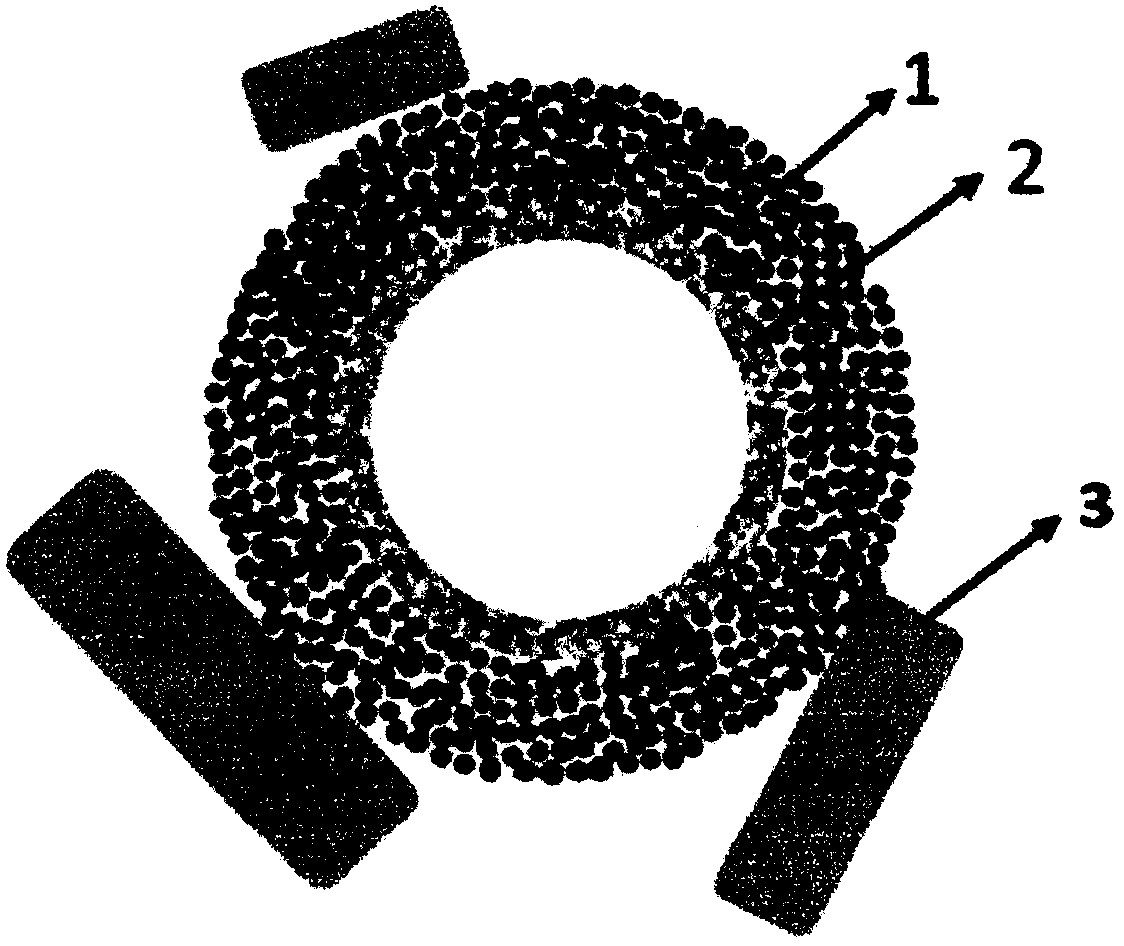

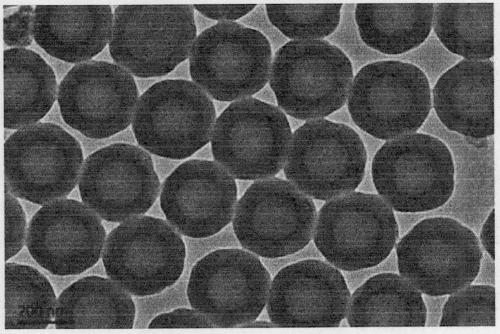

[0035] (2) Polystyrene / silica core-shell structure composite (PS / SiO 2 ) preparation:

[0036] Get 6g polystyrene microsphere emulsion and disperse in 100g water, stir 10 minutes, continue to add and contain 0.6g templating agent cetyltrimethylammonium bromide (CTAB), the mixed solution of 39.5g ethanol, 1g ammoniacal liquor, stir 30 Minutes, slowly drop 1.4g tetraethyl tetrasilicate (TEOS) into the above mixed solution, keep stirring at 30°C for 6 hours, centrifuge, and dry in a vacuum oven at 110°C for 5 hours to obtain polystyrene / dioxide Silicon core...

Embodiment 2

[0052] (1) Preparation of polystyrene (PS) microsphere emulsion:

[0053] Dissolve 6g of polyvinylpyrrolidone in 180g of water, add 12g of styrene, stir and heat to 70°C, then dissolve 0.7g of initiator azobisisobutylamidine hydrochloride in 30g of water, add it to the reaction system and react for 18 hours , to obtain polystyrene (PS) microsphere emulsion, the microsphere particle size range is 100nm;

[0054] (2) Polystyrene / silica core-shell structure composite (PS / SiO 2 ) preparation:

[0055] Get 8.0g polystyrene microsphere emulsion and disperse in 100g water, stir for 15 minutes, continue to add the mixed solution that contains 3g templating agent cetyltrimethylammonium bromide (CTAB), 50g ethanol, 1g ammonia water, stir for 30 minutes , 7.0g tetraethyl orthosilicate (TEOS) was slowly added dropwise to the above mixed solution, stirred continuously at 35°C for 4 hours, centrifuged and dried to obtain polystyrene / silica core-shell structure composite (PS / SiO 2 ) produ...

Embodiment 3

[0064] (1) Preparation of polystyrene (PS) microsphere emulsion:

[0065] Dissolve 1g of polyvinylpyrrolidone in 180g of water, add 5g of styrene, stir and heat to 70°C, then dissolve 0.1g of initiator azobisisobutylamidine hydrochloride in 30g of water, and add it to the glass reactor for reaction 12 Hour, obtain polystyrene (PS) microsphere emulsion, the microsphere particle size scope is 50nm;

[0066] (2) Polystyrene / silica core-shell structure composite (PS / SiO 2 ) preparation:

[0067]Get 3.0g polystyrene microsphere emulsion and disperse in 100g water, stir for 12 minutes, continue to add the mixed solution containing 1g templating agent cetyltrimethylammonium bromide (CTAB), 30g ethanol, 1g ammonia water, stir for 30 minutes , slowly drop 1g tetraethyl orthosilicate (TEOS) into the above mixed solution, continue to stir at 25°C for 9 hours, centrifuge, and dry in a vacuum oven at 110°C for 5h to obtain polystyrene / silica core-shell Structural composite (PS / SiO 2 ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com