A kind of ammonium polyphosphate resistant to migration and precipitation resistance under high temperature and high humidity conditions in acrylic emulsion textile coating and preparation method thereof

A technology of acrylic emulsion and ammonium polyphosphate, which is applied in textiles and papermaking, dyed organic silicon compound treatment, fibrous fillers, etc., can solve the problems of long reaction time, large coating amount, and reduced solubility, and achieves a simple preparation method, Enhanced curing form, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

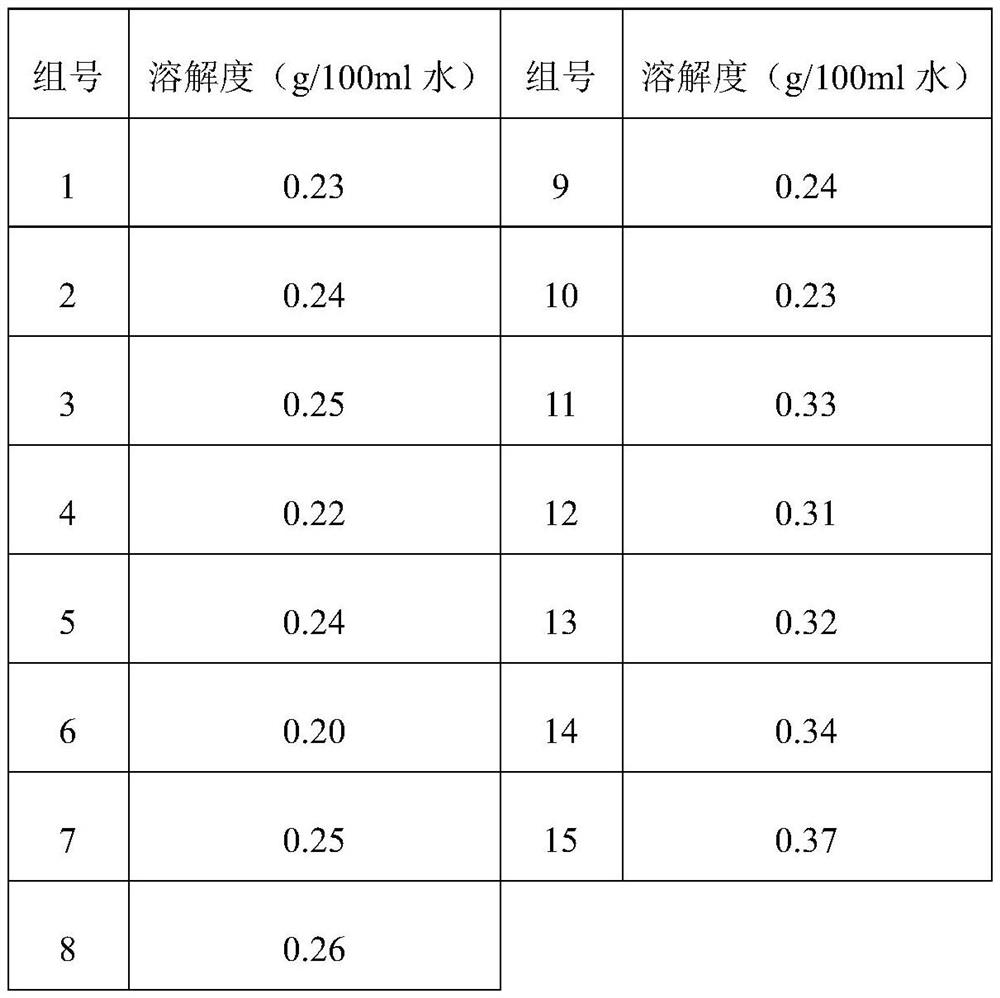

[0018] A preparation method of APP resistant to migration and precipitation resistance under high temperature and high humidity conditions in an acrylic emulsion textile coating, comprising the following steps:

[0019] Add APP powder into the water under stirring; it should be noted that, in this embodiment, the mass ratio of water to APP powder is further 1-3:1. To ensure that the APP powder can be fully dissolved in water.

[0020] Then, a coupling agent is added dropwise in an amount of 2-10% by weight of the APP powder; it should be noted that, in this embodiment, the coupling agent contains active groups that can react with unsaturated bonds in the acrylic emulsion. The reactivity of these reactive groups is capable of reacting with the functional groups on the acrylate, thereby bonding the silicone component to the acrylic resin molecule.

[0021] In this embodiment, the inventors creatively found that when the coupling agent includes epoxy silane coupling agent, vinyl...

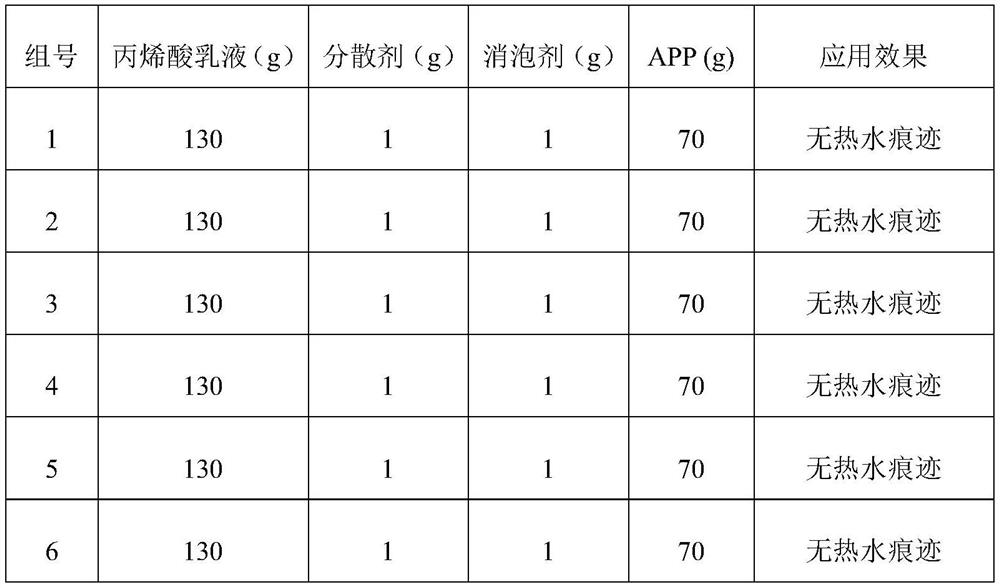

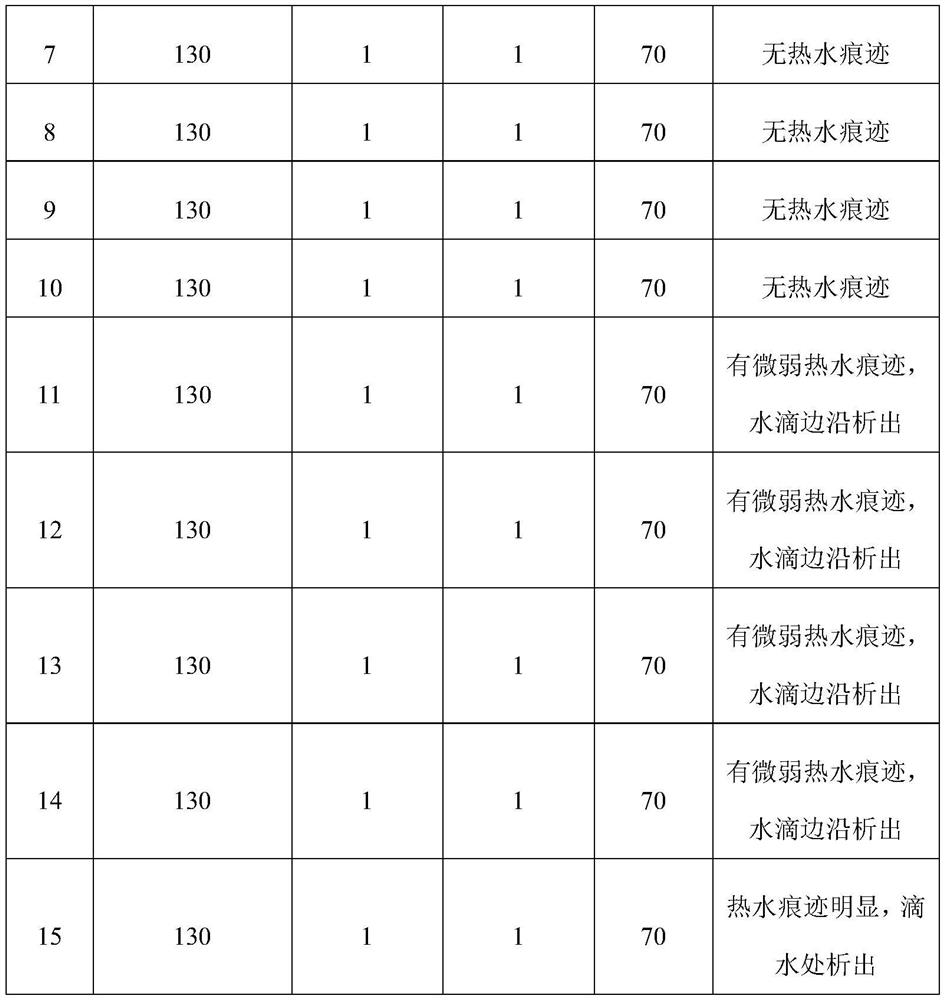

Embodiment 1

[0026] This example provides a method for preparing APP that is resistant to migration and precipitation under high temperature and high humidity conditions in an acrylic emulsion textile coating, including the following steps:

[0027] Take a certain amount of 500g pure water, add 500g APP under stirring state, then add 2g epoxy silane coupling agent KH560, 3g vinyl silane coupling agent KH171 and 5g methacryloxy coupling agent dropwise under stirring state KH570, after the dropwise addition, stir for 0.5h to obtain the mixture, then filter the mixture until no obvious water droplets exist, and dry the filtered powder in an oven at 120°C for 2h to obtain modified APP.

Embodiment 2

[0029] This example provides a method for preparing APP that is resistant to migration and precipitation under high temperature and high humidity conditions in an acrylic emulsion textile coating, including the following steps:

[0030] Take a certain amount of 500g pure water, add 500g APP under stirring state, then add 2g epoxy silane coupling agent KH560, 3g vinyl silane coupling agent KH171 and 5g methacryloxy coupling agent dropwise under stirring state KH570, after the dropwise addition, stir for 2 hours to obtain a mixture, then filter the mixture until no obvious water droplets exist, and dry the filtered powder in an oven at 120°C for 2 hours to obtain modified APP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com