Kraft board paper and manufacturing method thereof

A technology for kraft boxes and cardboard, applied in the field of papermaking, can solve the problems of high manufacturing cost, low gloss of paper, low retention rate of inorganic fillers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In the preparation of liquefied GCC slurry, the powder GCC with a size of 60 grades is selected, the dispersant is triethylhexyl phosphoric acid, and the polyacrylamide derivatives with benzene ring branches in a three-dimensional network structure are polyacrylamide and The reaction product of phenolic resin has a number-average relative molecular weight of 2.5 million, and an anionic polyacrylamide has a number-average relative molecular weight of 9 million.

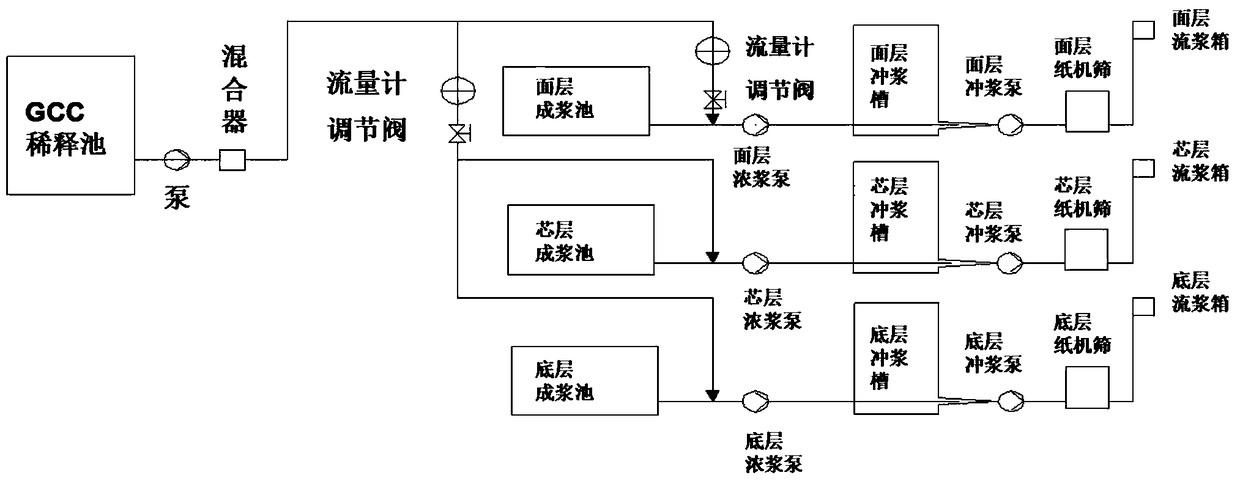

[0036] The paper machine used to manufacture kraft linerboard is equipped with headbox, wire section, press section, pre-drying section, sizing press section, post-drying section, hard calender, and winder in sequence along the horizontal direction; The wire section is designed as a triple-fold wire; the headbox is a full-flow headbox, and the press section is designed as two shoe presses, or one large roll diameter and one shoe press; the front The drying section adopts a single hanging net arrangement drying c...

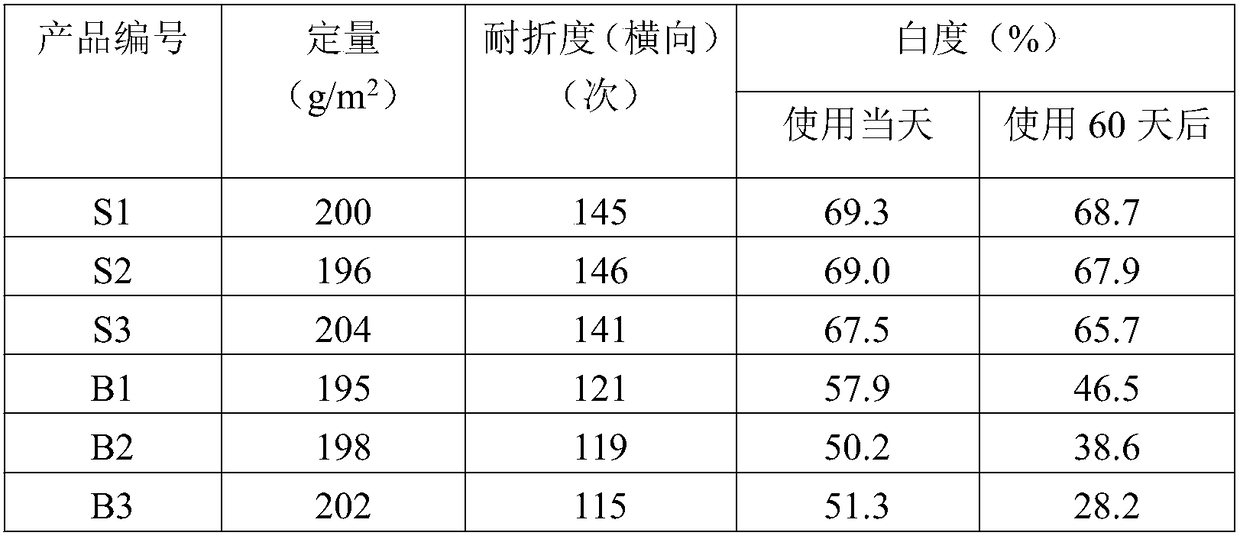

Embodiment 2

[0044] The paper machine selected in this embodiment and the preparation method of kraft liner paper are the same as in Example 1, the only difference is that in the preparation of GCC slurry, the GCC mass fraction of 90% GCC water with a size specification of 60 grades is selected. Dispersions. The final product is denoted as S2. GCC aqueous dispersion is used to prepare liquefied GCC slurry, and the amount of each raw material should be calculated according to the actual mass of GCC.

Embodiment 3

[0046] The paper machine and the preparation method of the kraft liner selected in this example are the same as those in Example 1, the only difference is that in the preparation of the GCC slurry, the powder GCC with a size specification of 40 grades is selected. The final product is denoted as S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com