V/Zr-MOF catalyst for preparing phenol from benzene through direct hydroxylation and preparation method of V/Zr-MOF catalyst

A catalyst and hydroxylation technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. The problem of low atom utilization, etc., to achieve the effects of easy separation, good catalytic activity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

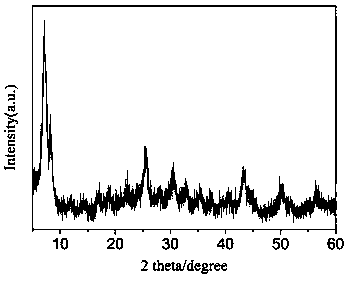

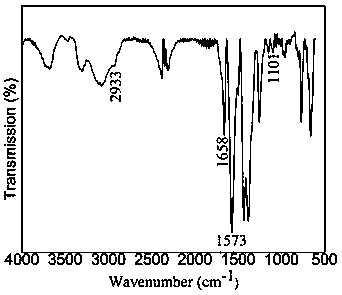

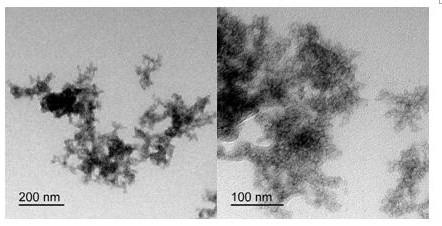

[0022] Take 0.8478 g of ZrCl 4 Dissolve in 150 mL of DMF until clear to obtain A; add 5.7 mL of glacial acetic acid dropwise to the clear solution A, stir at 55°C for 20 min to obtain B; then take 0.622 g of 2-amino p- Dissolve phthalic acid in a certain amount of DMF until it becomes clear, then add 0.25 mL of distilled water, and add the mixed solution dropwise to the above mixed solution B to obtain C; finally, take 0.3 g of vanadyl acetylacetonate and dissolve it in a certain Measure the DMF solution until it is clear, and add it dropwise to the mixed solution C to obtain D; after the mixed solution D is continuously stirred at 120°C for 24 h, it is washed with DMF and ethanol and dried respectively to obtain the vanadium-zirconium catalyst.

[0023] The prepared catalyst was used in the hydroxylation reaction of benzene. 50 mg of catalyst, 1 mL of benzene (0.84 g), 3 mL of 70 vol.% acetic acid solution, and 0.7 g of ascorbic acid were added to a 10 mL autoclave, and a 3 M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com