High-oxidation-resistance and high-binding-force silver-coated copper powder to which tin interlayer is added and preparation method thereof

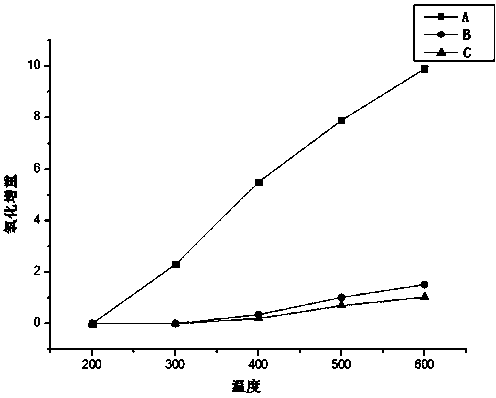

A technology of silver-coated copper powder and intermediate layer, which is used in metal processing equipment, coating, transportation and packaging, etc., can solve the problems of low oxidation resistance, insufficient bonding force, increase cost, etc., and achieve reduced porosity and denser The effect of enhancing sexuality and enhancing bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

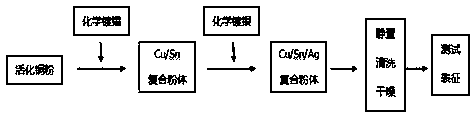

[0030] Such as figure 1 As shown, the preparation method of the silver-coated copper powder with high oxidation resistance and high binding force with the addition of tin intermediate layer of this embodiment includes the following steps:

[0031] Step (1), preparation of copper powder suspension

[0032] Dissolve 12g of copper powder in 500ml of deionized water, ultrasonically wash with 2g / L sodium hydroxide solution for 5 minutes, filter and wash to obtain a copper powder suspension.

[0033] Step (2), prepare tin plating solution:

[0034] Dissolve 11.4g of stannous chloride with 20ml of hydrochloric acid, pour 61g / L of thiourea, 50g / L of sodium hypophosphite, and 14g / L of sodium citrate solution into it in sequence to obtain a tin plating solution.

[0035] Step (3), preparation of tinned copper powder

[0036] The tin plating solution of step (2) was dropped into the copper powder suspension of step (1) at a speed of 25ml / min under ultrasonic stirring, and reacted at room temperatur...

Embodiment 2

[0045] The preparation method of the silver-coated copper powder with high oxidation resistance and high binding force with the addition of tin intermediate layer of this embodiment includes the following steps:

[0046] Step (1), preparation of copper powder suspension

[0047] Dissolve 12g of copper powder in 500ml of deionized water, ultrasonically wash with 2g / L sodium hydroxide solution for 5 minutes, filter and wash to obtain a copper powder suspension.

[0048] Step (2), prepare tin plating solution:

[0049] Dissolve 5.04 g of stannous chloride with 10 ml of hydrochloric acid, and pour 28 g / L of thiourea, 22 g / L of sodium hypophosphite and 6 g / L of sodium citrate solution into it in sequence to obtain a tin plating solution.

[0050] Step (3), preparation of tinned copper powder

[0051] The tin plating solution of step (2) was dropped into the copper powder suspension of step (1) at a speed of 30 ml / min under ultrasonic stirring, and reacted at room temperature for 30 minutes. A...

Embodiment 3

[0058] The preparation method of the silver-coated copper powder with high oxidation resistance and high binding force with the addition of tin intermediate layer of this embodiment includes the following steps:

[0059] Step (1), preparation of copper powder suspension

[0060] Dissolve 12g of copper powder in 500ml of deionized water, ultrasonically wash with 2g / L sodium hydroxide solution for 5 minutes, filter and wash to obtain a copper powder suspension.

[0061] Step (2), prepare tin plating solution:

[0062] Dissolve 11.4g of stannous chloride with 20ml of hydrochloric acid, and pour 50g / L of thiourea, 30 / L of sodium hypophosphite and 8g / L of sodium citrate solution into it in sequence to obtain a tin plating solution.

[0063] Step (3), preparation of tinned copper powder

[0064] The tin plating solution of step (2) was dropped into the copper powder suspension of step (1) at a speed of 25ml / min under ultrasonic stirring, and reacted at room temperature for 30 minutes. After st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com