Water-based pigment self-dispersing system and preparation method thereof

A water-based pigment, self-dispersing technology, applied in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc., can solve the problems of poor stability, unstable particle size, large viscosity change, etc. Uniform, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the water-based pigment self-dispersing system of the embodiment of the present invention, it comprises the following steps:

[0026] Step A: reacting aromatic amine and cyanuric chloride to prepare a condensation product of aromatic amine and cyanuric chloride, which is a surface modifier. Wherein, the aromatic amine is one or more of p-aminobenzenesulfonic acid, p-aminobenzoic acid, anthranilic acid or anthranilic acid. The molar ratio of the condensation reaction between aromatic amine and cyanuric chloride is 1.05:2~1.05:1. Preferably, the optimal molar ratio of the condensation reaction between aromatic amine and cyanuric chloride is 1.05:1.2.

[0027] Step B: Mix the surface modifier and the pigment evenly. The pigment can be black pigment, red pigment, blue pigment or yellow pigment, and add an oxidizing agent. The oxidizing agent can be potassium permanganate, potassium chlorate or potassium perchlorate. Perform surface modification. ...

Embodiment 1

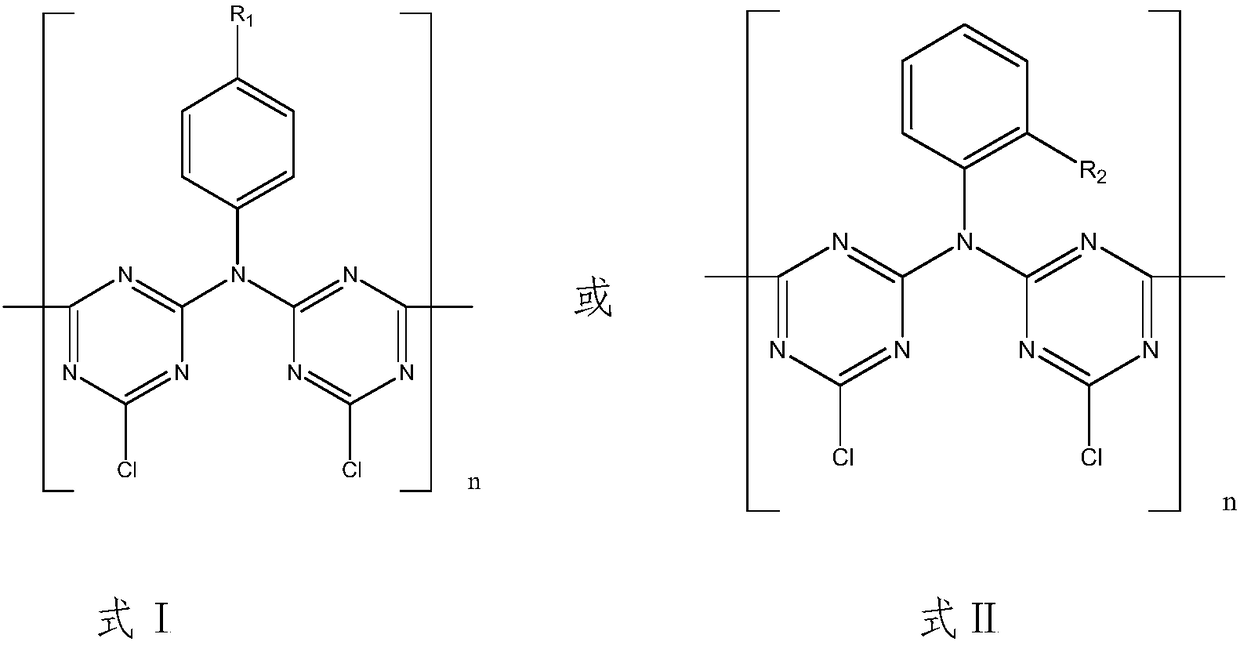

[0039] Add 65g of p-aminobenzoic acid into ultrapure water, adjust to dissolve completely with sodium hydroxide. Add 83g of cyanuric chloride to 500g of ice-water mixture and stir evenly. Slowly add the p-aminobenzoic acid solution into the cyanuric chloride ice-water mixture, stir while adding, control the temperature not to exceed 10°C, and control the pH of the reaction with a buffer solution of sodium hydroxide and sodium bicarbonate to 5-6 until When the pH does not change any more, the solution is filtered to obtain a filtrate, and a solution containing surface modifier A is obtained. Wherein, the chemical structural formula of surface modifier A is as follows:

[0040]

[0041] where n=2-6.

[0042] Beat 150g of carbon black HIBlack 900L, surface modifier A solution, and 1.5L of ultrapure water with a high-speed disperser, then add 67g of potassium permanganate, slowly raise the temperature to 60°C, and use sodium hydroxide to control the pH of the reaction solutio...

Embodiment 2

[0045]Add 80g of p-aminobenzenesulfonic acid into ultrapure water, adjust to dissolve completely with sodium hydroxide, add 103g of cyanuric chloride into 600g of ice-water mixture and stir evenly, slowly add p-aminobenzenesulfonic acid solution into trimeric chloride In the cyanide-ice water mixture, stir while adding, control the reaction temperature not to exceed 10°C, control the pH of the reaction with a buffer solution of sodium hydroxide and sodium bicarbonate to 3.5-4.5 until the pH does not change any more, filter to obtain the filtrate, and obtain the Solution of Surface Modifier B. Wherein, the chemical structural formula of surface modifier B is as follows:

[0046]

[0047] where n=3-8.

[0048] Beat 150g of carbon black Monarch 700, surface modifier B solution, and 1.5L of ultrapure water with a high-speed disperser, then add 44.5g of potassium chlorate, slowly raise the temperature to 65°C, and use sodium hydroxide to control the pH=9.0. React at ~70°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com