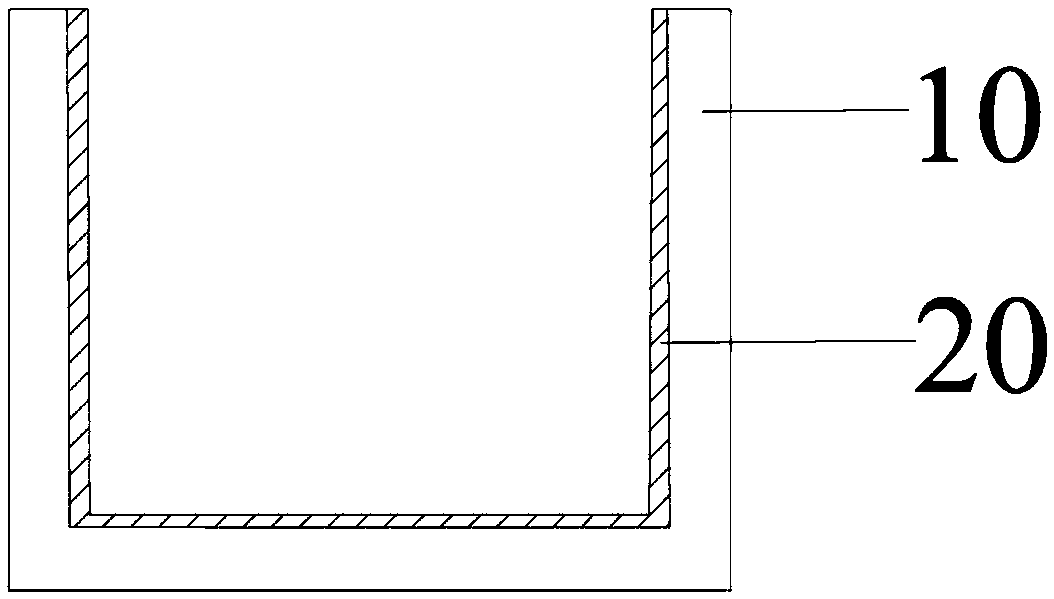

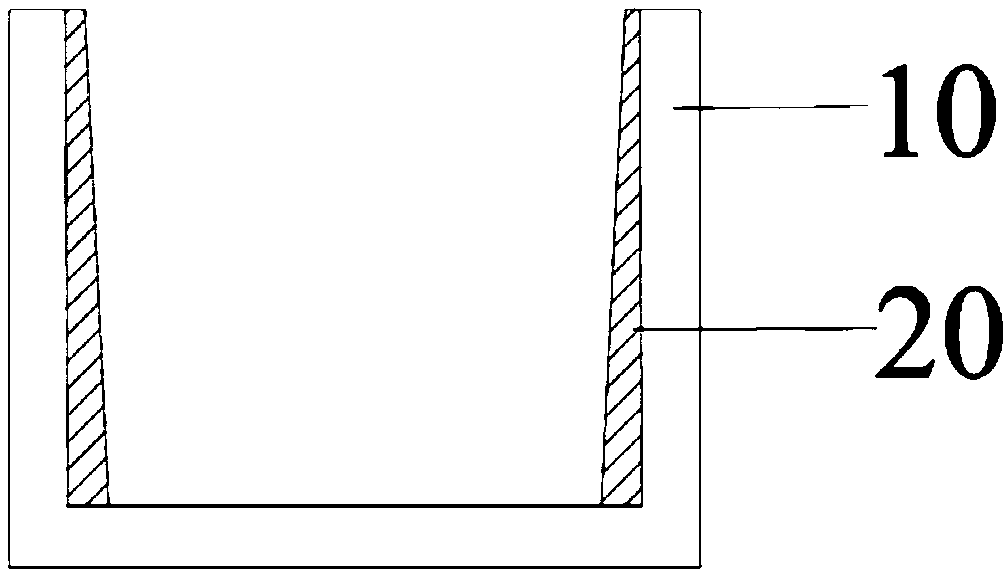

Quartz-ceramic crucible with combined structure and preparation method thereof

A technology of quartz ceramics and composite structures, applied in the field of quartz ceramic crucibles, can solve problems such as increased hard points, high reactivity, and reduced yield of silicon ingots, so as to reduce impurity content and oxygen content, reduce production costs, and reduce The effect of red fringing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] A method for preparing a composite structure quartz ceramic crucible, comprising:

[0095] Take high-purity quartz sand with a purity of 99.99% and a particle size of less than 5 mm, dissolve it in water and add zirconia balls as grinding media to obtain a quartz slurry with a solid content of 91%. Add acrylamide, N,N-methylenebisacrylamide and ammonium persulfate into the above-mentioned quartz slurry, and mix evenly to obtain a mixed slurry.

[0096] Take the crucible body, place the tempered glass inner mold in the inner cavity of the crucible body, and form a mold cavity between the inner mold and the crucible body. The above-mentioned mixed slurry is injected into the mold cavity by the pouring process, and the inner mold is removed after solidifying in a water bath at 60°C for 45 minutes, so that a layer of high-purity quartz layer is attached to the inner surface of the crucible body, and the compound is obtained after rough sandblasting. Structural quartz ceram...

Embodiment 2

[0098] A method for preparing a composite structure quartz ceramic crucible, comprising:

[0099] Take high-purity quartz sand with a purity of 99.995%, which contains coarse aggregate high-purity quartz sand (with a particle size of 0.5mm-5mm) and fine powder high-purity quartz sand (with a particle size of less than 0.5mm) in a mass ratio of 1:2 ), after being dissolved in water, zirconia balls and silicon nitride balls were added as grinding media, and ground in a vertical ball mill to obtain quartz slurry with a solid content of 94%. Add methacrylamide, diisocyanate, azobisisobutyronitrile, azobisisoheptanonitrile, N,N,N,N-tetramethylethylenediamine and polyacrylate to the above quartz slurry, mix well Obtain mixed slurry, wherein, the mass proportion of methacrylamide is 0.5%, the mass proportion of diisocyanate is 3% of methacrylamide quality, the mass proportion of azobisisobutyronitrile is 0.5%, even The mass proportion of nitrogen diisoheptanonitrile is 0.5%, the mas...

Embodiment 3

[0102] A method for preparing a composite structure quartz ceramic crucible, comprising:

[0103] Take high-purity quartz sand with a purity of 99.9%, add water, grind it fully in a ball mill or a mixer, add organic polymer monomers, cross-linking agents and initiators, and prepare a crucible body in a crucible mold by using a coagulation injection process.

[0104] Take high-purity quartz sand with a purity of 99.999%, which consists of the following particles with different particle sizes in proportion by mass: 25% high-purity quartz sand with a particle size greater than 2mm and no more than 5mm, 10% high-purity quartz sand with a particle size of 1mm-2mm Quartz sand, 15% high-purity quartz sand with a particle size not less than 0.5mm and less than 1mm, 5% high-purity quartz sand with a particle size greater than 0.1mm and less than 0.5mm, 25% high-purity quartz sand with a particle size of 0.05mm-0.1mm Sand, 20% high-purity quartz sand with a particle size of less than 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com