Double-shell insulation coating method of a metal soft magnetic composite material

A composite material and metal soft magnetic technology, applied in the direction of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problem of low heat resistance temperature of insulating film, reduce core loss and improve thermal stability , the effect of increasing the compact density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

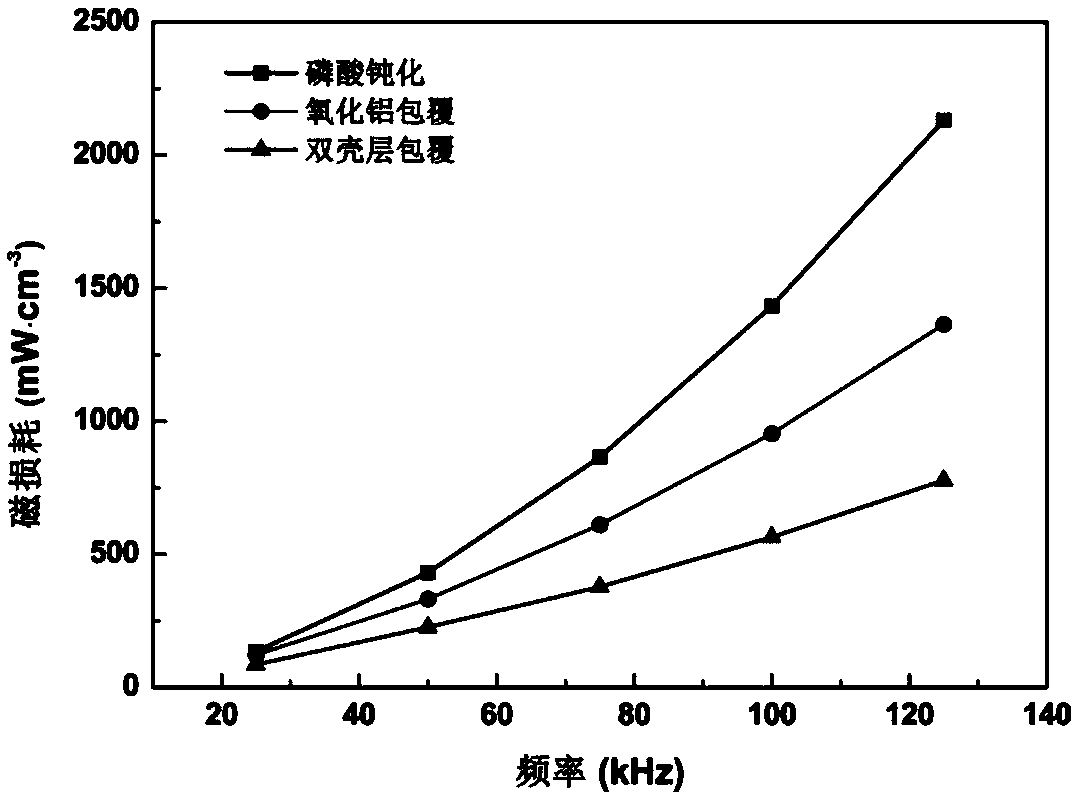

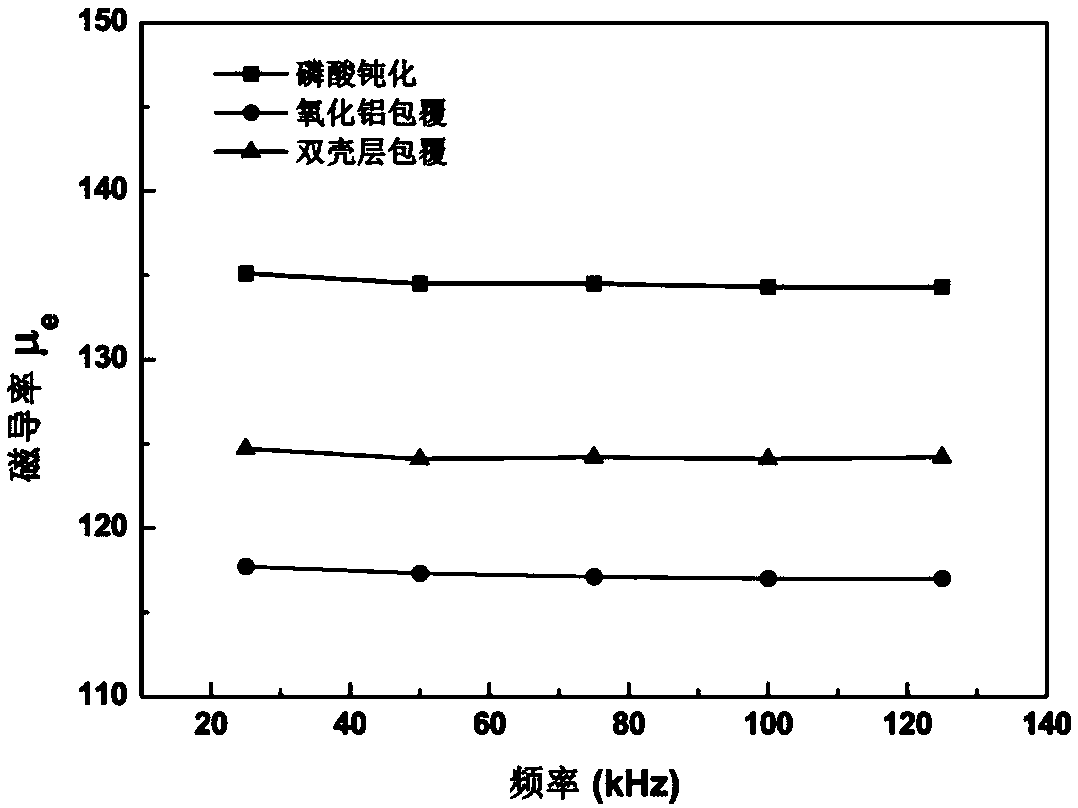

Embodiment 1

[0021] Take 15g of iron powder (i.e. metal magnetic powder), of which the iron powder with a particle size of -200 ~ +300 mesh accounts for 60% of the total mass, the iron powder of -300 ~ +400 mesh accounts for 30% of the total mass, and the iron powder above 400 mesh accounts for 10% of the total mass. Passivate the proportioned iron powder with phosphoric acid, stir and dry it in a water bath at 60° C. to obtain passivated magnetic powder, and the mass of phosphoric acid accounts for 0.5% of the total weight of the iron powder. Use the sol-gel method to insulate and coat the passivated magnetic powder, dissolve 6g of aluminum isopropoxide in 40g of absolute ethanol, drop nitric acid to adjust the pH value of the solution to 6, stir evenly for 50min to obtain a sol, take 10mL of the sol and add it to the passivation In the melted magnetic powder, mix and stir for 10 minutes to obtain a suspension. Add 2 mL of deionized water dropwise, and stir in a water bath at 50°C until ...

Embodiment 2

[0028] Take 20g of sendust powder, in which the magnetic powder with a particle size of -200~+300 mesh accounts for 50% of the total mass, the magnetic powder with a particle size of -300~+400 mesh accounts for 40% of the total mass, and the magnetic powder above 400 mesh accounts for 10% of the total mass. The proportioned sendust aluminum powder is passivated by chromic acid, stirred and dried in a water bath at 50° C. to obtain passivated magnetic powder, and the mass of chromic acid accounts for 0.8% of the total weight of the magnetic powder. Use the sol-gel method to insulate and coat the passivated magnetic powder, dissolve 4g of aluminum isopropoxide in 30g of absolute ethanol, drop nitric acid to adjust the pH value of the solution to 4, stir evenly for 30min to obtain a sol, take 25mL of the sol and add it to the passivation In the melted magnetic powder, after mixing and stirring for 20 min to obtain a suspension, 4 mL of deionized water was added dropwise, and stirr...

Embodiment 3

[0036]Take 10g of iron-nickel powder, wherein the magnetic powder with particle size of -200~+300 mesh accounts for 70% of the total mass, the magnetic powder of -300~+400 mesh accounts for 25% of the total mass, and the magnetic powder above 400 mesh accounts for 5% of the total mass. Passivate the proportioned iron-nickel powder with phosphoric acid, stir and dry it in a water bath at 80° C. to obtain passivated magnetic powder, and the mass of phosphoric acid accounts for 1.0% of the total weight of the magnetic powder. Use the sol-gel method to insulate and coat the passivated magnetic powder, dissolve 3g of aluminum isopropoxide in 25g of absolute ethanol, drop in nitric acid to adjust the pH value of the solution to 5, stir evenly for 20min to obtain a sol, take 15mL of the sol and add it to the passivation In the melted magnetic powder, mix and stir for 15 minutes to obtain a suspension. Add 3 mL of deionized water dropwise, and stir in a water bath at 60°C until comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com