A pretreatment system and method for semi-coke wastewater

A technology for charcoal wastewater and pretreatment, applied in natural water treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as poor drug reaction effect, environmental pollution, and low method efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In order to overcome the problems existing in the current semi-coke wastewater pretreatment process, the present invention provides a semi-coke high-concentration organic wastewater resource pretreatment system with high-efficiency separation system, reliable operation, stable operation and no pollutant generation.

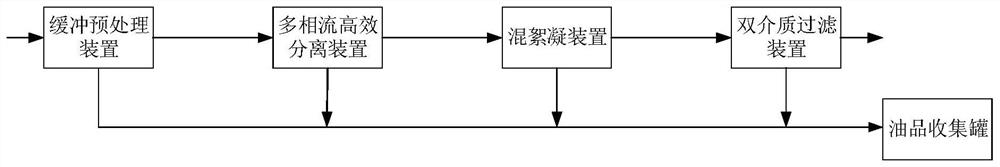

[0053] Specifically as figure 1 as shown, figure 1 Schematic diagram of the structure of the semi-coke wastewater pretreatment system provided for this embodiment; this embodiment provides a semi-coke wastewater pretreatment system, including a buffer pretreatment device connected in sequence, a multiphase flow high-efficiency separation device, a coagulation device and a double Media filtration device, wherein, the input end of the buffer pretreatment device is connected with the semi-coke wastewater output pipe, and the semi-coke wastewater first enters the buffer pretreatment device. Under the action of gravity, heavy oil and sludge deposit, and light o...

Embodiment 2

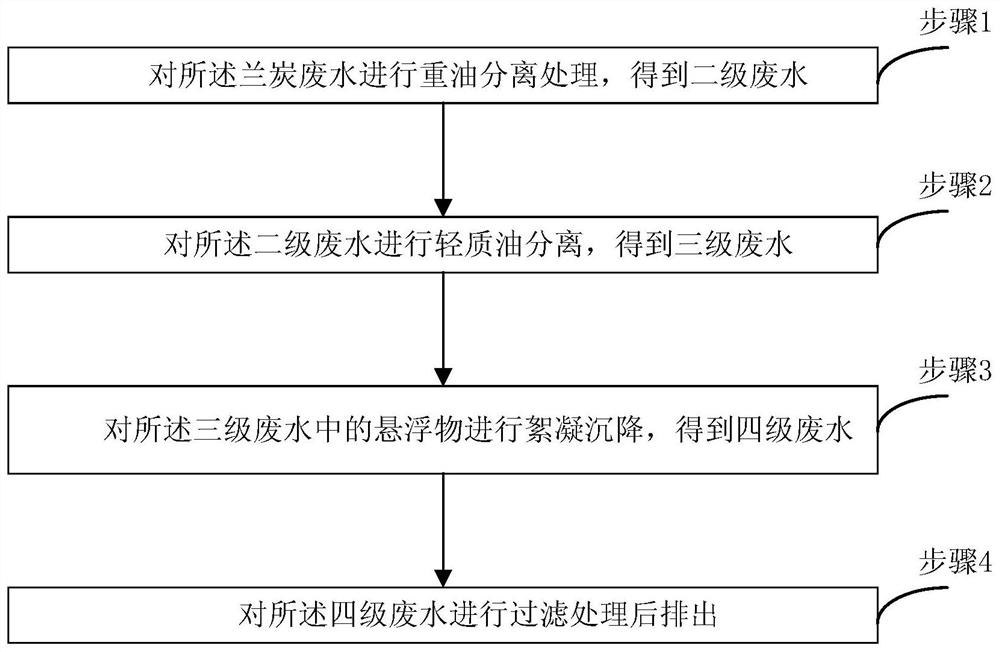

[0080] On the basis of the above-mentioned embodiments, the embodiment of the present invention utilizes the buffer pretreatment device, the multiphase flow high-efficiency separation device, the coagulation device and the dual-media filter device connected in sequence in the first embodiment to carry out the pretreatment method for the semi-coke wastewater, specifically The implementation process is as figure 2 as shown, figure 2 It is a flow chart of the semi-carbon wastewater pretreatment method provided in this embodiment. This blue charcoal wastewater pretreatment method comprises the following steps:

[0081] Step 1: Separating heavy oil from the semi-coke wastewater to obtain secondary wastewater; specifically, adding a demulsifier to the semi-coke wastewater using a static mixer; adding the demulsifier to the semi-coke wastewater in the buffer Stand still in the pretreatment device for N hours to separate the heavy oil and water, the heavy oil enters the oil produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com