Varnish primer without whitening at high temperature and high humidity and preparation method thereof

A high-temperature, high-humidity, clear primer technology, applied in the field of coatings, can solve the problems of poor wetting and penetration, affecting the appearance of furniture, leaks, etc., and achieve high hardness, good leveling and fullness, and good wetting penetration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

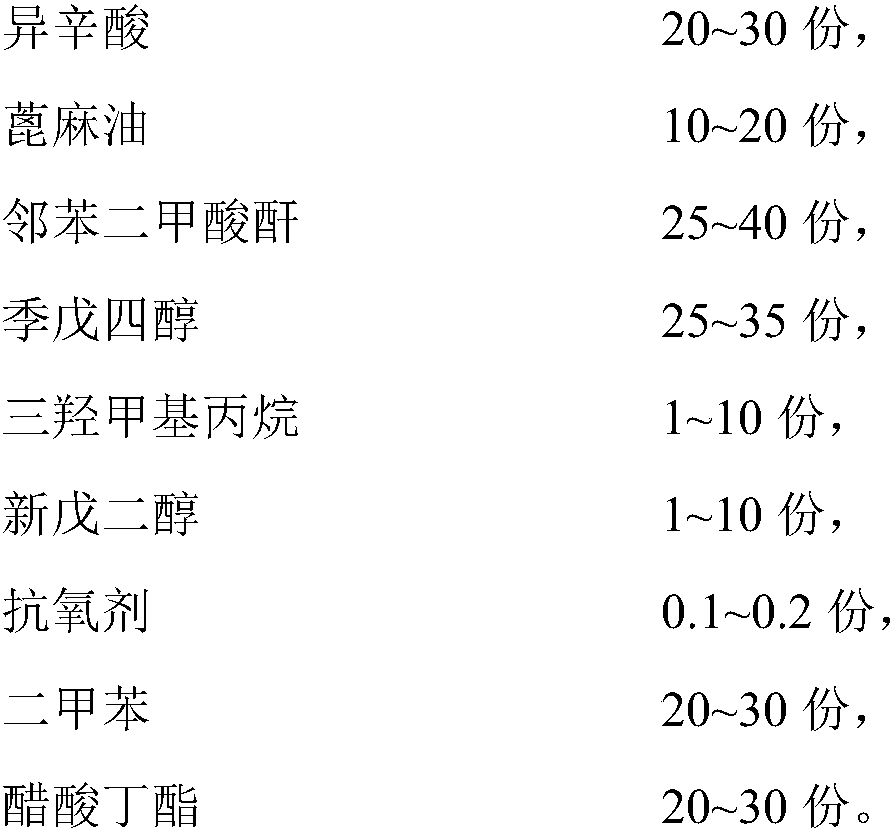

[0045] 2, the preparation method of vegetable oil fatty acid alkyd resin

[0046] The preparation method of described vegetable oil fatty acid alkyd resin comprises the steps:

[0047] 1), take each raw material component by formula quantity;

[0048] 2) Put isooctanoic acid, castor oil, phthalic anhydride, pentaerythritol, trimethylolpropane, neopentyl glycol, antioxidant hypophosphorous acid and 5 kg of xylene into the reactor in sequence, and heat up to 150-160°C Keep warm for 1-1.5 hours, then rise to 220-225°C and keep warm until the test passes: viscosity 10000-20000mPa.s, solid content: 60-65% by weight, acid value: ≤15mgKOH / g, cool down to 160-170 It can be obtained by diluting butyl acetate with the remaining xylene at ℃.

Embodiment 1

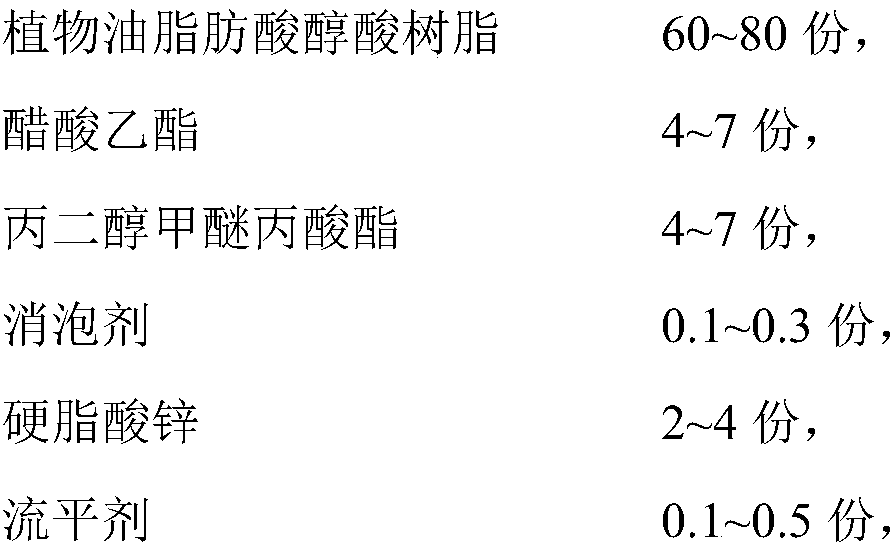

[0051] 1. The formula and preparation method of the main agent of polyurethane varnish

[0052] formula

[0053] The formula of the polyurethane varnish main agent is as follows: 77 kilograms of vegetable oil fatty acid alkyd resin, 6 kilograms of ethyl acetate, 6 kilograms of propylene glycol methyl ether propionate, BYK163 high molecular weight block copolymer solution dispersant containing pigment affinity group 1.5 kg, BYK141 polysiloxane solution defoamer 0.2 kg, Disparon's 4200-10 polyethylene wax slurry anti-settling agent 2.5 kg, Guangxi Guiguang 1250 mesh talcum powder 2 kg, Sanyi SAK-ZS-PLB Zinc stearate 3.5 kg, BYK-333 polyether modified polydimethylsiloxane copolymer leveling agent 0.1 kg, ethylene glycol monobutyl ether 1 kg.

[0054] Preparation

[0055]The preparation method of described polyurethane varnish main agent comprises the steps:

[0056] 1), weigh each raw material component according to formula.

[0057] 2) Put the vegetable oil fatty acid a...

Embodiment 2

[0071] 1. The formula and preparation method of the main agent of polyurethane varnish

[0072] formula

[0073] The formula of the polyurethane varnish main agent is as follows: 75 kilograms of vegetable oil fatty acid alkyd resin, 4.5 kilograms of ethyl acetate, 5.5 kilograms of propylene glycol methyl ether propionate, BYK163 high molecular weight block copolymer solution dispersant containing pigment affinity group 2 kg, BYK141 polysiloxane solution defoamer 0.3 kg, 4200-10 polyethylene wax anti-settling agent 2 kg, 1250 mesh talcum powder 4.5 kg, Sanyi SAK-ZS-PLB zinc stearate 4 kg, BYK- 0.2 kg of 333 polyether modified polydimethylsiloxane copolymer leveling agent, 2 kg of ethylene glycol monobutyl ether.

[0074] Preparation

[0075] 1), weigh each raw material component according to formula.

[0076] 2) Put the vegetable oil fatty acid alkyd resin, ethyl acetate, and propylene glycol methyl ether propionate in the components into the dispersing tank, and disperse wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com