Aluminosilicate glass, preparation method thereof, electronic display screen protection glass

A technology of aluminosilicate glass and protective glass, which is applied to the glass plate of the aluminosilicate glass material and the preparation field of aluminosilicate reinforced glass, can solve the problem of poor thermal shock resistance of glass and 3D thermal shock of glass annealing. The problems of increased bending forming and difficulty in homogenization can achieve the effect of good thermal shock resistance and fast ion exchange speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0053] According to the above-mentioned aluminosilicate glass formula, calculate the amount of corresponding raw materials and weigh them. After fully mixing in a mixer, put them into a platinum crucible, and perform melting and clarification in a high-temperature furnace at 1630°C for 6 hours. The molten glass is poured into a graphite mold for molding, and kept at 600°C for half an hour, and then cooled in the furnace to obtain a glass block. After mechanical cutting, rough grinding, fine grinding, and polishing, it becomes a sheet glass with a thickness of 1.1 mm.

specific Embodiment

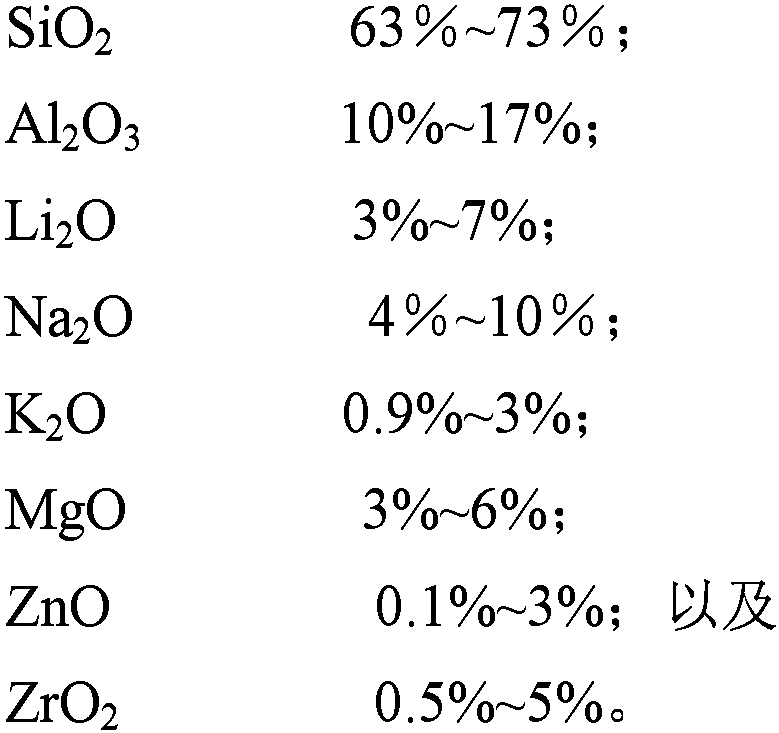

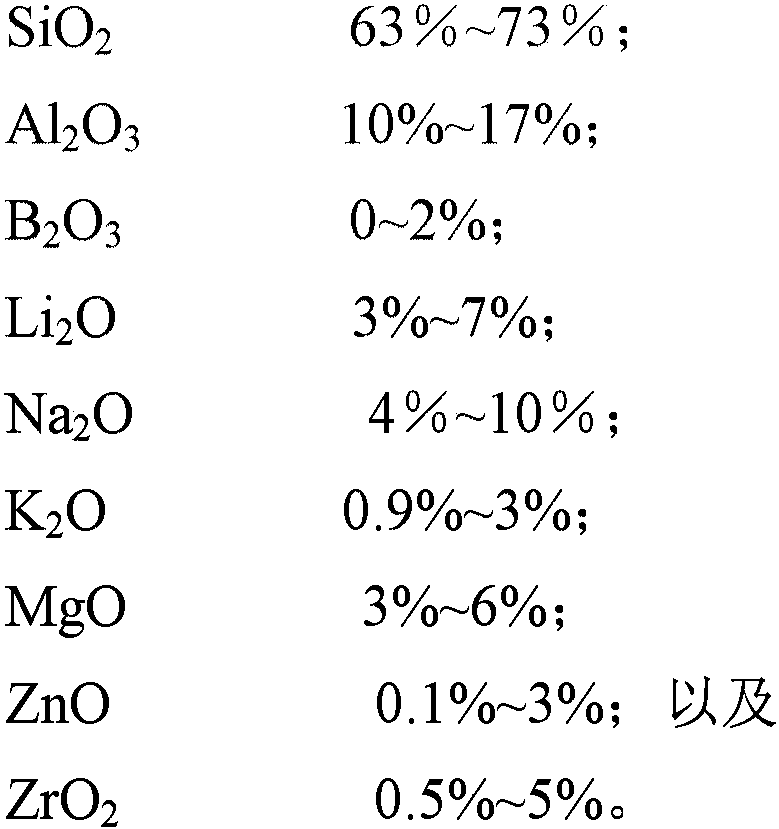

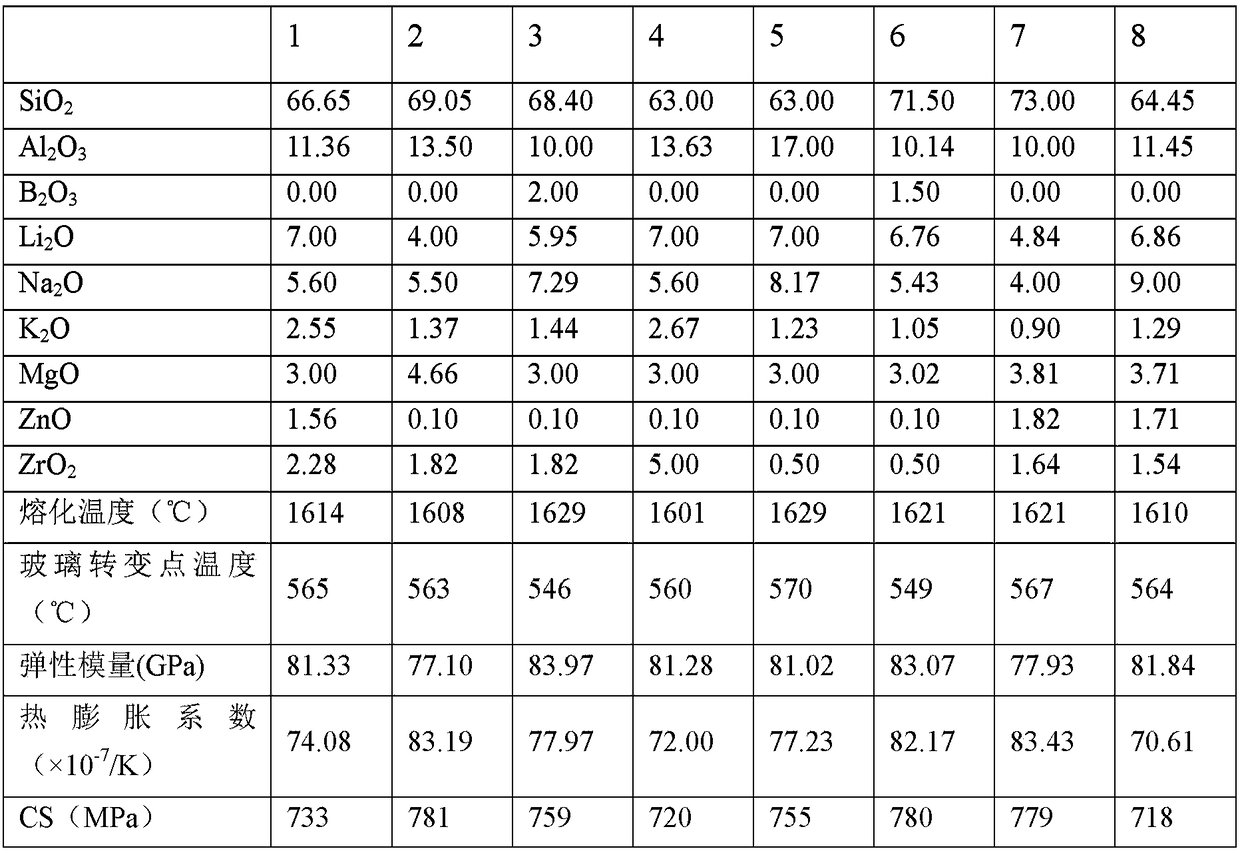

[0054] Table 1, Table 2 and Table 3 respectively list the composition of No. 1-24 glasses and the corresponding melting temperature of the glass (the viscosity of glass liquid is 10 2dPa·s), glass transition temperature, elastic modulus, thermal expansion coefficient, and strengthening properties measured under special ion exchange process conditions. Among them, the melting temperature is measured by the glass high temperature rotational viscosity measuring instrument model ZH9866; the elastic modulus of the glass is measured by the WH-ki elastic modulus measuring instrument; the glass transition point temperature and thermal expansion coefficient are measured by the model NETZSCH DIL 402 The thermal dilatometer of Expedis Classic is used for measurement; the glass surface compressive stress (CS) and the glass stress layer depth (DOC) are the results of the joint test of the scattering photoelasticity analyzer SLP and FSM-6000LE. Nos. 1-20 are examples of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com