Method for adsorption separation of propylene, propyne, propane and propadiene

A technology of propadiene and propyne is applied in the field of adsorption and separation of propylene, propyne, propane and propadiene, which can solve the problems of poor hydrothermal stability, high preparation cost and high ligand price, and achieve stable performance and high performance. Adsorption selectivity, effect of simple purification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

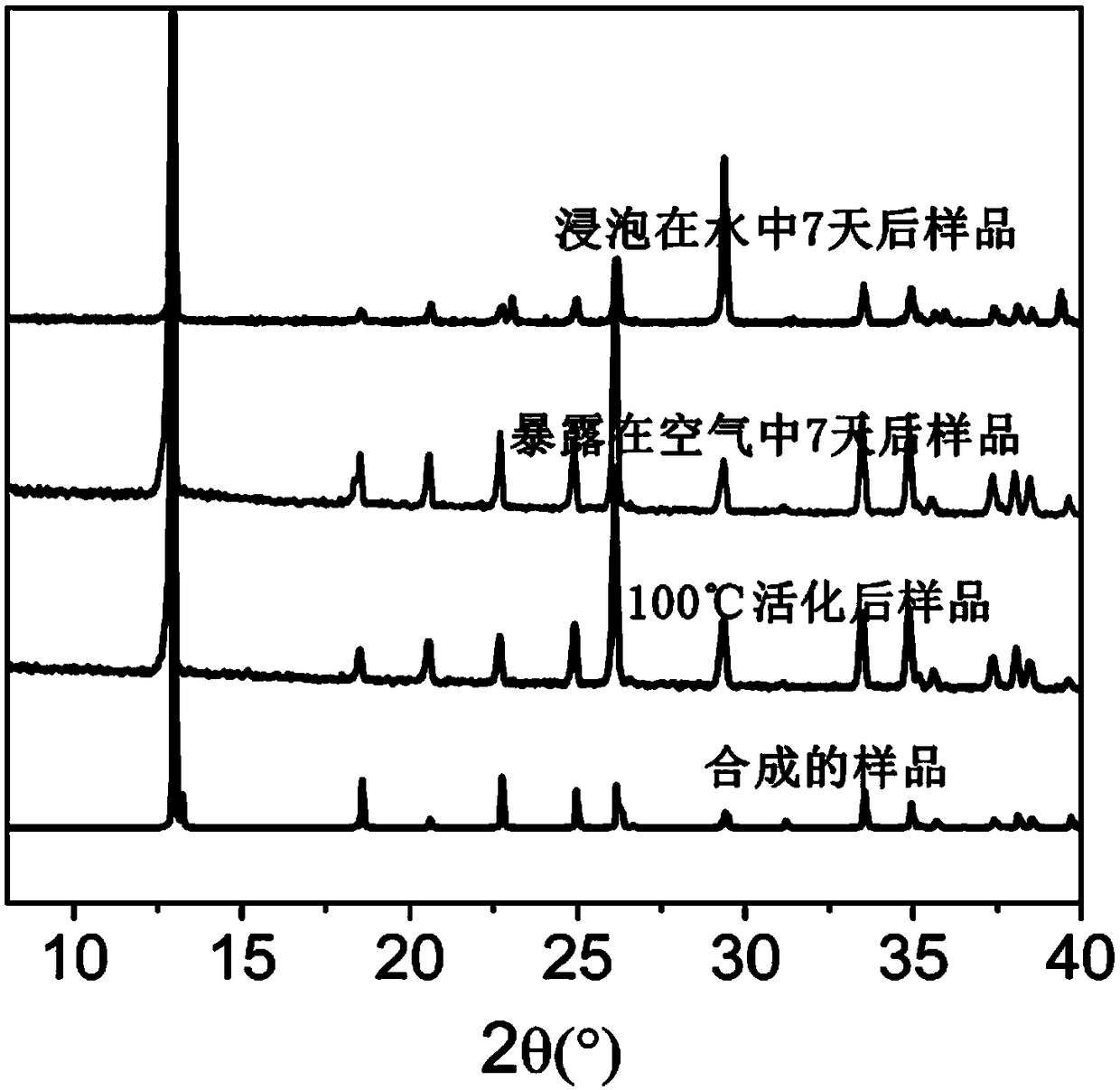

[0038] Mix 0.151mmol calcium carbonate, 0.151mmol squaraine, and 20mL deionized water, put them into a 25mL hydrothermal reaction kettle, stir for 30 minutes, and react at 120°C for 24 hours. After the reaction is completed, the reactor is cooled, and washed with pure water for several times to obtain a purified metal organic framework material. The purified adsorbent was vacuum degassed at 100 °C for 12 h to obtain the desolvated adsorbent, followed by gas adsorption.

[0039] Single-component adsorption isotherms for propene, propyne, propane, and allene were performed using the above adsorbents. Take an appropriate amount of adsorbent, and the adsorption temperature is 0 degrees and 25 degrees. At 0°C and 1 bar, the adsorption capacity of propylene reaches 2.9mmol / g, the adsorption capacity of propyne is 3.3mmol / g, the adsorption capacity of propane is 2.7mmol / g, and the adsorption capacity of propadiene is 3.5mmol / g. This system is at 0°C and 0.01bar; the adsorption capa...

Embodiment 2

[0042] Mix 1.93mmol cobalt chloride hexahydrate, 2.88mmol squaraine, 7.72mmol potassium hydroxide, and 7ml deionized water, put them into a 25mL hydrothermal reactor, stir for 30 minutes, and then heat to 220°C for 48 hours. After the reaction is completed, the reactor is cooled, and the solid obtained from the reaction is washed with pure water several times to obtain a purified metal-organic framework material. The purified adsorbent was vacuum degassed at 120 °C for 12 h to obtain the desolvated adsorbent, followed by gas adsorption.

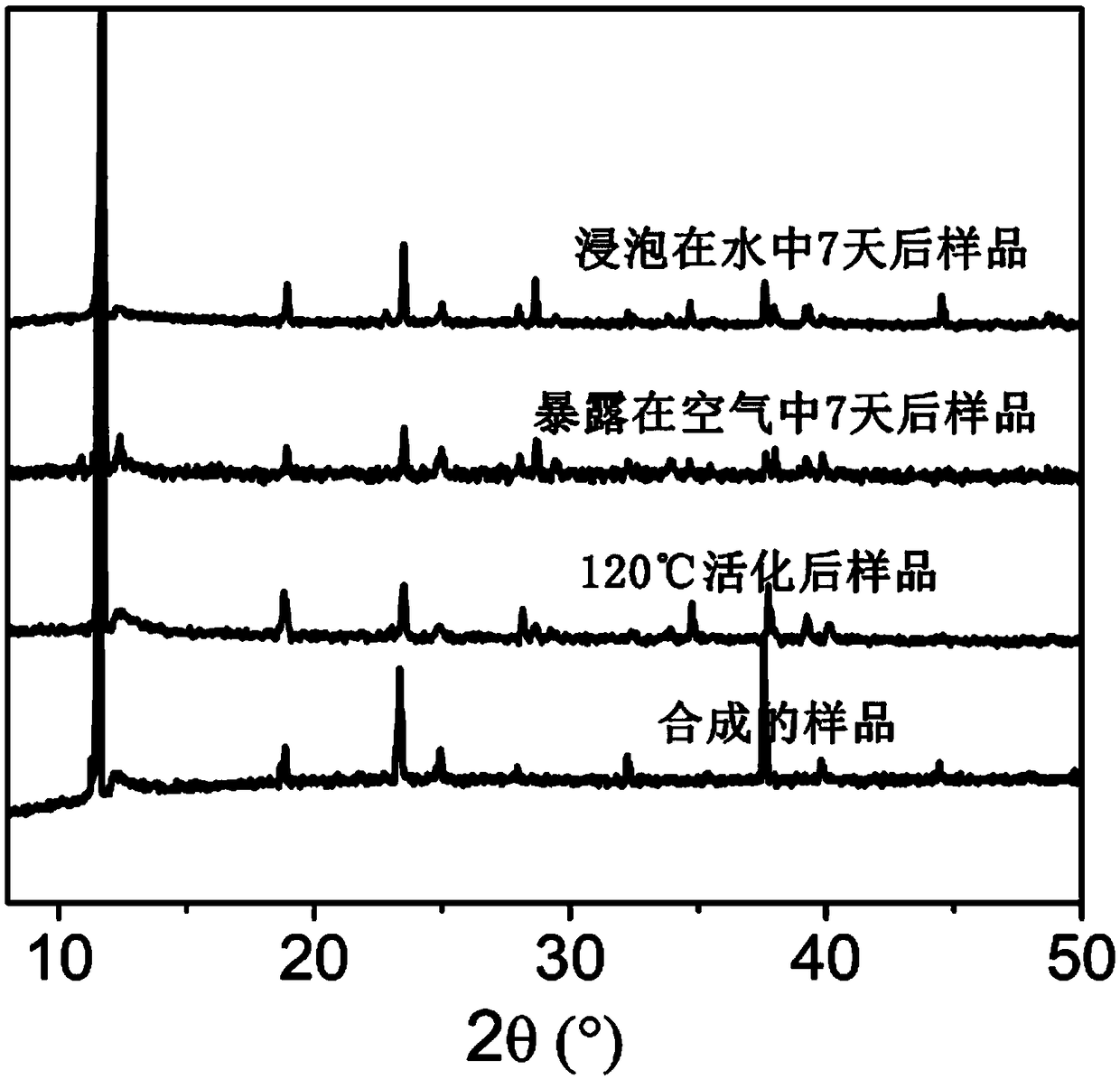

[0043] In order to test the stability of the samples, the samples were exposed to air with a relative humidity of 60% for 7 days and soaked in pure water for 7 days, and then XRD measurements were performed on the samples under various conditions. XRD curve see figure 2 . From the results, whether soaked in water for 7 days or exposed to air with a relative humidity of 60% for 7 days, the XRD of the adsorbent is consistent with that just s...

Embodiment 3

[0045] Mix 1.93mmol nickel chloride hexahydrate, 2.88mmol squaraine, 7.72mmol potassium hydroxide, and 7mL deionized water, put them into a 25mL hydrothermal reactor, stir for 30 minutes, and react at 220°C for 48 hours. After the reaction is completed, it is cooled and washed with pure water several times to obtain a purified metal-organic framework material. The purified adsorbent was vacuum degassed at 120 °C for 12 hours to obtain the desolvated adsorbent, followed by gas adsorption.

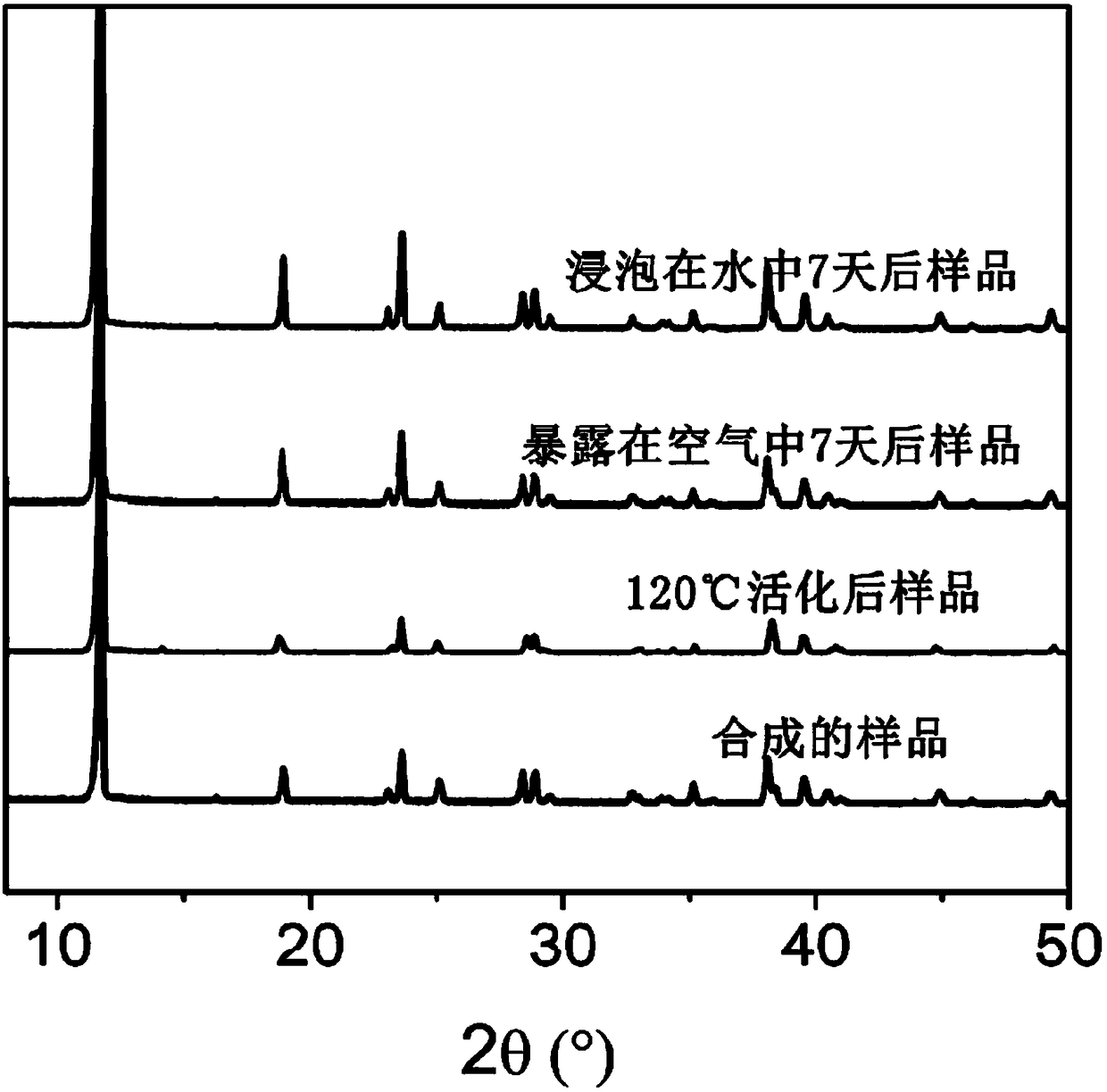

[0046] In order to test the stability of the sample, the sample was exposed to air with a relative humidity of 60% for 7 days and soaked in pure water for 7 days, and then the XRD determination of the adsorbent under each condition was carried out. XRD curve see image 3 . From the results, whether soaked in water for 7 days or exposed to air with a relative humidity of 60% for 7 days, the XRD of the adsorbent is consistent with that just synthesized, indicating the excellent stability of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com