Continuous production method of high-purity lactose

A production method and high-purity technology, applied in the field of continuous production of high-purity lactose, can solve the problems of lactose application limitations, adverse reactions, etc., and achieve the effect of simple and feasible production method, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

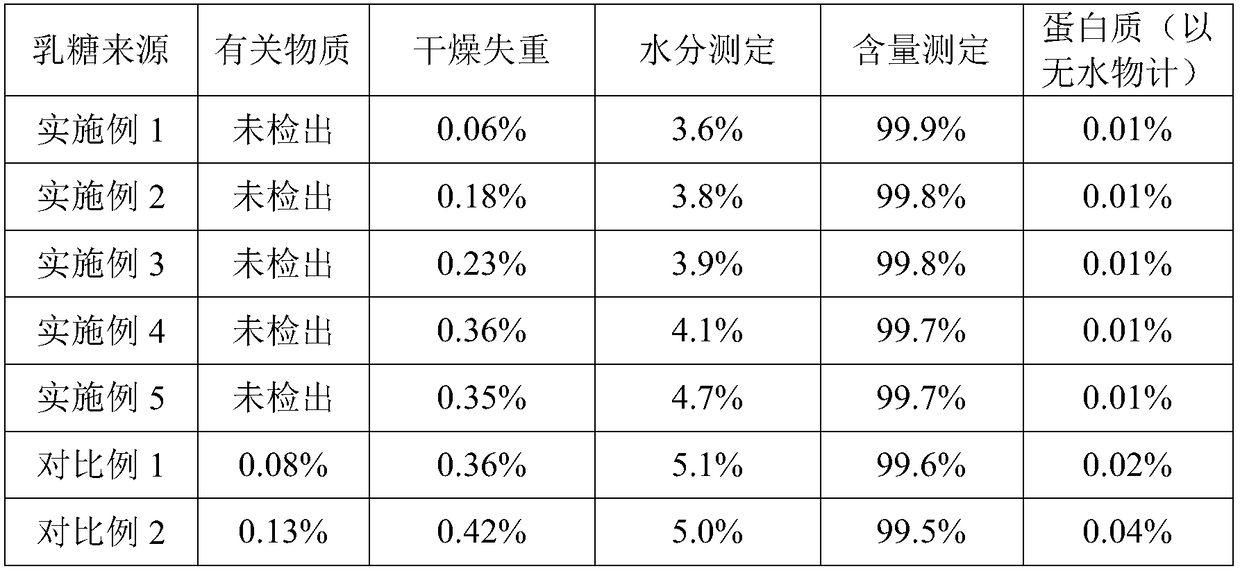

Examples

Embodiment 1

[0024] A kind of continuous production method of high-purity lactose provided by the present embodiment comprises the following steps:

[0025] (1) Mix crude lactose and purified water at a weight ratio of 1:8, stir and heat to 35°C to make a lactose solution, and then mix the lactose solution with the adsorbent (attapulgite-rice bran cellulose composite adsorption microspheres) according to 3.5 : the weight ratio of 100 is mixed, heated and boiled for 45min to obtain a mixed solution;

[0026] (2) Cool the mixture of crude lactose and adsorbent prepared in step (1) to 35°C and press filter to obtain a pure lactose solution, and then pass through the ultrafiltration device in sequence (the set pressure difference is 0.2MPa) , nanofiltration device (setting differential pressure is 0.7MPa) filtration, obtains the filter residue that intercepts;

[0027] (3) Mix the filter residue and purified water prepared in step (2) according to the weight ratio of 1:1.2, stir and heat to 8...

Embodiment 2

[0031] A kind of continuous production method of high-purity lactose provided by the present embodiment comprises the following steps:

[0032] (1) Mix crude lactose and purified water in a weight ratio of 1:5, stir and heat to 30°C to make a lactose solution, and then mix the lactose solution with the adsorbent (attapulgite-rice bran cellulose composite adsorption microspheres) according to 1 : the weight ratio of 100 is mixed, heated and boiled for 30min to obtain a mixed solution;

[0033] (2) Cool the mixture of crude lactose and adsorbent prepared in step (1) to 30°C and press filter to obtain a pure lactose solution, and then pass through the ultrafiltration device in sequence (the set pressure difference is 0.1MPa) , nanofiltration device (setting differential pressure is 0.6MPa) filtration, obtains the filter residue that intercepts;

[0034] (3) Mix the filter residue and purified water prepared in step (2) according to the weight ratio of 1:1, stir and heat to 80°C ...

Embodiment 3

[0038] A kind of continuous production method of high-purity lactose provided by the present embodiment comprises the following steps:

[0039] (1) After mixing crude lactose and purified water at a weight ratio of 1:10, stir and heat to 45°C to make a lactose solution, and then mix the lactose solution with the adsorbent (attapulgite-rice bran cellulose composite adsorption microspheres) according to 1 : mixed in a weight ratio of 100, heated and boiled for 30 to 60 minutes to obtain a mixed solution;

[0040] (2) Cool the mixture of crude lactose and adsorbent prepared in step (1) to 30°C and press filter to obtain a pure lactose solution, and then pass through the ultrafiltration device in sequence (the set pressure difference is 0.1MPa) , nanofiltration device (setting differential pressure is 0.6MPa) filtration, obtains the filter residue that intercepts;

[0041] (3) Mix the filter residue and purified water prepared in step (2) according to the weight ratio of 1:1.5, s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap