Preparation method and application of micro-porous polymer

A microporous polymer, tri-indene technology, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc. Weak physical adsorption and other problems, to achieve the effect of good planarity, easy synthesis and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 A kind of preparation method of polymer P-C-H

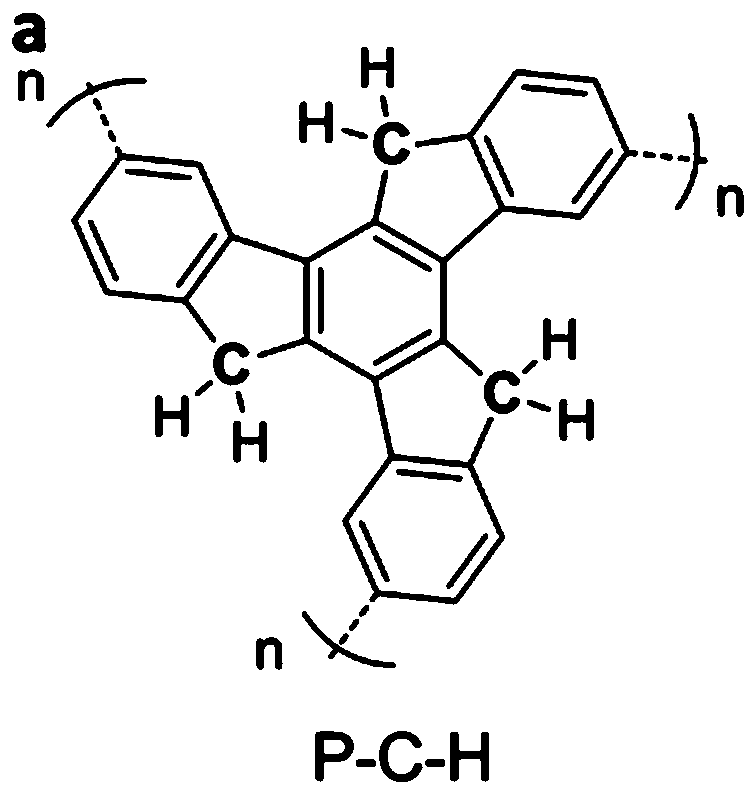

[0050] The polymer P-C-H structural formula of the present embodiment is as Figure 1a As shown, its synthetic route is:

[0051]

[0052] The synthetic method of the present embodiment is carried out according to the following steps:

[0053] 1) Synthesis of monomer triindene

[0054] Mix 1kg of 1-indanone, 5L of 30% HCl and 20L of 6mol / L HOAc, under the protection of an inert gas, heat up to 60°C with electromagnetic stirring, stop heating after 3 hours of reaction, and cool down to room temperature Pour into 30 L of ice water and stir for 0.5 h, filter to obtain an off-white solid D1, and recrystallize the off-white solid D1 with 100 L of toluene to obtain 380 g of bright yellow triacinene powder with a yield of 50%.

[0055] 2) Synthesis of polymer P-C-H

[0056] Add 40mmol monomer trisindene, 3L of CaH 2 Dry chloroform and 282mmol anhydrous ferric chloride, and pass nitrogen gas to make the pressur...

Embodiment 2-7

[0058] The preparation method of embodiment 2-7 polymer P-C-H

[0059] Examples 2-7 are respectively a preparation method of a polymer P-C-H, wherein the polymer P-C-H structural formula and synthetic route are the same as those in Example 1, and the only difference between them and Example 1 is that the technical parameters of the synthesis process are different. For details, see Table 1:

[0060] Table 1

[0061]

[0062]

Embodiment 8

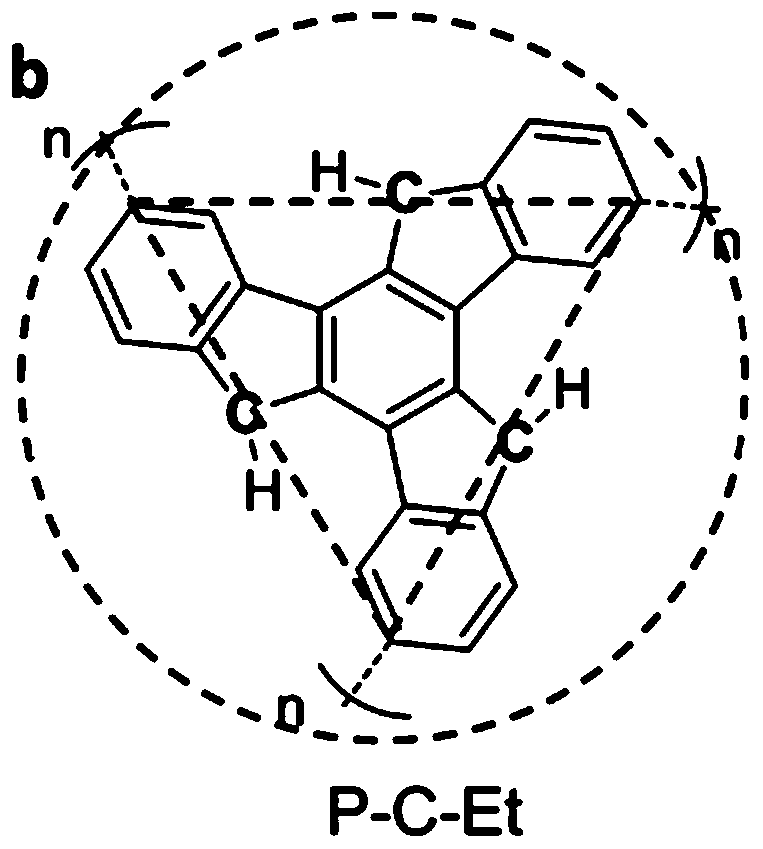

[0063] Embodiment 8 A kind of preparation method of polymer P-C-Et

[0064] The polymer P-C-Et structural formula of the present embodiment is as Figure 1b As shown, its synthetic route is:

[0065]

[0066] This embodiment is carried out in the following steps:

[0067] 1) Synthesis of tripolyindene

[0068] The synthesis of trisindene is synthesized according to the synthetic method of step 1) monomer trisindene of any embodiment in the embodiment 1-7.

[0069] 2) Synthesis of monomer 5,10,15-triethyltriindene

[0070] Under anhydrous and oxygen-free conditions, mix 10L tetrahydrofuran dehydrated by sodium tablets with 410g trisindene, stir to form a suspension, then slowly add 1.4L n-butyllithium 2.8M n-hexane solution under ice-water bath conditions, After reacting for 0.5h, react at room temperature for another 0.5h. Then use an ice-salt bath to cool down to -10°C, then slowly add 620 mL of bromoethane with a syringe, stir and react at room temperature for 4 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com