Preparation method of self-supporting double carbon structure compounding Ga2O3 lithium ion battery anode

A lithium-ion battery and carbon structure technology, applied in the field of electrochemical power supply, can solve problems such as unreported, and achieve the effects of good repeatability, good conductivity and flexibility, and simple and controllable preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

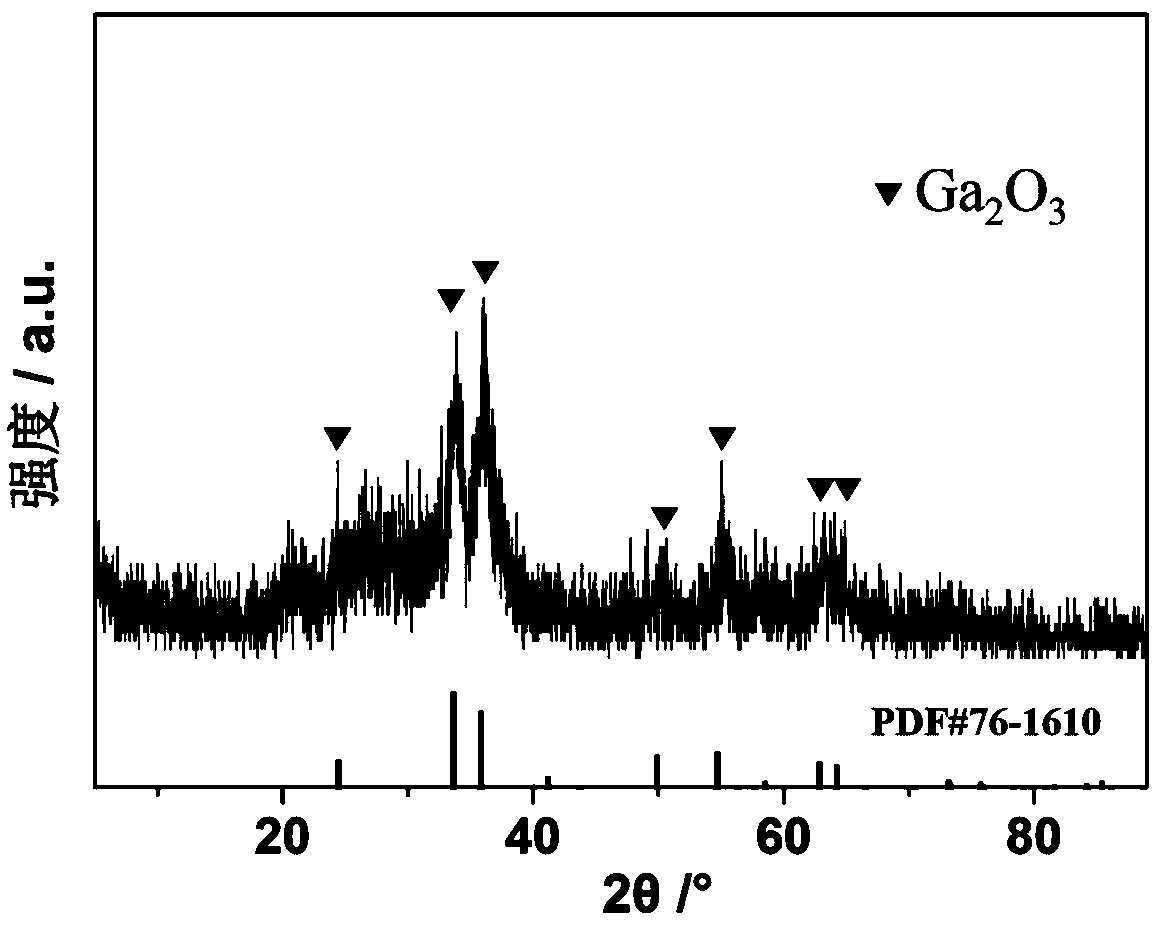

[0028] Weigh 0.5g of polyvinyl butyral and dissolve it in 10ml of ethanol, stir at a constant temperature of 60°C until a uniform colloidal solution is formed, and cool to room temperature; weigh 1.024g of gallium nitrate, 0.7009g of hexamethylenetetramine In the above colloidal solution, stir until completely dissolved to form a precursor solution; put the precursor solution into a plastic syringe, carry out the electrospinning process, use the tinfoil on the drum receiver to collect the fiber bundles, and the drum receiver The distance from the needle is 13cm, the working voltage range and the solution advancing rate are set to 9.8kV, 0.4mm min -1 ; The collected fiber bundles were dried in an oven at 70°C and then sintered in a tube furnace at 550°C under nitrogen for 5 hours to obtain carbon composite Ga grown on the surface of C fibers 2 o 3 Composite structure. The samples were characterized by XRD, such as figure 1 As shown, Ga 2 o 3 (XRD card JCPDS, NO. 85-0988) h...

Embodiment 2

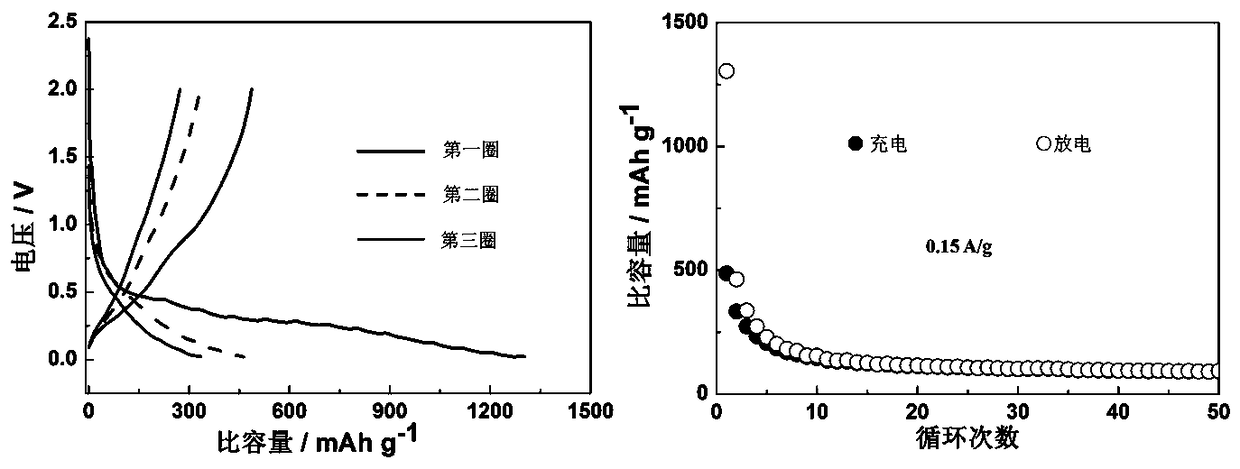

[0030] Weigh 0.5g of polyvinyl butyral and dissolve it in 10ml of ethanol, stir at a constant temperature of 60°C until a uniform colloidal solution is formed, and cool to room temperature; weigh 1.024g of gallium nitrate, 0.7009g of hexamethylenetetramine In the above colloidal solution, stir until completely dissolved to form a precursor solution; put the precursor solution into a plastic syringe, carry out the electrospinning process, use the tinfoil on the drum receiver to collect the fiber bundles, and the drum receiver The distance from the needle is 13cm, the working voltage range and the solution advancing rate are set to 9.8kV, 0.4mm min -1 ; The collected fiber bundles were dried in an oven at 70°C and then sintered in a tube furnace at 450°C under nitrogen for 5 hours to obtain carbon composite Ga grown on the surface of C fibers 2 o 3 Composite structure. The battery was assembled according to the method of Example 1. Figure 4 shows that the carbon-composite Ga2...

Embodiment 3

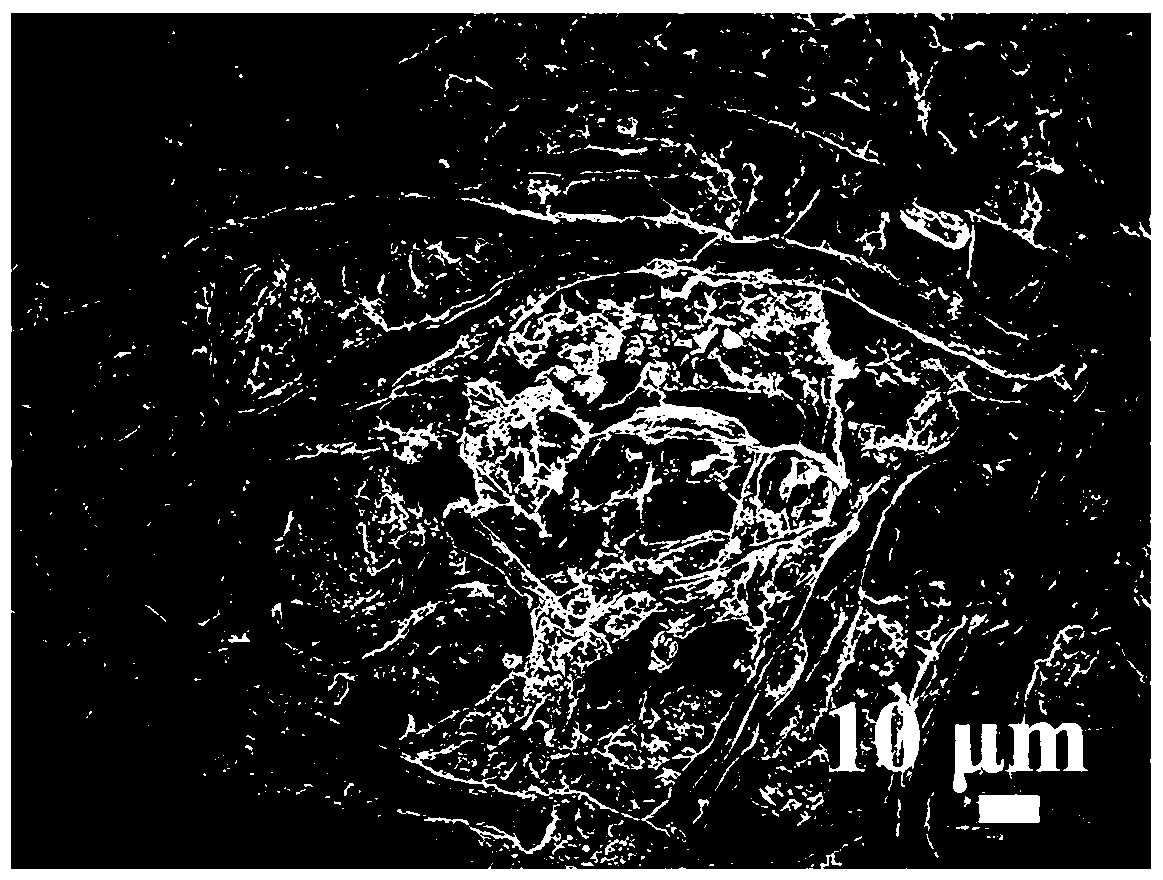

[0032] Weigh 0.5g of polyvinyl butyral and dissolve it in 10ml of ethanol, stir at a constant temperature of 60°C until a uniform colloidal solution is formed, and cool to room temperature; weigh 1.024g of gallium nitrate, 0.7009g of hexamethylenetetramine In the above colloidal solution, stir until completely dissolved to form a precursor solution; put the precursor solution into a plastic syringe, carry out the electrospinning process, use the tinfoil on the drum receiver to collect the fiber bundles, and the drum receiver The distance from the needle is 13cm, the working voltage range and the solution advancing rate are set to 9.8kV, 0.4mm min -1 ; The collected fiber bundles were dried in an oven at 70°C and then sintered in a tube furnace at 650°C under nitrogen for 5h to obtain a carbon-composite Ga2O3 composite structure grown on the surface of C fibers. The battery was assembled according to the method of Example 1. Figure 5 It shows that the surface of C fiber prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com