Perovskite-based thin film solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as device instability and restricting the large-scale application of perovskite-based thin-film solar cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention also provides a method for preparing the above-mentioned perovskite-based thin film solar cell, which includes:

[0028] S1. Deposition of TiO on the surface of conductive substrate by magnetron sputtering technique 2 Dense film, TiO after annealing 2 electron transport layer.

[0029] Conductive substrates can be cleaned prior to magnetron sputtering. The cleaning methods include: ultrasonic cleaning and drying with detergent, deionized water, ethanol, acetone, and isopropanol, and ultraviolet and ozone treatment to improve the base work function. Cleaning the conductive substrate can improve the effect of magnetron sputtering and obtain denser and stronger adhesion TiO 2 film.

[0030] Further, the temperature of the magnetron sputtering is room temperature, the sputtering power is 80-150W, the pressure is 0.4-1Pa, and the distance between the target and the conductive substrate is 10-20cm. Specifically, the cleaned conduct...

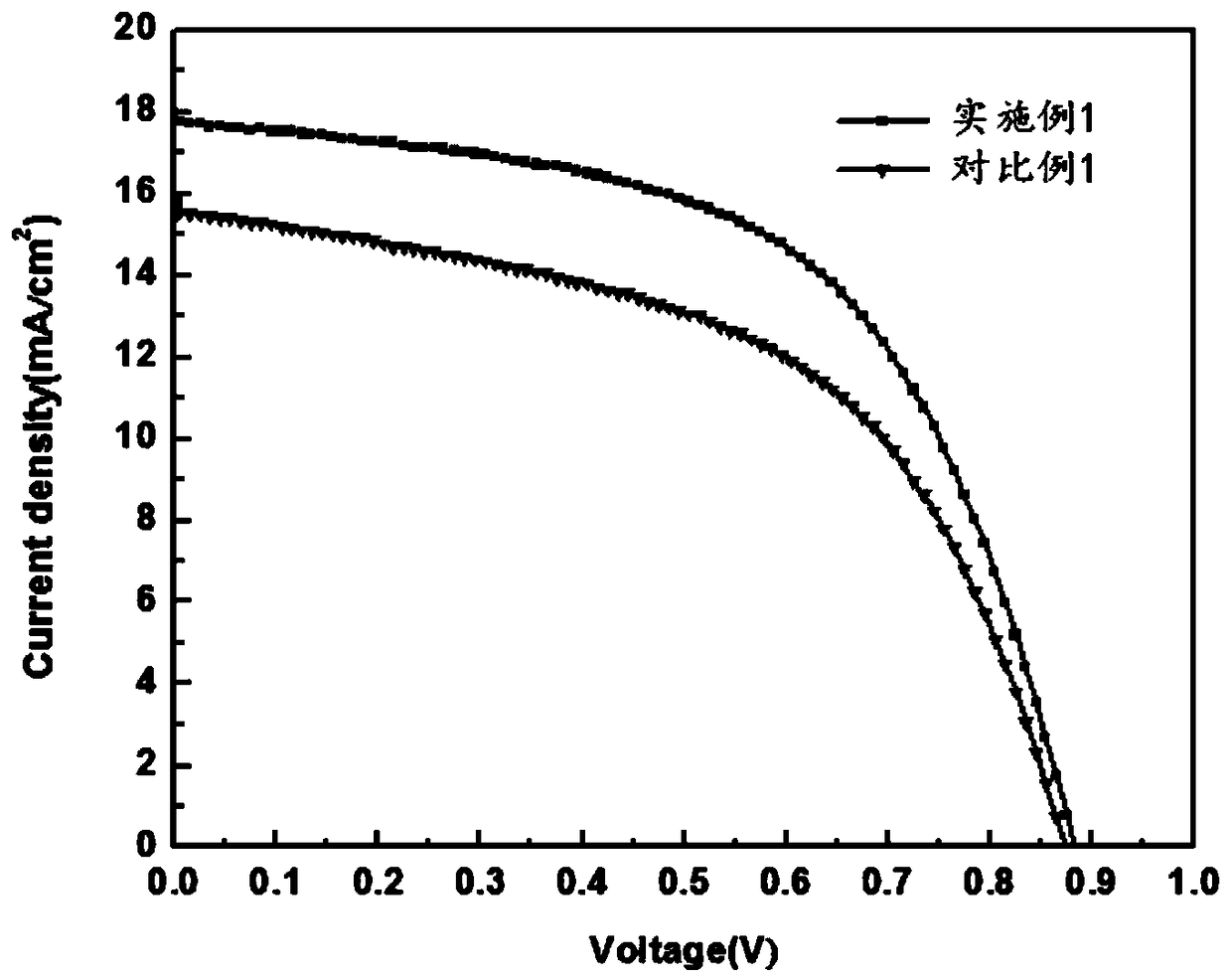

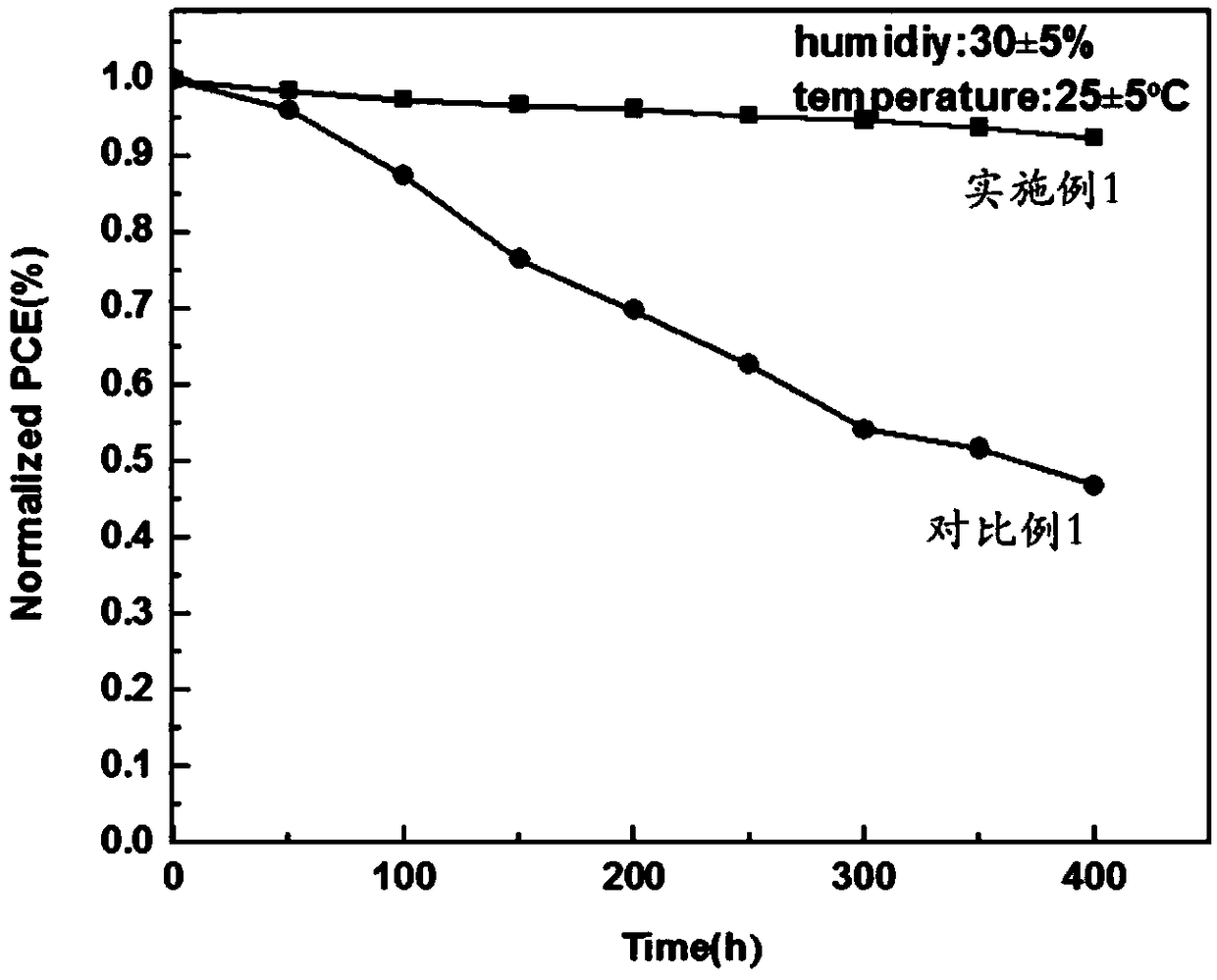

Embodiment 1

[0047] This embodiment provides a perovskite-based thin film solar cell, the preparation method of which comprises:

[0048] S1. Preparation of TiO 2 electron transport layer

[0049] S1-1. Ultrasonic cleaning and drying of the FTO glass with acetone, detergent, deionized water, ethanol, and isopropanol, and after ultraviolet and ozone treatment, put it into the magnetron sputtering chamber and close the hatch;

[0050] S1-2. Use a mechanical pump and a vacuum molecular pump to pump the sputtering chamber to 7×10 -4 Pa, through the argon control pressure is 0.8Pa. Set the sputtering power to 120W, and the rotational speed of the sample stage to 6rpm. Start the DC power supply to ignite, and pre-sputter for 5 minutes to remove pollutants;

[0051] S1-3. Open the sample plate and start sputtering, 100nm TiO can be obtained by sputtering for 30 minutes 2 dense layer thin film, the resulting TiO 2 Dense and thin annealed at 400°C for 30min to obtain TiO 2 electron transport...

Embodiment 2

[0064] This embodiment provides a perovskite-based thin film solar cell, the preparation method of which comprises:

[0065] S1. Preparation of TiO 2 electron transport layer

[0066] S1-1. Ultrasonic cleaning and drying of the ITO glass with acetone, detergent, deionized water, ethanol, and isopropanol, and after ultraviolet and ozone treatment, put it into the magnetron sputtering chamber and close the hatch;

[0067] S1-2. Use a mechanical pump and a vacuum molecular pump to pump the sputtering chamber to 8×10 -4 Pa, through the argon control pressure to 1Pa. Set the sputtering power to 100W, and the rotational speed of the sample stage to 6rpm. Start the DC power supply to ignite, and pre-sputter for 10 minutes to remove pollutants;

[0068] S1-3. Open the sample plate and start sputtering, 130nm TiO can be obtained by sputtering for 40 minutes 2 dense layer thin film, the resulting TiO 2 Dense and thin annealed at 500°C for 30min to obtain TiO 2 electron transport ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com