Phosphorus high-throughput adsorption nano-fiber membrane and preparation method thereof

A nanofiber membrane, high-throughput technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc. Hydrolysis resistance and swelling resistance, increase the surface area, and prevent the effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a phosphorus high-flux adsorption nanofiber membrane, comprising the following steps:

[0032] (1) Add PVA and PEI into deionized water at a mass ratio of 3:1, stir at 85°C until completely dissolved to obtain a PVA / PEI solution, and then add La(NO 3 ) 3 ·6H 2 O is added to the PVA / PEI solution to obtain an electrospinning solution; wherein, the total mass of PVA and PEI in the electrospinning solution is the same as La(NO 3 ) 3 The mass ratio of the electrospinning solution is 5:1, and the total content of PVA and PEI in the electrospinning solution is 8wt.%.

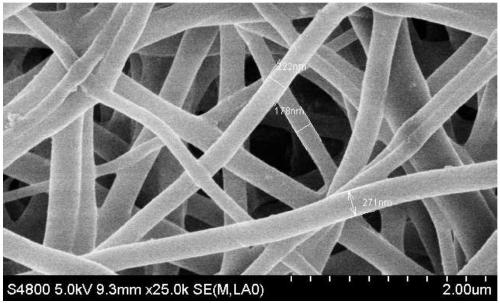

[0033] (2) The electrospinning solution obtained in step (1) is electrospun through an electrospinning device to obtain an electrospun membrane (its appearance is as follows: figure 1 Shown); Wherein, the parameter of electrospinning is: spinning voltage is 25kv, and receiving distance is 25cm; The electrospun film that obtains is collected on release paper;

[0034] (3) Place the ele...

Embodiment 2

[0040] A method for preparing a phosphorus high-flux adsorption nanofiber membrane, comprising the following steps:

[0041] (1) Add PVA and PEI into deionized water at a mass ratio of 3:1, stir at 85°C until completely dissolved to obtain a PVA / PEI solution, and then add La(NO 3 ) 3 ·6H 2 O is added to the PVA / PEI solution to obtain an electrospinning solution; wherein, the total mass of PVA and PEI in the electrospinning solution is the same as La(NO 3 ) 3 The mass ratio of the electrospinning solution is 10:1, and the total content of PVA and PEI in the electrospinning solution is 12wt.%.

[0042] (2) The electrospinning solution obtained in step (1) is electrospun through an electrospinning device to obtain an electrospun membrane (its appearance is as follows: figure 1 Shown); Wherein, the parameter of electrospinning is: spinning voltage is 25kv, and receiving distance is 25cm; The electrospun film that obtains is collected on release paper;

[0043] (3) Place the e...

Embodiment 3

[0047] A method for preparing a phosphorus high-flux adsorption nanofiber membrane, comprising the following steps:

[0048] (1) Add PVA and PEI into deionized water at a mass ratio of 3:1, stir at 85°C until completely dissolved to obtain a PVA / PEI solution, and then add La(NO 3 ) 3 ·6H 2 O is added to the PVA / PEI solution to obtain an electrospinning solution; wherein, the total mass of PVA and PEI in the electrospinning solution is the same as La(NO 3 ) 3 The mass ratio of the electrospinning solution is 1:1, and the total content of PVA and PEI in the electrospinning solution is 8wt.%.

[0049] (2) The electrospinning solution obtained in step (1) is electrospun through an electrospinning device to obtain an electrospun membrane (its appearance is as follows: figure 1 Shown); Wherein, the parameter of electrospinning is: spinning voltage is 25kv, and receiving distance is 25cm; The electrospun film that obtains is collected on release paper;

[0050] (3) Place the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com