Green mortar produced by building garbage and preparation method thereof

A kind of construction waste and green technology, applied in the field of building materials, can solve the problems of long time for ordinary mortar to reach the predetermined strength, not meeting the performance requirements of light weight and environmental protection, complicated construction waste disposal, etc., to meet the requirements of ensuring engineering construction, light weight, The effect of small bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

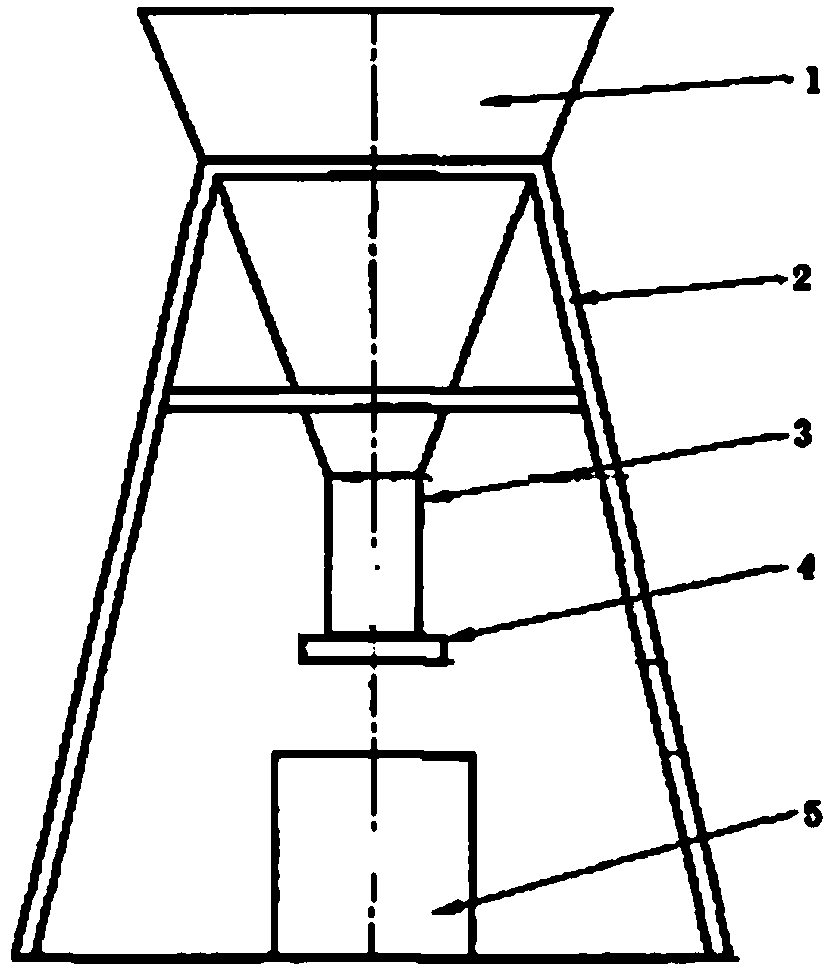

Image

Examples

Embodiment 1~6

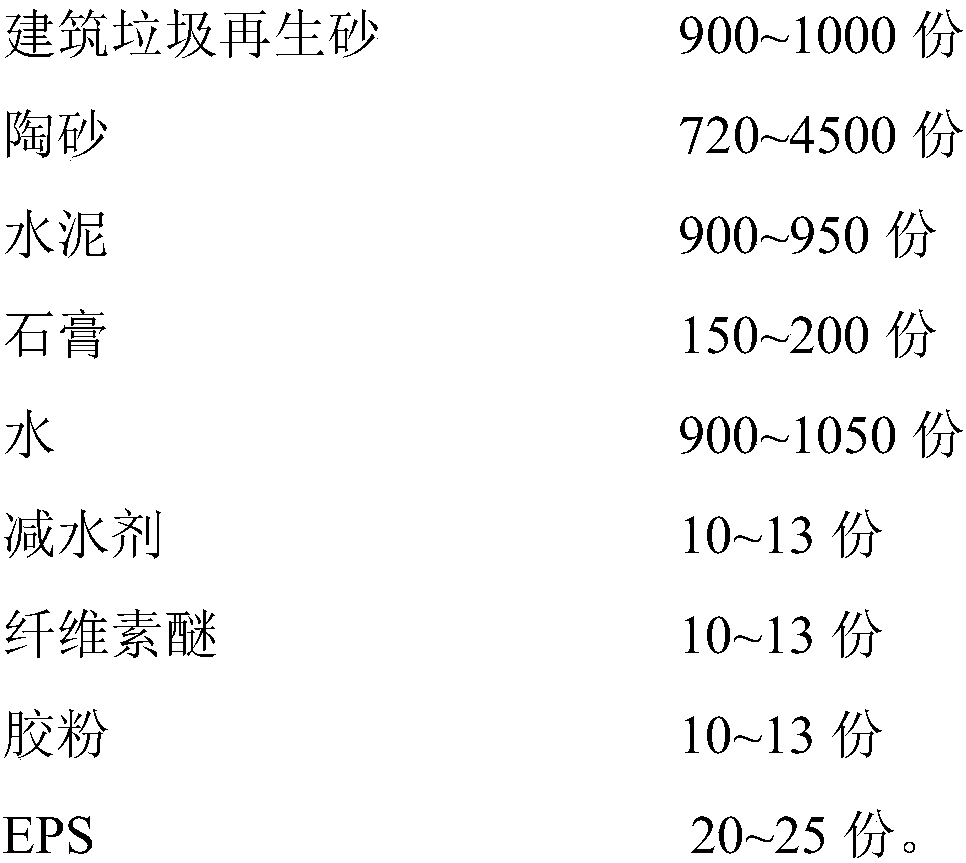

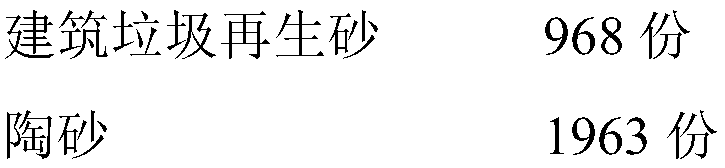

[0037] A kind of green mortar made from construction waste, the raw materials for preparation include the following components in parts by weight: regenerated sand from construction waste, cement, gypsum, pottery sand, water, water reducing agent, cellulose ether, rubber powder, EPS, specifically The component content is shown in Table 1; the raw material for the preparation of reclaimed sand from construction waste is selected from industrial waste fly ash; the fineness modulus of reclaimed sand from construction waste is 3.77, and the apparent density is 1613kg / m 3 ; The fineness modulus of pottery sand is 3.29, and the apparent density is 818kg / m 3 ; The water reducing agent is an amino high-efficiency water reducing agent; the rubber powder is a ternary copolymerization rubber powder of ethylene, polyethylene and vinyl laurate.

[0038] The preparation method of the green mortar made from construction waste in the present embodiment is:

[0039] (1) Take construction wast...

Embodiment 7~12

[0089] A kind of green mortar made from construction waste, the preparation raw material comprises the following components in parts by weight: construction waste regenerated sand, cement, gypsum, pottery sand, perlite, water, water reducing agent, cellulose ether, rubber powder, EPS, see Table 4 for specific component contents.

[0090] In the composition of raw materials, the raw materials for the preparation of construction waste recycled sand are selected from construction waste; the fineness modulus of construction waste recycled sand is 3.77, and the apparent density is 1613kg / m 3 ;The fineness modulus of pottery sand is 3.29, and the apparent density is 818kg / m 3 ; The water reducer is an amino high-efficiency water reducer; the rubber powder is a ternary copolymer rubber powder of vinyl acetate, ethylene and higher fatty acid vinyl ester.

[0091] The preparation method of the green mortar made from construction waste in the present embodiment is:

[0092] (1) Weigh ...

Embodiment 13~14

[0113] A kind of green mortar made from construction waste, the raw materials for preparation include the following components in parts by weight: regenerated sand from construction waste, cement, gypsum, pottery sand, water, water reducing agent, cellulose ether, rubber powder, EPS, specifically The component content is shown in Table 8; the raw material for the preparation of reclaimed sand from construction waste is selected from industrial waste fly ash; the fineness modulus of reclaimed sand from construction waste is 3.84, and the apparent density is 1538kg / m 3 ;The fineness modulus of pottery sand is 3.19, and the apparent density is 847kg / m 3 ; The water reducing agent is an amino high-efficiency water reducing agent; the rubber powder is a ternary copolymerization rubber powder of ethylene, polyethylene and vinyl laurate. The preparation method in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com