Infrared detector on basis of organic field-effect transistor and method for preparing infrared detector

An infrared detector and organic field technology, applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., to achieve rich content, high-sensitivity and high-response detection, and enhance the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

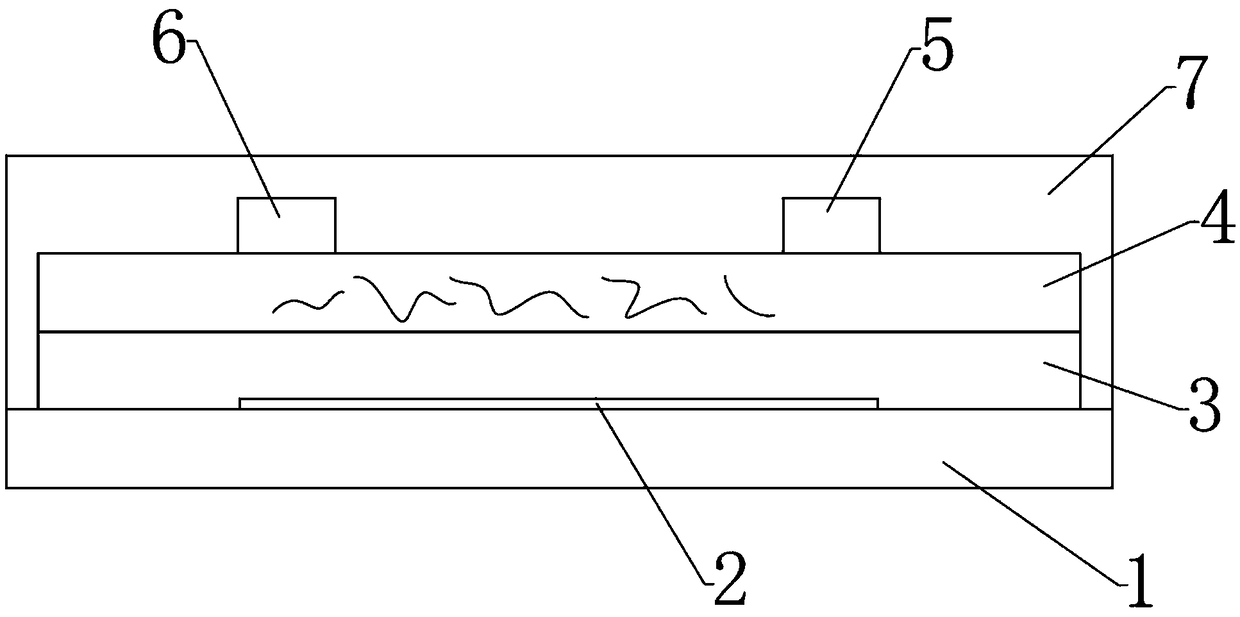

[0041] Such as figure 1 The bottom-gate top-contact structure is shown, and the material and thickness of each layer are as follows: the gate electrode, source electrode and drain electrode are all silver nanowires; the dielectric layer is made of silk fibroin with a thickness of 200nm; the organic semiconductor layer is made of carbon nanowires. The pipe is formed by mixing bamboo fibers (bamboo fiber mass fraction is 10%), and the thickness is 50nm; the shellac encapsulation layer has a thickness of 300nm. A field effect transistor infrared detector with high sensitivity and high stability can be realized by using the structure.

[0042] The preparation method of the present embodiment is as follows:

[0043] ① Clean the substrate with detergent, acetone solution, deionized water and isopropanol solution, and dry it with nitrogen after cleaning;

[0044] ② Prepare a 30nm thick silver nano wire grid electrode on the surface of the substrate;

[0045] ③The silk fibroin solu...

Embodiment 2

[0050] Such as figure 1 The bottom-gate top-contact structure is shown, and the material and thickness of each layer are as follows: the gate electrode, source electrode and drain electrode are all gold nanowires; the dielectric layer is made of silk fibroin with a thickness of 500nm; the organic semiconductor layer is 3- Hexylthiophene is mixed with bamboo fiber (the mass fraction of bamboo fiber is 5%), and the thickness is 30nm; the shellac encapsulation layer has a thickness of 200nm. A field effect transistor infrared detector with high sensitivity and high stability can be realized by using the structure.

[0051] The preparation method of the present embodiment is as follows:

[0052] ① Clean the substrate with detergent, acetone solution, deionized water and isopropanol solution, and dry it with nitrogen after cleaning;

[0053] ② Prepare a 30nm thick gold nano wire grid electrode on the surface of the substrate;

[0054] ③The silk fibroin solution with a concentrat...

Embodiment 3

[0059] Such as figure 1 The bottom-gate top-contact structure is shown, and the material and thickness of each layer are as follows: the gate electrode, source electrode and drain electrode are all iron nanowires; the dielectric layer is silk fibroin with a thickness of 600nm; the organic semiconductor layer is 6, 13-bis(triisopropylsilylethynyl) pentacene is mixed with bamboo fiber (the mass fraction of bamboo fiber is 8%), the thickness is 40nm, and the shellac encapsulation layer has a thickness of 200nm. A field effect transistor infrared detector with high sensitivity and high stability can be realized by using the structure.

[0060] The preparation method of the present embodiment is as follows:

[0061] ① Clean the substrate with detergent, acetone solution, deionized water and isopropanol solution, and dry it with nitrogen after cleaning;

[0062] ② Prepare a 30nm thick iron nano wire grid electrode on the surface of the substrate;

[0063] ③The silk fibroin soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com