A dry dehydration and deashing process of coal with full particle size

A full-grain, dry technology, used in wet separation, chemical instruments and methods, solid separation, etc., can solve the problems of high sorting lower limit, low medium utilization rate, low sorting accuracy, etc., to avoid dust spillage. The effect of dust, low investment and operating costs, and reduced cost expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

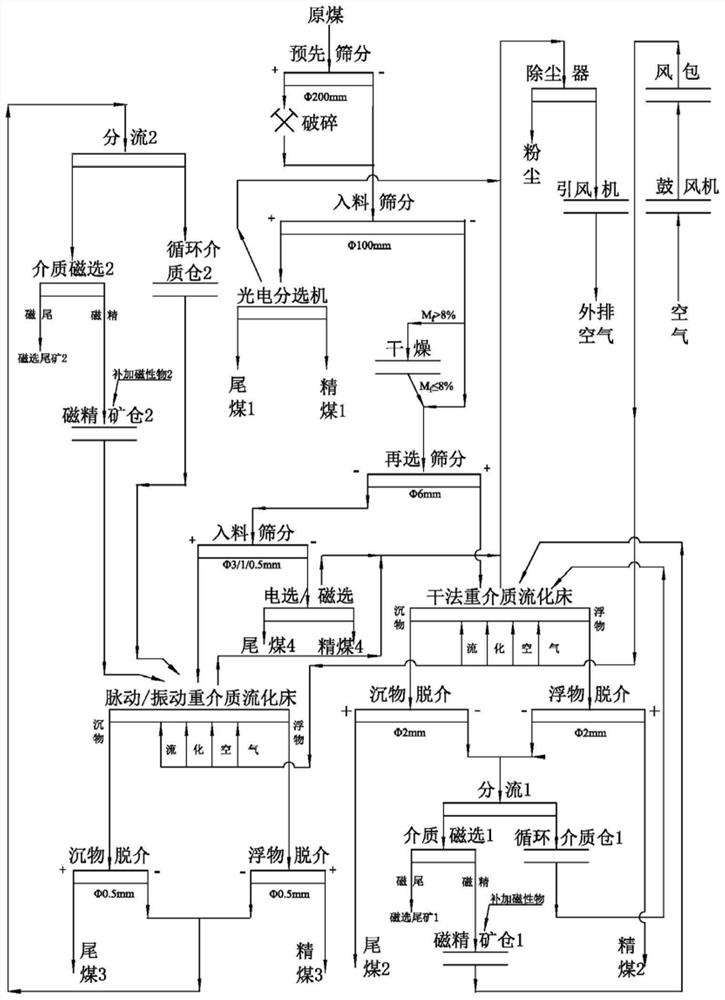

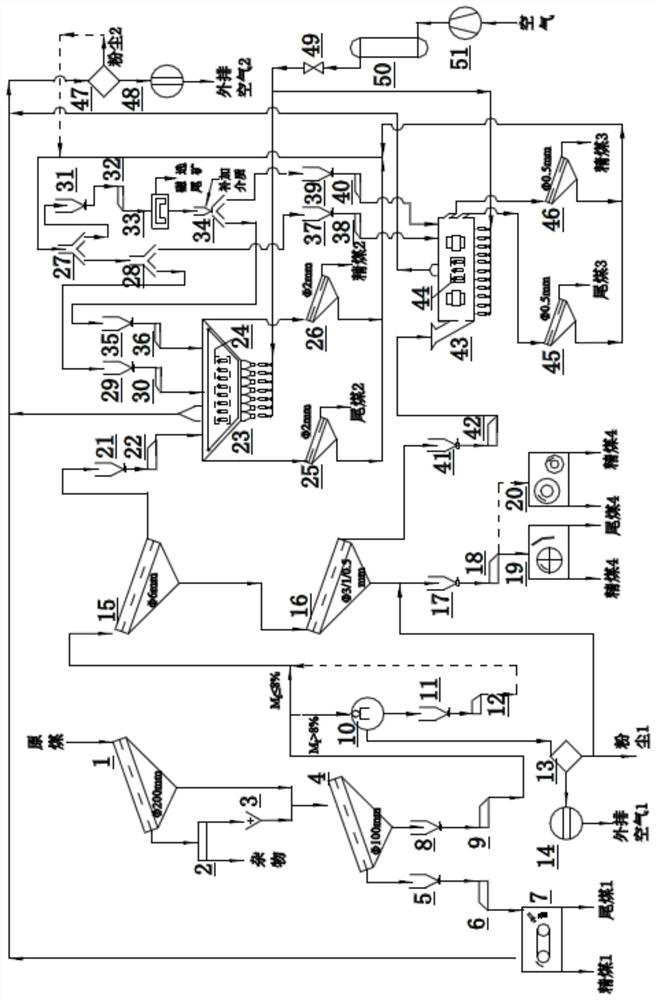

[0037] Such as figure 1 Shown, a kind of technique of dry dehydration and deashing of coal full-grain grade of the present invention comprises the following steps:

[0038] (1) Raw coal preparation and drying: The incoming coal from the mine or coal storage yard is first graded through a grading sieve with an aperture of 200mm. The +200mm raw coal on the sieve is crushed to -200mm by a crusher, and mixed with the -200mm raw coal under the sieve. 100mm grading sieve II sieving; the under-sieve, that is, -100mm raw coal with an external moisture Mf higher than 8% is pre-dried, and the moisture is lowered to below 8% and then discharged from the dryer, and the -100mm raw coal external moisture Mf is lower than 8% % go directly to the next step;

[0039] (2) Sorting raw coal: the 100mm grading sieve II sieve material, that is, 100-200mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com