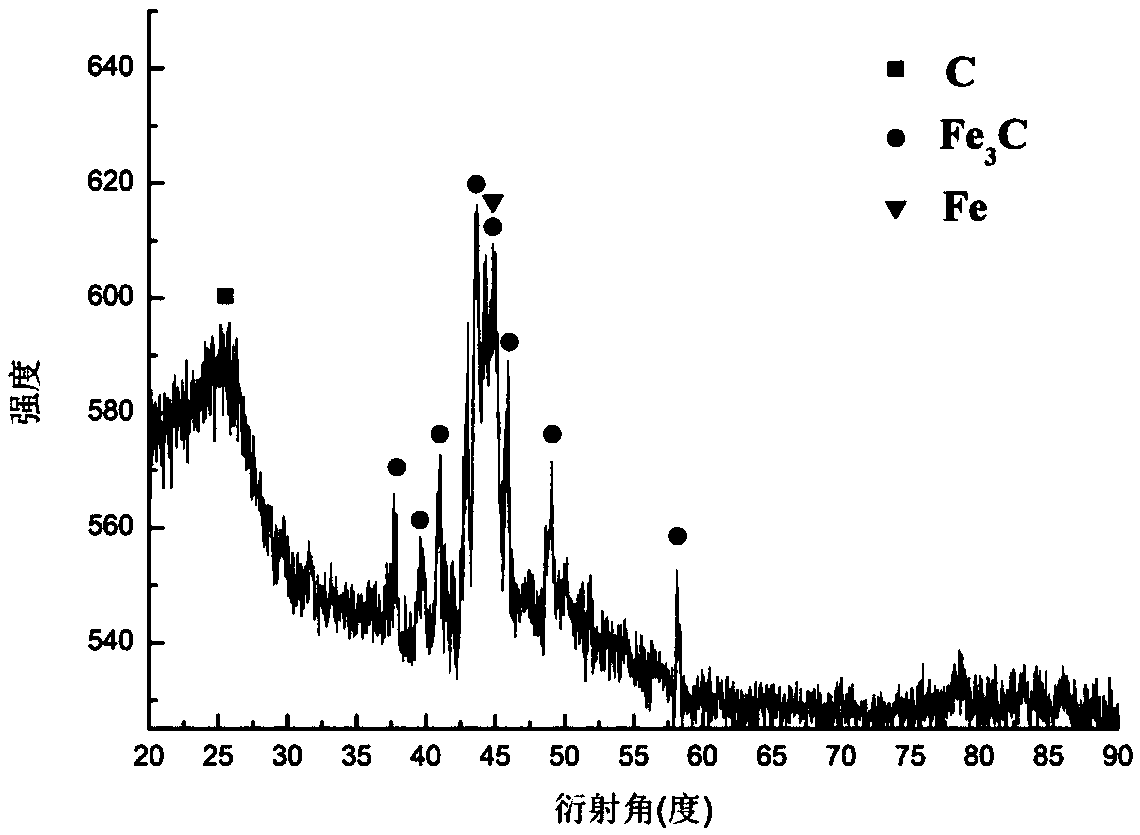

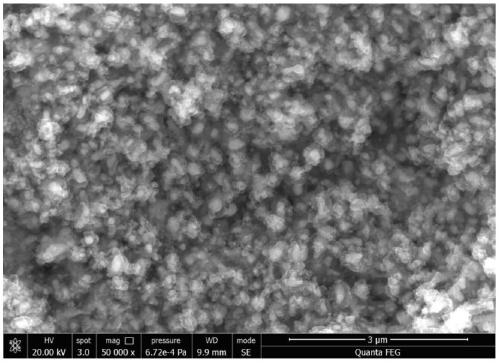

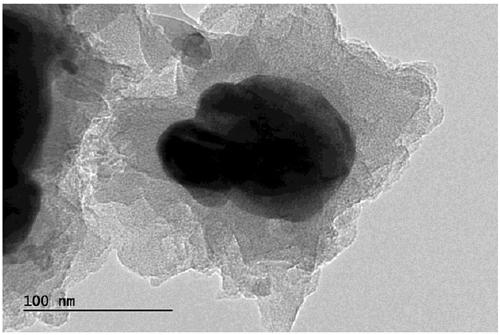

Method for preparing carbon coated iron-cementite magnetic nanopaticles

A magnetic nanoparticle, iron carbide technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for material and surface science, can solve the problems of low particle crystallization, poor stability, low purity, etc. Removal, good stability, the effect of meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The first step is to prepare the iron oxide-potassium bromide catalyst precursor:

[0055] First, the ferric citrate pentahydrate aqueous solution with a mass percentage concentration of 3% and the potassium bromide aqueous solution with a mass percentage concentration of 10.03% are mixed to form a mixed solution, ensuring that the mass ratio of iron to potassium bromide is 0.05: 1, using magnetic heating The stirrer heated and stirred the above mixed solution at 70°C at a speed of 500rpm for 4h, then transferred it to a plastic test tube and placed it in a freeze drying oven, and cooled it down to -50°C at a cooling rate of 20°C / min, and the above mixed solution was frozen into After the solid state, continue to dry in a freeze-drying box under a vacuum of 1.3Pa for 48h, then take out the ferric citrate particles obtained after freeze-drying and evenly distributed on the surface of the potassium bromide carrier as the iron metal source from the plastic test tube, use th...

Embodiment 2

[0061] The first step is to prepare the iron oxide-potassium bromide catalyst precursor:

[0062] First, the ferric citrate pentahydrate aqueous solution with a mass percentage concentration of 2% and the potassium bromide aqueous solution with a mass percentage concentration of 11.14% are mixed to form a mixed solution, ensuring that the mass ratio of iron to potassium bromide is 0.03:1, and using magnetic heating The stirrer heated and stirred the above mixed solution at 60°C at a speed of 400rpm for 3h, then transferred it to a plastic test tube and placed it in a freeze-drying oven, and cooled it down to -30°C at a cooling rate of 15°C / min, and the above mixed solution was frozen into After the solid state, continue to dry in a freeze-drying box under a vacuum of 8 Pa for 36 hours, then take out the ferric citrate particles obtained after freeze-drying and evenly distributed on the surface of the potassium bromide carrier as an iron metal source from the plastic test tube, ...

Embodiment 3

[0073] The first step is to prepare the iron oxide-potassium bromide catalyst precursor:

[0074] First, the ferric citrate pentahydrate aqueous solution with a mass percentage concentration of 1% and the potassium bromide aqueous solution with a mass percentage concentration of 16.7% are mixed to form a mixed solution, ensuring that the mass ratio of iron to potassium bromide is 0.01: 1, using magnetic heating The stirrer heated and stirred the above mixed solution at 50°C at a speed of 300rpm for 2h, then transferred it to a plastic test tube and placed it in a freeze-drying oven, and cooled it down to -10°C at a cooling rate of 5°C / min, and the above mixed solution was frozen into After the solid state, continue to dry in a freeze-drying box under a vacuum of 13.0Pa for 24h, then take out the ferric citrate particles obtained after freeze-drying and evenly distributed on the surface of the potassium bromide carrier as an iron metal source from the plastic test tube, and use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com