Preparation of a molybdenum ditelluride nanowire material and molybdenum ditelluride nanowire material

A molybdenum ditelluride and nanowire technology, which is applied in the field of nanomaterials, can solve problems such as unsynthesized molybdenum ditelluride nanowires and the like, and achieve the effect of a simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing molybdenum ditelluride nanowires on a silicon dioxide / silicon substrate, comprising the following steps:

[0032] Step 1: Cut the silica / silicon substrate into a 1cm*3cm sheet and blow it off with an air gun;

[0033] Step 2: Grind molybdenum powder and tellurium powder at a molar ratio of 1:4, mix well, place 2 mg of mixed powder on a silicon dioxide / silicon substrate, and add 0.1 mg of sodium chloride; A silicon dioxide / silicon substrate, SiO 2 Face down, upside down on the wafer;

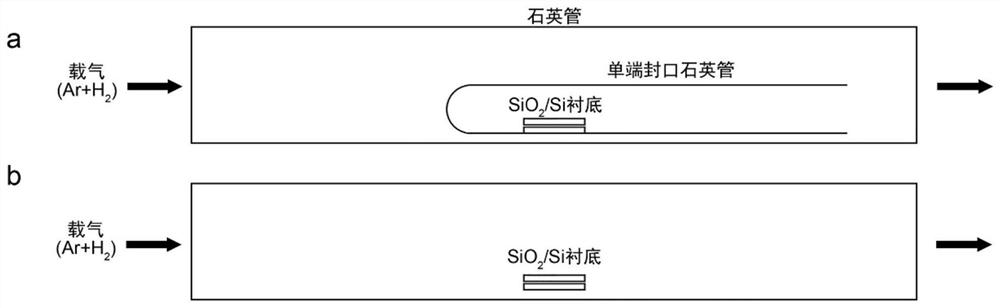

[0034] Step 3: Place two silica / silicon substrates in a quartz tube with an inner diameter of 1.2 mm and one-end sealing, place the single-end-sealed quartz tube at the heating center of the tube atmosphere furnace, and single-end-seal the quartz tube The opening faces the side of the exhaust port, such as figure 1 as shown in a.

[0035] Step 4: Infuse 100 sccm of argon gas for 30 minutes to completely remove residual oxygen in the tube....

Embodiment 2

[0038] This embodiment provides a method for preparing molybdenum ditelluride nanowires on a silicon dioxide / silicon substrate, comprising the following steps:

[0039] Step 1: Cut the silica / silicon substrate into a 1cm*3cm sheet and blow it off with an air gun;

[0040] Step 2: Grind molybdenum powder and tellurium powder at a molar ratio of 1:12, mix them evenly, place 3 mg of mixed powder on a silicon dioxide / silicon substrate, and add 0.2 mg of sodium chloride; A silicon dioxide / silicon substrate, SiO 2 Face down, upside down on the wafer;

[0041] Step 3: Place two silica / silicon substrates in a quartz tube with an inner diameter of 1.2 mm and one-end sealing, place the single-end-sealed quartz tube at the heating center of the tube atmosphere furnace, and single-end-seal the quartz tube The opening faces the side of the exhaust port, such as figure 1 as shown in a.

[0042] Step 4: Infuse 100 sccm of argon gas for 30 minutes to completely remove residual oxygen in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com