Porous carbon material prepared by self-modification of Bacillus and preparation method and application thereof

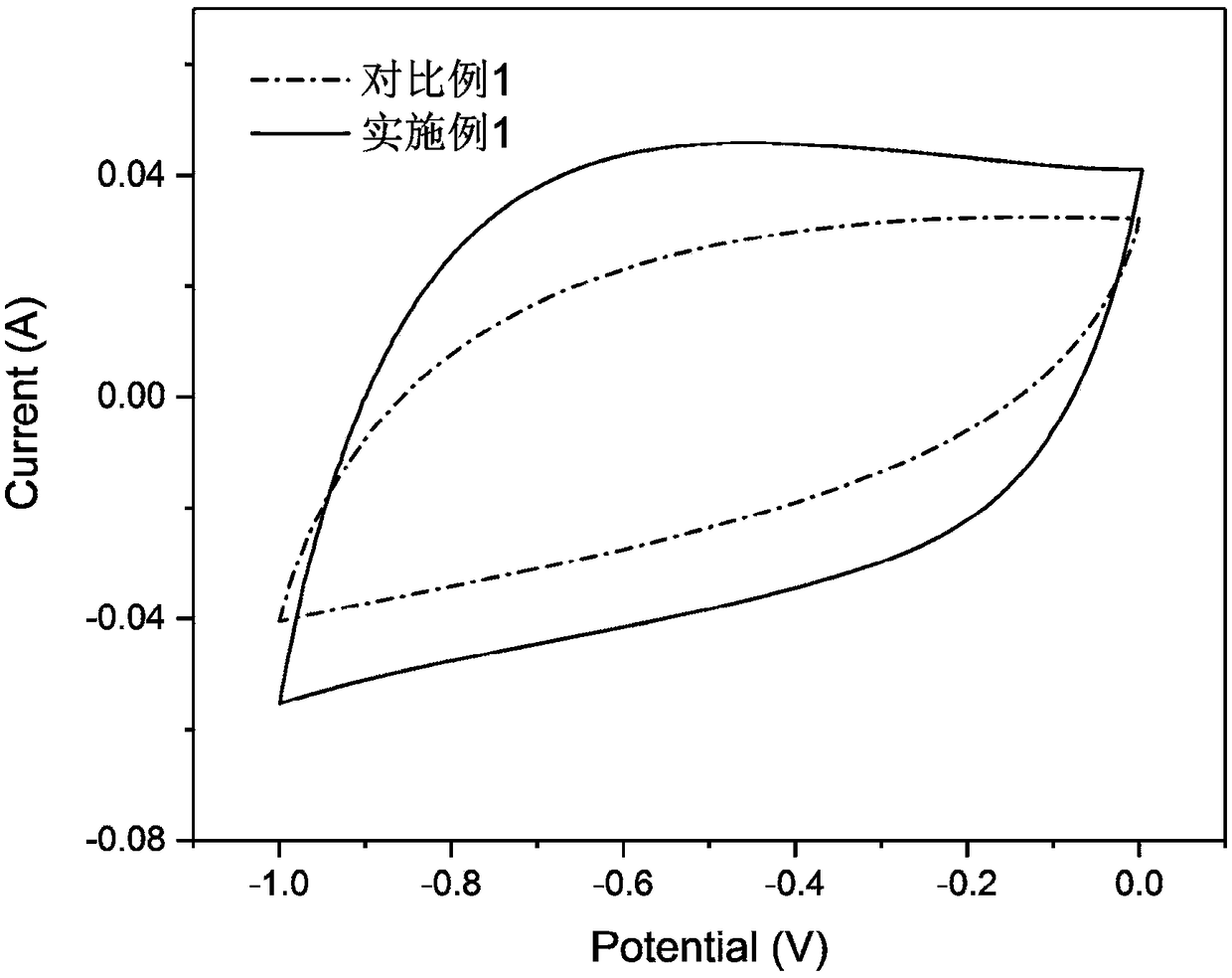

A porous carbon material, Bacillus technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of long cultivation time, strong corrosion, environmental pollution, etc., and achieve low cost and high specific capacitance , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

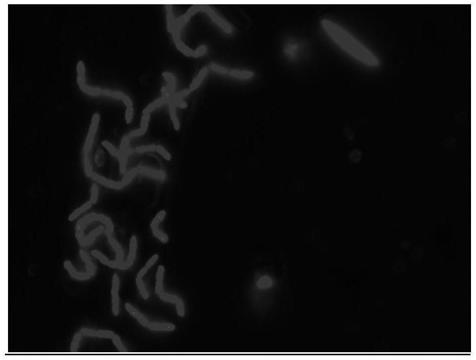

[0051] (1) Inoculate the Bacillus megaterium B-10 thalli stored on the LB slope into the LB liquid medium, and cultivate it for 18 hours at a temperature of 30° C. to obtain the seed liquid of Bacillus megaterium B-10; wherein the LB liquid medium The distribution ratio of each component is: peptone 10g, yeast powder 5g, sodium chloride 10g, distilled water 1L; the LB slope is based on the above formula with the addition of 15g / L agar;

[0052] (2) Centrifuge the Bacillus megaterium B-10 seed liquid obtained under the condition of 8000rpm for 5 minutes, discard the supernatant, and collect the thalline;

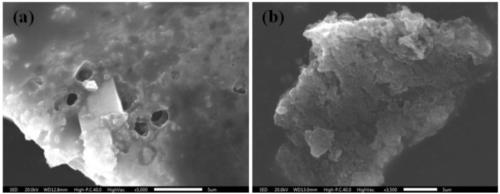

[0053] (3) Inoculate the collected Bacillus megaterium B-10 cells into high-nitrogen glucose medium at 2% inoculum size (the ratio of the volume of the transferred bacterial solution to the volume of the culture solution after inoculation), and at a temperature of 30°C, naturally pH, cultivated for 24h, and precipitated and separated to obtain bacterial thallus; wherein the r...

Embodiment 2

[0064] (1) Cultivate according to steps (1) and (2) in Example 1 to obtain the seed liquid of Bacillus megaterium B-10.

[0065] (2) Centrifuge the Bacillus megaterium B-10 seed liquid obtained under the condition of 8000rpm for 5 minutes, discard the supernatant, and collect the thalline;

[0066] (3) The collected Bacillus megaterium B-10 cells were inoculated in a high-nitrogen glucose medium at a 10% inoculum amount, cultured for 24 hours at a temperature of 30° C., at a natural pH, and separated by precipitation to obtain bacterial cells; wherein The proportion of each component of the high nitrogen glucose medium is: glucose 4g / L, (NH 4 ) 2 SO 4 4g / L, K 2 HPO 4 1g / L, KH 2 PO 4 1g / L, MgSO 4 ·7H 2 O0.2g / L, CaCl 2 0.01g / L, FeSO 4 ·7H 2 O 0.015g / L, MnSO 4 ·H 2 O 0.01g / L.

[0067] (4) Place the Bacillus megaterium B-10 thalline obtained in the previous step in a vacuum freeze dryer to obtain dry thalline to constant weight.

[0068] (5) Place the dried bacte...

Embodiment 3

[0072] (1) Cultivate according to steps (1) and (2) in Example 1 to obtain the seed liquid of Bacillus megaterium B-10.

[0073] (2) Centrifuge the Bacillus megaterium B-10 seed liquid obtained under the condition of 8000rpm for 5 minutes, discard the supernatant, and collect the thalline;

[0074] (3) The collected Bacillus megaterium B-10 cells were inoculated in a high-nitrogen glucose medium at a 5% inoculum amount, cultured for 36 hours at a temperature of 30° C., at a natural pH, and separated by precipitation to obtain bacterial cells; wherein the The proportion of each component of the high nitrogen glucose medium is: glucose 4g / L, (NH 4 ) 2 SO 4 6g / L, K 2 HPO 4 1g / L, KH 2 PO 41g / L, MgSO 4 ·7H 2 O0.2g / L, CaCl 2 0.01g / L, FeSO 4 ·7H 2 O 0.015g / L, MnSO 4 ·H 2 O 0.01g / L;

[0075] (4) Place the Bacillus megaterium B-10 thalline obtained in the previous step in a vacuum freeze dryer to obtain dry thalline to constant weight.

[0076] (5) Place the dried bact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com