Cosmetic with bird's nest active extract liquid, method for preparing same and application of cosmetic

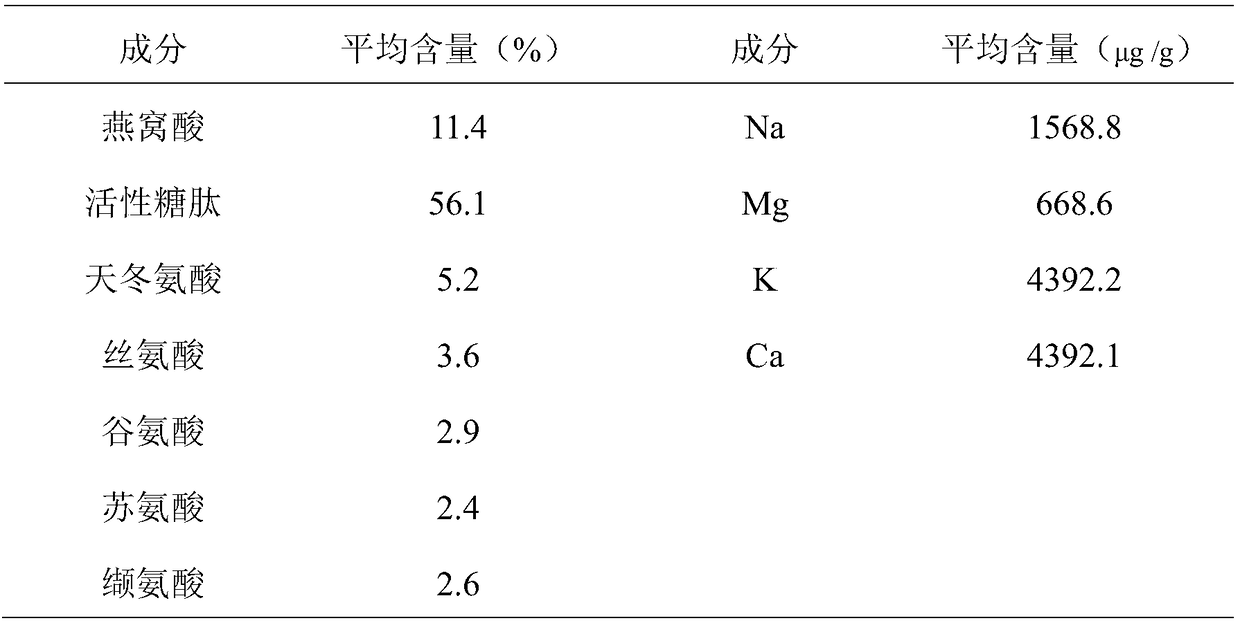

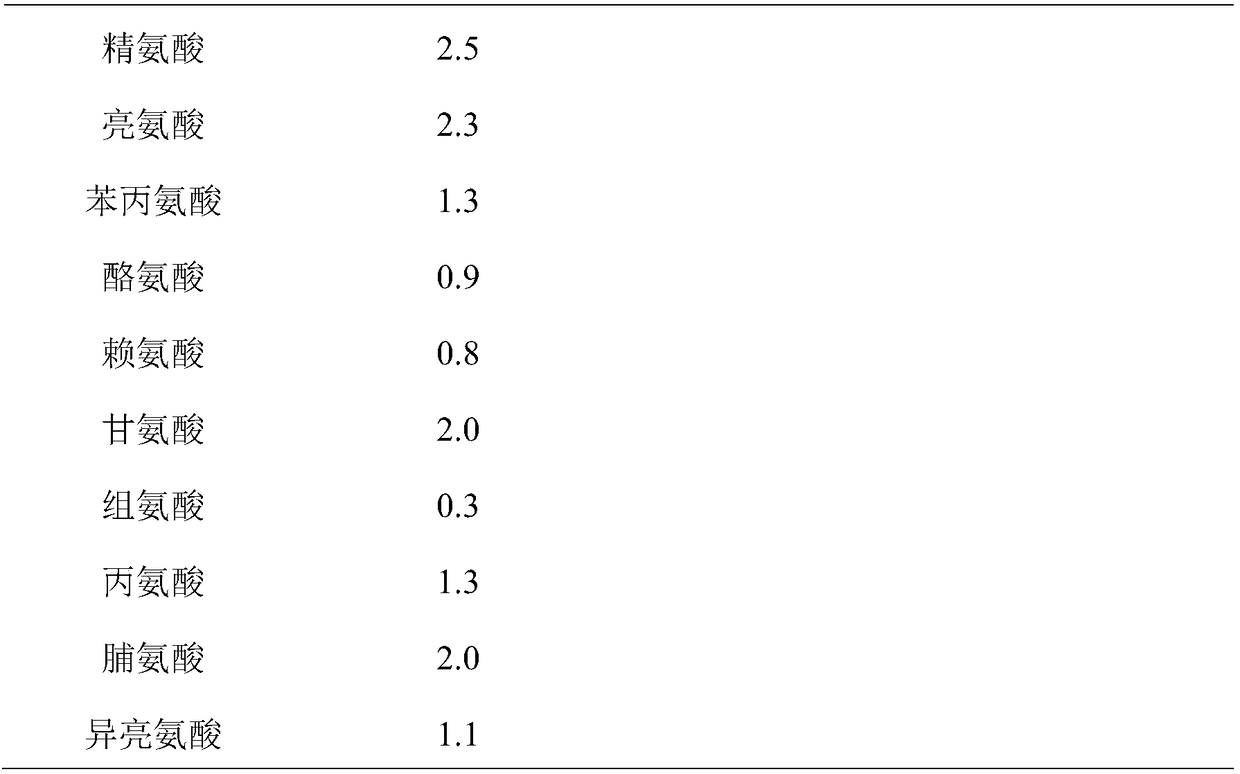

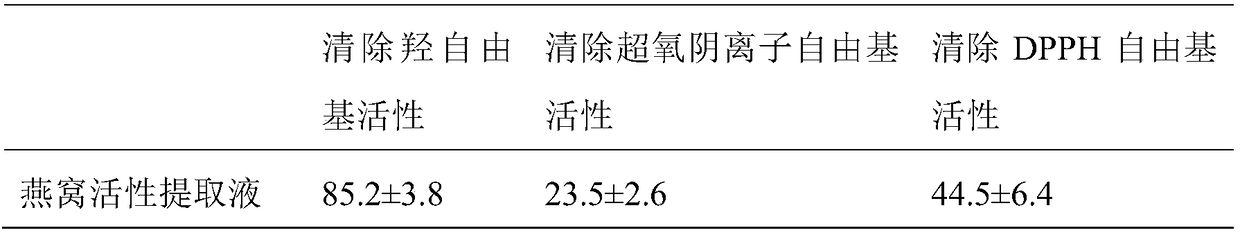

A technology for extraction and cosmetics, which is applied in the field of cosmetics containing bird's nest active extract, which can solve the problems of inconspicuousness, scarcity of cosmetics, and single function, and achieve the effects of less loss of active substances, improvement of skin blemishes, and simplified extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take an appropriate amount of edible bird’s nest that meets the relevant standards for the use of bird’s nest in my country, add 19 times the quality of water, soak for 1 hour, high-speed shear at room temperature for 5 minutes, and the speed is 40000r / min, heat to 50°C, and at the same time high-speed shear, speed 40000r / min, keep 5min, remove bird's nest hair and impurity by gauze filtration while hot, make bird's nest active extract (aqueous solution) after ultrafiltration, the content of bird's nest active component is 4.5%, stand-by.

[0018] Preparation of the oil phase: raw materials in parts by mass: 3 cetearyl alcohols, 2 monoglycerides, 3 shea butter, 2 polydimethylsiloxanes, and 10 glycerol tri(ethylhexanoate). Mix the above substances, stir and heat to 75-80°C, dissolve and obtain an oil phase, which is ready for use.

[0019] Preparation of the water phase: raw materials in parts by mass, bird's nest active extract 22, deionized water 46.5, glycerin 3, propy...

Embodiment 2

[0023] Take an appropriate amount of edible bird’s nest that meets the relevant standards for the use of bird’s nest in my country, add 99 times the quality of water, soak it for 2 hours, shear at room temperature for 20 minutes at a high speed, and the speed is 25000r / min, heat it to 75°C, and at the same time high speed shear, speed Keep it at 25000r / min for 20 minutes, remove bird hair and impurities by gauze filtration while it is hot, and obtain bird's nest active extract (aqueous solution) after ultrafiltration, the content of bird's nest active components is 0.9%, and it is ready for use.

[0024] Preparation of the oil phase: raw materials in parts by mass: 1.5 cetearyl alcohol, 1 monoglyceride, 2 polydimethylsiloxane, 3 dioctyl carbonate, and 5 glycerol tri(ethylhexanoate). Mix the above substances, stir and heat to 75-80°C, dissolve and obtain an oil phase, which is ready for use.

[0025] Preparation of water phase: raw materials in parts by mass, bird’s nest active ...

Embodiment 3

[0029] Take an appropriate amount of edible bird’s nest that meets the relevant standards for the use of bird’s nest in my country, add 199 times the quality of water, soak for 3 hours, high-speed shear at room temperature for 30 minutes, and the speed is 10000r / min, heat to 100°C, and at the same time, high-speed shear, speed Keep it at 10000r / min for 30 minutes, remove bird hair and impurities by gauze filtration while it is hot, and obtain bird's nest active extract (aqueous solution) after ultrafiltration, the content of bird's nest active components is 0.45%, and it is ready for use.

[0030] Preparation method: raw materials in parts by mass, bird's nest active extract 11, sodium hyaluronate 0.1, butanediol 3, glycerin 3, deionized water 79.03, propylene glycol 3, chlorphenesin 0.2, methyl ester 0.1, phenoxy Ethanol 0.25, solubilizer 0.3, essence 0.02. Add bird's nest active extract and glycerin to deionized water, stir and heat to 80-90°C, keep for 20min to sterilize, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com